Method for preparing soda-lime glass from raw material alkali residue byproduct produced during firing of low-modulus water glass with coal gangue acid-leached residue-sodium sulfate

A soda lime glass and acid leaching slag technology, applied in silicate, alkali metal silicate and other directions, can solve the problems of environmental pollution, difficult to reuse, affect the pH value of soil layer, etc., to reduce energy consumption, reduce silicic acid The effect of calcification energy saving and lime decomposition energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

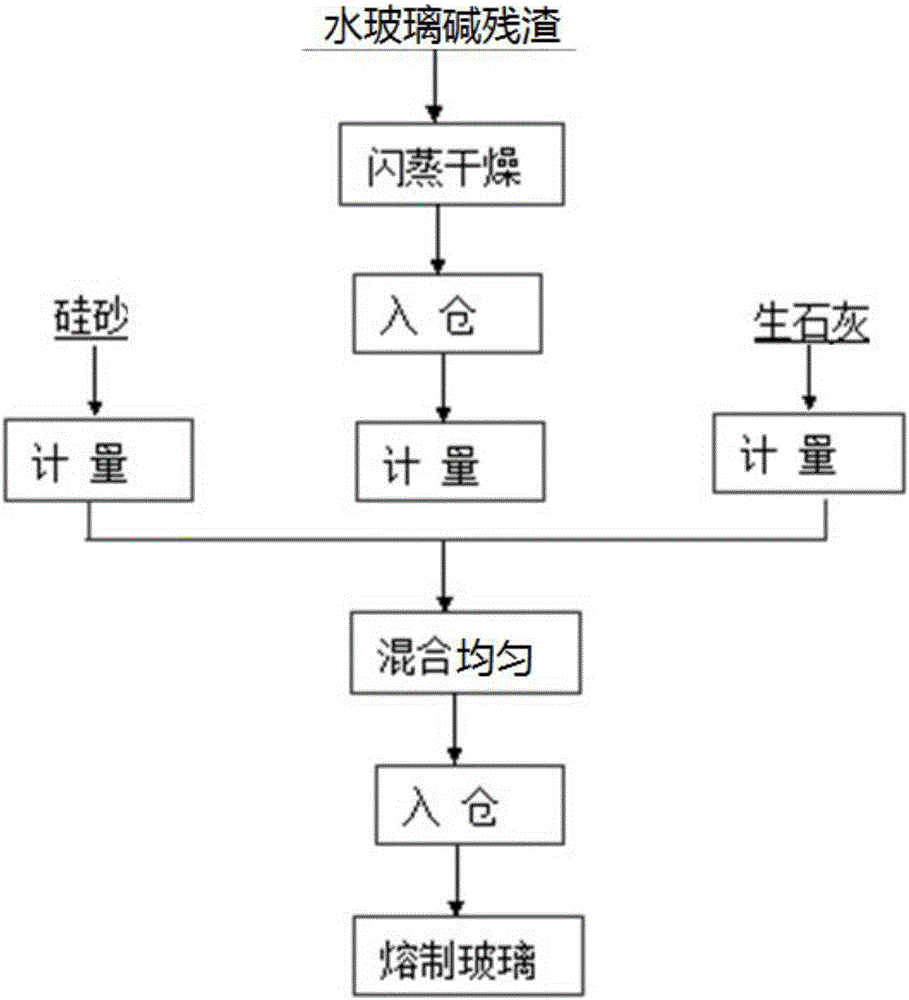

[0025] Such as figure 1 As shown, a method for preparing soda-lime glass with coal gangue acid leaching residue-sodium sulfate firing low-modulus sodium sulfate byproduct alkali residue as raw material, will use coal gangue acid leaching residue by-product sodium sulfate firing low modulus The alkali residue produced by water glass is dried by a flash dryer, and its composition is analyzed. The result is that it contains 48.8% of silicon dioxide, 31.88% of sodium oxide, 15.25% of calcium oxide, and the content of aluminum oxide is 2.35%. %, the content of magnesium oxide is 0.80%, the content of ferric oxide is 0.41%, the content of potassium oxide is 0.53%, and others. After it is stored in the warehouse, it is ready for use;

[0026] Get above-mentioned alkali residue 110kg, take by weighing siliceous sand 85kg, unslaked lime 0kg, after it is mixed uniformly, obtain mixture; And carry out component analysis to mixture, wherein contain silicon dioxide 72.32%, sodium oxide 15...

Embodiment 2

[0030] Such as figure 1 As shown, a method for preparing soda-lime glass with coal gangue acid leaching residue-sodium sulfate firing low-modulus sodium sulfate byproduct alkali residue as raw material, will use coal gangue acid leaching residue by-product sodium sulfate firing low modulus After the alkali residue produced by water glass is dried by a flash dryer, it is subjected to component analysis, and the result is that it contains 48.9% of silicon dioxide, 30.22% of sodium oxide, 16.68% of calcium oxide, and the content of aluminum oxide is 2.35%. %, the content of magnesium oxide is 0.81%, the content of ferric oxide is 0.46%, the content of potassium oxide is 0.65%, and others. After it is stored in the warehouse, it is ready for use;

[0031] Take 100kg of the above-mentioned alkali residue, weigh 95kg of silica sand, and 0-4 parts of quicklime, and mix them uniformly to obtain a mixture; and analyze the composition of the mixture, which contains 71.90% of silicon di...

Embodiment 3

[0035] Such as figure 1 shown, as figure 1As shown, a method for preparing soda-lime glass with coal gangue acid leaching residue-sodium sulfate firing low modulus water glass by-product alkali residue as raw material, will use coal gangue acid leaching residue by-product sodium sulfate firing low modulus After the alkali residue produced by water glass is dried by a flash dryer, it is subjected to component analysis, and the result is that it contains 49% of silicon dioxide, 29.22% of sodium oxide, 17.68% of calcium oxide, and the content of aluminum oxide is 1.35%. %, the content of magnesium oxide is 0.81%, the content of ferric oxide is 0.46%, the content of potassium oxide is 0.65%, and others. After it is stored in the warehouse, it is ready for use;

[0036] Take 100kg of the above-mentioned alkali residue, weigh 95kg of silica sand, and 0-4 parts of quicklime, and mix them uniformly to obtain a mixture; and analyze the composition of the mixture, which contains 71.90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com