Combined treatment process for non-biodegradable organic wastewater

A technology for organic waste water and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of improving biodegradability, wide application range and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

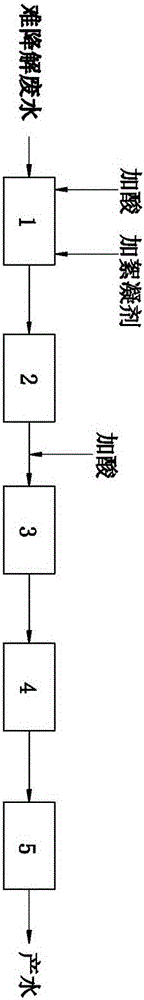

[0029] as attached figure 1 Shown, a kind of combined treatment process of refractory organic waste water, comprises the following steps:

[0030] (1) Coagulation and sedimentation: the sewage enters the sedimentation tank 1, adjusts the pH to 6-7 by adding acid, adds flocculant to make coagulation and sedimentation, and the supernatant is sent to the coarse filter 2;

[0031] (2) Coarse filtration: the sewage is filtered through the multi-layer sieve tube in the coarse filtration filter 2, and after the high-efficiency mud-water separation, the effluent enters the next process;

[0032] (3) Internal electrolysis reaction: After adding acid, the coarse filtered water is adjusted to pH 2-5, and then sent to the double internal electrolysis reactor 3, which is filled with integrated filler 31 containing iron, copper and carbon, and the waste water In the reactor, the principle of iron-copper and iron-carbon primary batteries is used to treat wastewater based on the joint action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com