Drilling Rig System and Drilling Method Based on Dynamic Control of Adaptive Downhole Drill Tool Face

A dynamic control and tool face technology, applied in drilling automatic control systems, drilling equipment, directional drilling, etc., can solve problems such as effective control of difficult drilling tools tool face and wellbore trajectory, reducing work efficiency, affecting drilling progress, etc. Achieve simple and fast measurement or estimation, reduce accuracy requirements, and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

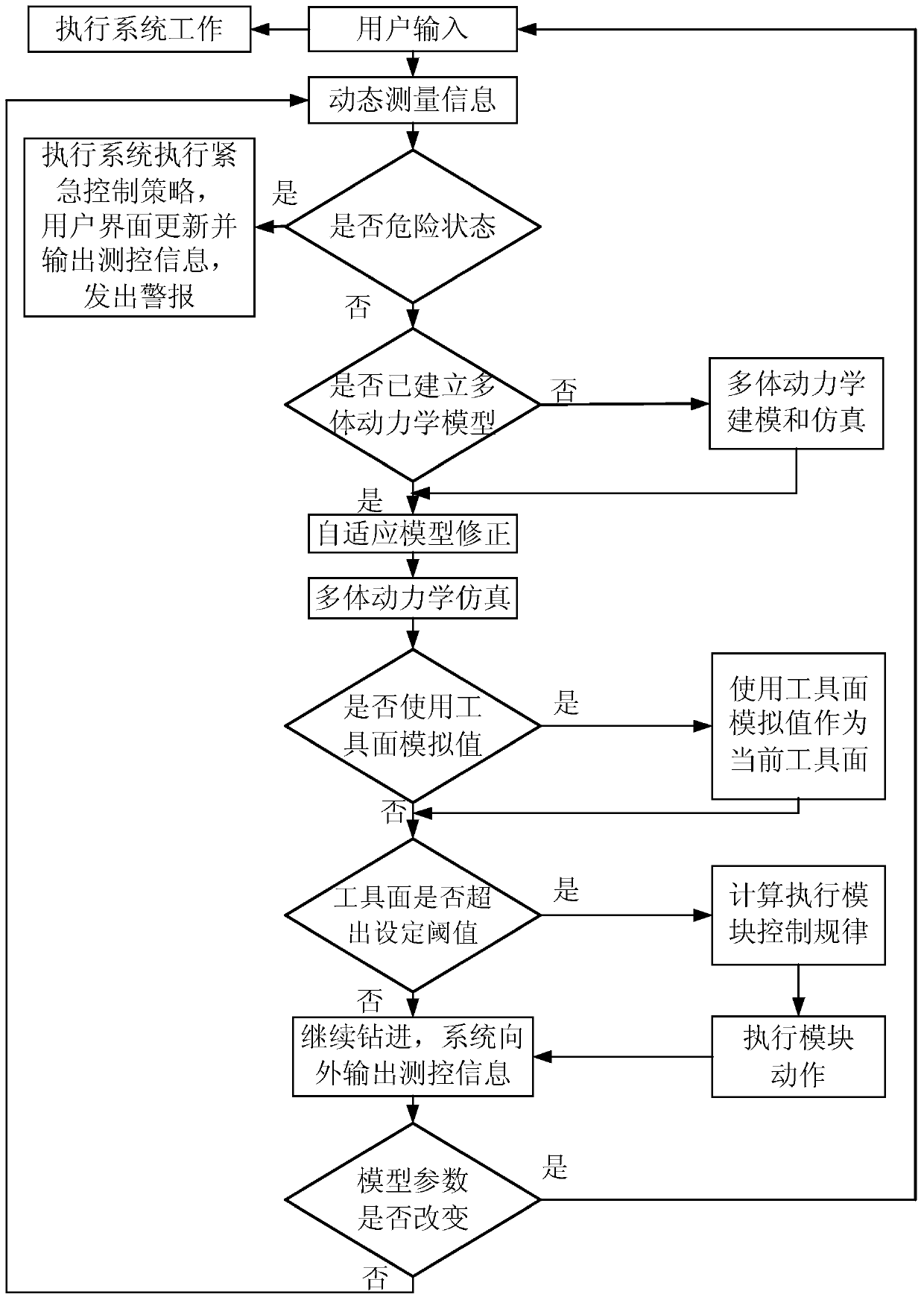

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

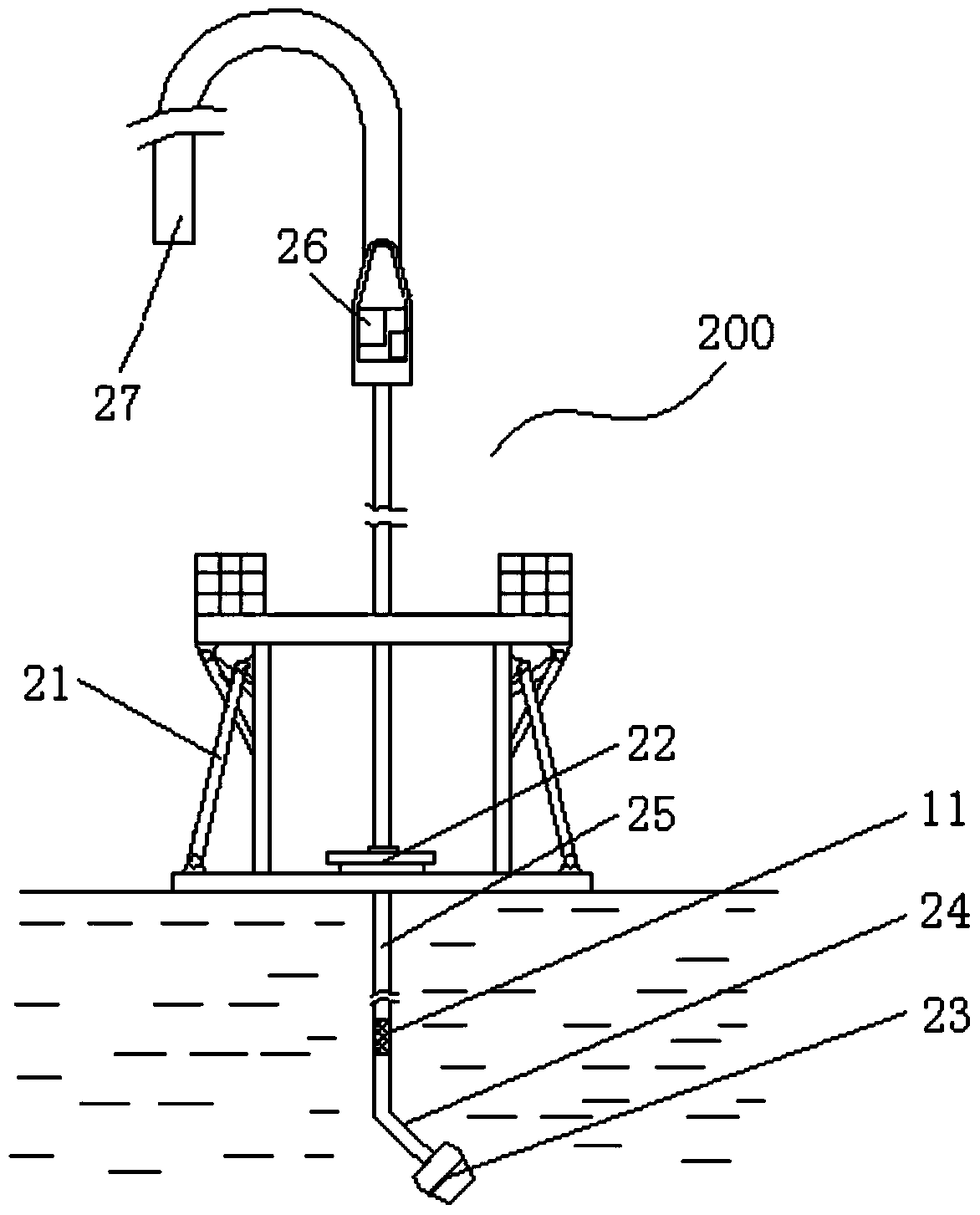

[0049] Such as figure 1 , figure 2 As shown, the drilling rig system of the present invention includes a dynamic control system 100 and a drilling system 200 .

