Method for purifying sodium dehydroacetate

A technology of sodium dehydroacetate and supercritical fluid, which is applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of product purity not meeting the requirements, poor control of cooling temperature, and low yield, so as to improve the safety of crystallization The effect of high stability, easy control of operating parameters, and fast dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

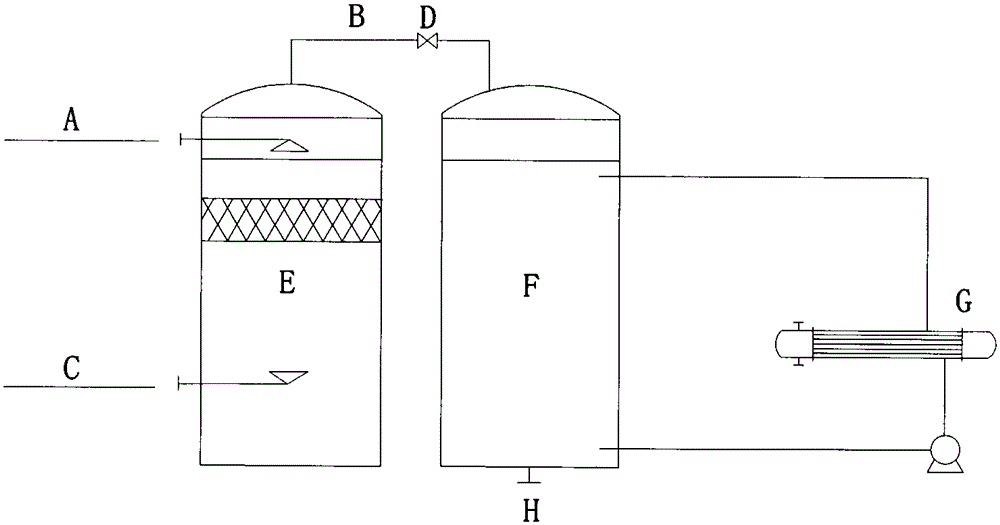

[0020] (1) Use the raw material pump to spray the neutralized 90°C dehydroacetate solution A containing impurities from the top of the extraction tower E, and at the same time, feed the supercritical fluid CO at the bottom of the extraction tower E 2 C, control supercritical fluid temperature to 33°C, pressure to 9Mpa, flow rate to 15m 3 / min, so that sodium dehydroacetate is dissolved in supercritical fluid CO 2 C;

[0021] (2) High-pressure supercritical fluid CO containing dissolved sodium dehydroacetate 2 B is reduced to a pressure lower than the supercritical fluid CO through the throttle valve D 2 Enter the separation tank F below the critical pressure; supercritical fluid CO 2 The solubility drops sharply and the solute is precipitated, which is separated into two parts: sodium dehydroacetate solution H and supercritical fluid gas. The former is a process product, which is released from the bottom of the separation tank F regularly, and the latter is a circulating ga...

Embodiment 2

[0024] (1) Use the raw material pump to spray the neutralized 90°C dehydroacetate solution A containing impurities from the top of the extraction tower E, and at the same time, feed the supercritical fluid CO at the bottom of the extraction tower E 2 C, control supercritical fluid temperature to 34°C, pressure to 10Mpa, flow rate to 17m 3 / min, so that sodium dehydroacetate is dissolved in supercritical fluid CO 2 C;

[0025] (2) High-pressure supercritical fluid CO containing dissolved sodium dehydroacetate 2 B is reduced to a pressure lower than the supercritical fluid CO through the throttle valve D 2 Enter the separation tank F below the critical pressure; supercritical fluid CO 2 The solubility drops sharply and the solute is precipitated, which is separated into two parts: sodium dehydroacetate solution H and supercritical fluid gas. The former is a process product, which is released from the bottom of the separation tank F regularly, and the latter is a circulating g...

Embodiment 3

[0028] (1) Use the raw material pump to spray the neutralized 90°C dehydroacetate solution A containing impurities from the top of the extraction tower E, and at the same time, feed the supercritical fluid CO at the bottom of the extraction tower E 2 C, control supercritical fluid temperature to 36°C, pressure to 11Mpa, flow rate to 20m 3 / min, so that sodium dehydroacetate is dissolved in supercritical fluid CO 2 C;

[0029] (2) High-pressure supercritical fluid CO containing dissolved sodium dehydroacetate 2 B is reduced to a pressure lower than the supercritical fluid CO through the throttle valve D 2 Enter the separation tank F below the critical pressure; supercritical fluid CO 2 The solubility drops sharply and the solute is precipitated, which is separated into two parts: sodium dehydroacetate solution H and supercritical fluid gas. The former is a process product, which is released from the bottom of the separation tank F regularly, and the latter is a circulating g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com