Roller replacing device and method for replacing in-furnace roller components

A roll changing device and inner roll technology, applied in the field of iron and steel metallurgy, can solve the problems of high maintenance environment temperature, limited operation space, high labor intensity, etc., and achieve the effect of reducing labor intensity, improving general-purpose and effective maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

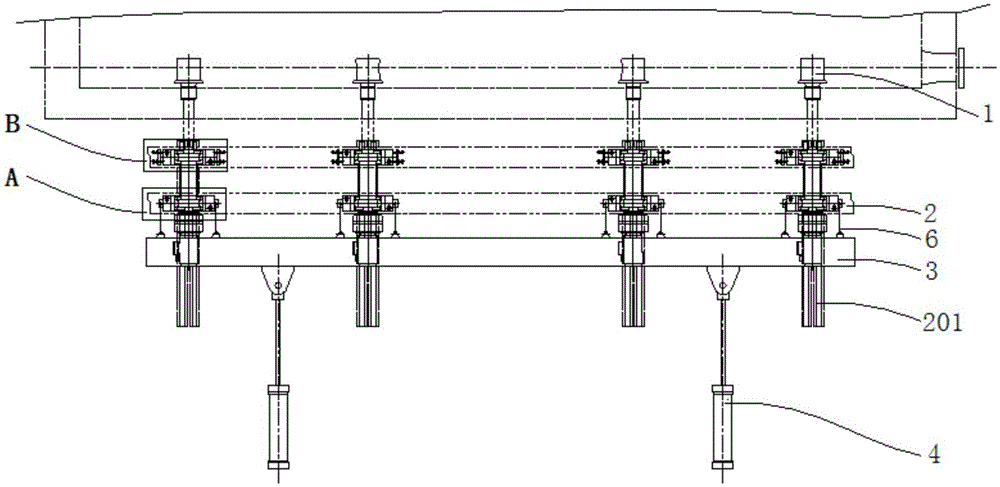

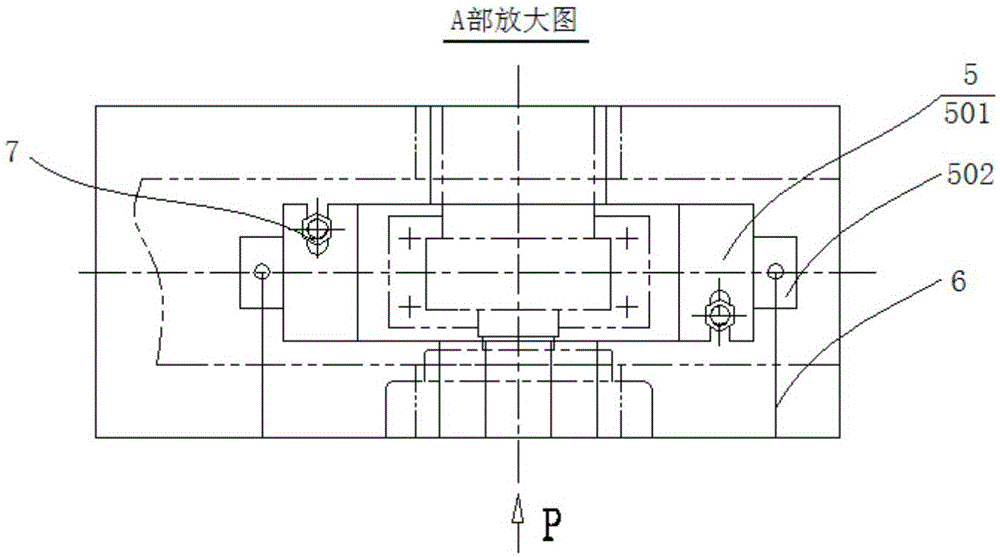

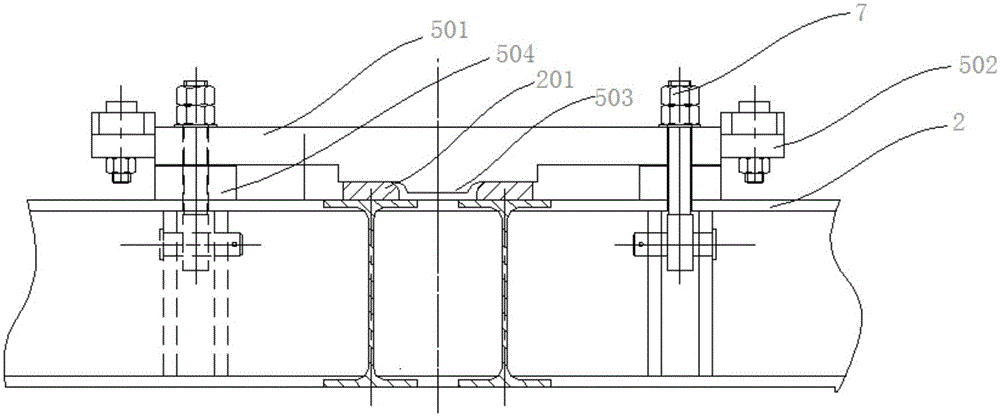

[0032] Such as Figure 1-6 Shown: a roll changing device for changing the roller assembly in the furnace, including a roller table frame 2, a roll changing beam 3 and a transmission device, and the roll changing beam 3 is slidably arranged on the roller table frame 2 through the transmission device , the transmission device is set to at least two, and each of the furnace roller assemblies 1 is provided with a roll changing base 5, and the rolling changing base 5 is slidably arranged on the roller table frame 2, and the rolling changing base 5 A telescopic connection mechanism 6 is arranged between the base 5 and the roller changing beam 3;

[0033]In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com