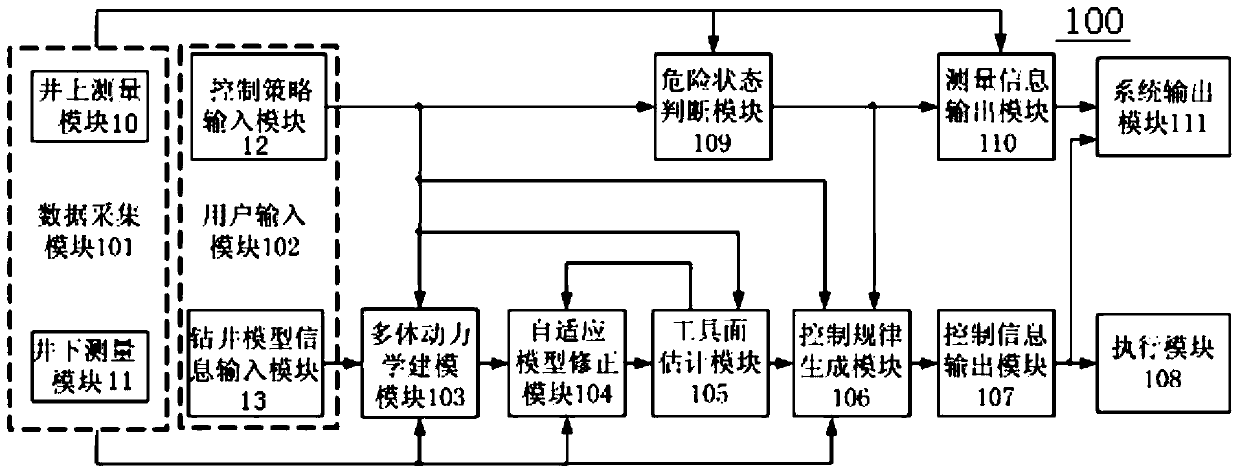

[0050] Such as figure 1 As shown, the dynamic control system 100 includes a data acquisition module 101, a user input module 102, a multi-body dynamics modeling module 103, an adaptive model correction module 104, a tool face estimation module 105, a control law generation module 106, and a control information output module 107 , an execution module 108 , a dangerous state judging module 109 , a measurement information output module 110 and a system output module 111 .

[0051] Among them, the data collection module 101 transmits the collected working state measurement information of the drilling system to the multibody dynamics modeling module 103, the adaptive model correction module 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com