Automatic operating device for hydraulic tongs

A technology of automatic operation and hydraulic tongs, which is applied to drilling equipment, earthwork drilling, drilling pipes, etc. It can solve the problems of high labor intensity and high risk, achieve high automation, improve safety factor, and improve work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

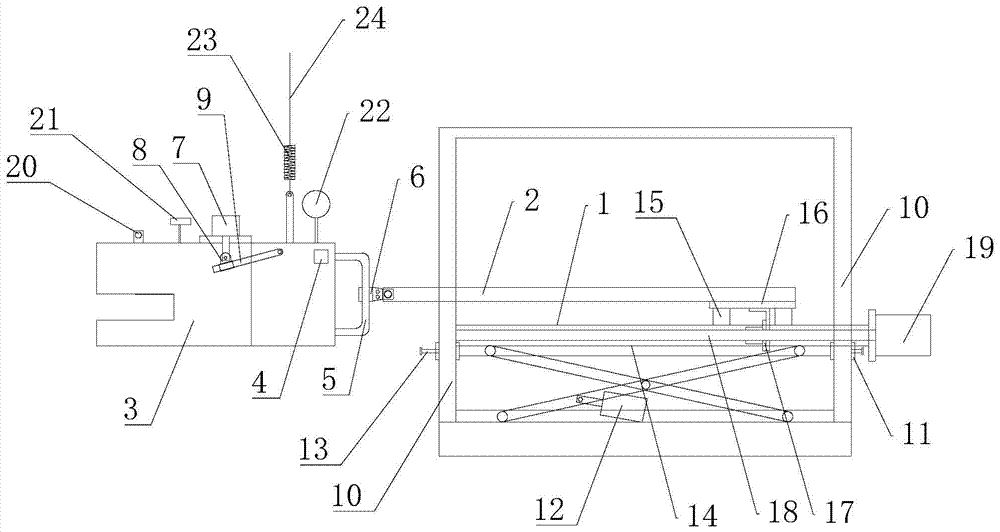

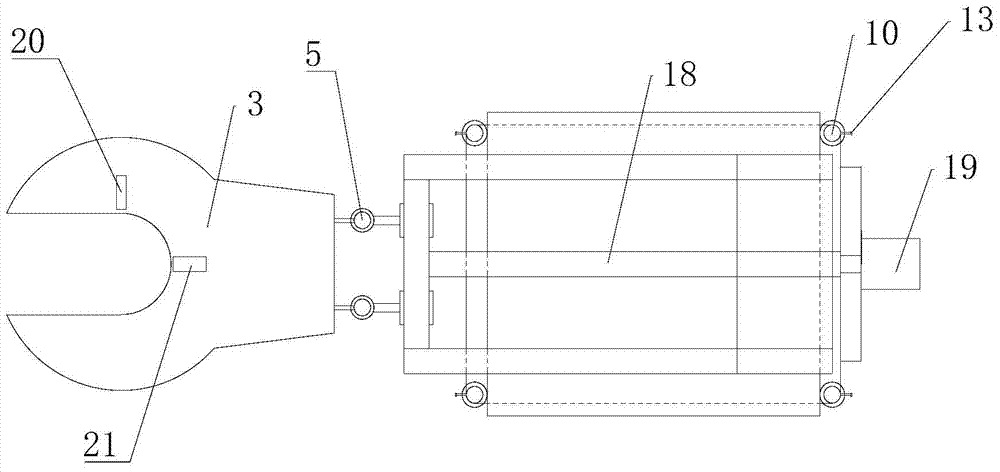

[0030] figure 1 with figure 2 As shown, the hydraulic clamp automatic operating device of the present invention includes a lifting platform 14, which can move in the vertical direction; a telescopic arm 2, which is arranged on the lifting platform 14 and can move with the The lifting platform 14 moves up and down, and the telescopic arm 2 protrudes horizontally and can reciprocate along its length direction. The end of the telescopic arm 2 is provided with a hydraulic clamp body 3, and the hydraulic clamp body 3 is provided with a The reversing cylinder 4, the hydraulic pliers body 3 still uses the original suspension method (suspended by the spring 23 and the suspension rope 24), and the hydraulic pliers body 3 is arranged at the end of the telescopic arm 2.

[0031] A cylinder—the shift cylinder 7 is installed above the shift lever 9 of the hydraulic pliers body 3. In order to realize shifting flexibly, a rotating sliding sleeve 8 is designed to connect the shift cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com