Piece cargo assembly device

A container and cargo technology, applied in the field of turnover devices, can solve the problems of high labor intensity, inability to automatically tighten, and high labor intensity, and achieve high bundling efficiency, convenient and fast locking and unlocking, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

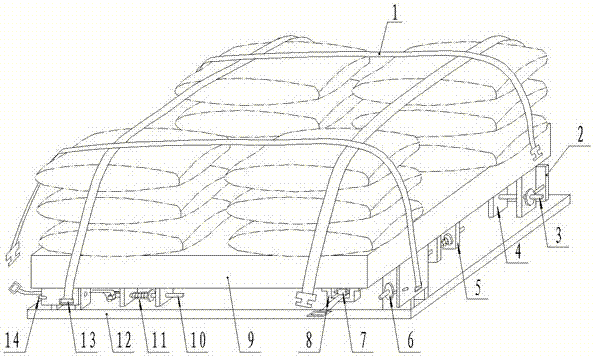

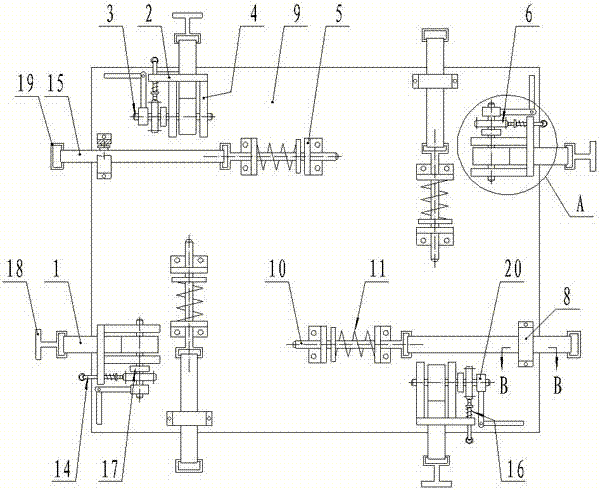

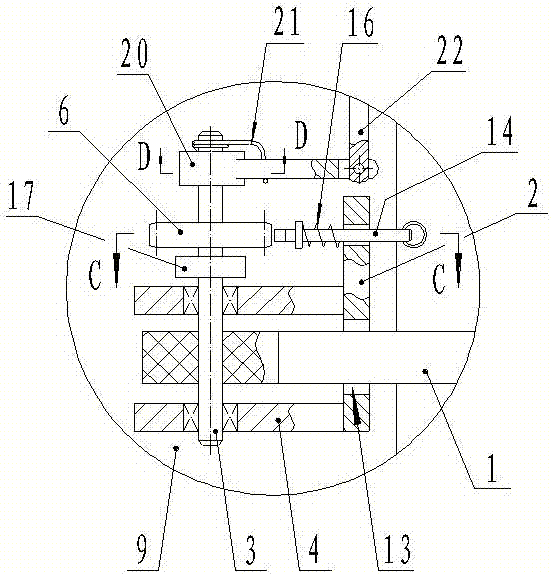

[0019] Such as Figure 1~6 As shown: the base 9 is in the shape of a rectangular plate, and the back of the base near the four corners has fastening belt storage devices respectively. This fastening belt storage device is fixed on the first bracket 4 fixed on the base 9, the baffle plate 2 with the window 13 fixed on the first bracket, the take-up shaft 3 supported on the first bracket 4, and fixed on the first bracket 4. The first ratchet 6 on the take-up shaft, the first pawl 14 that passes through the baffle plate 2 and engages with the first ratchet, and the first spring 16 that is arranged on the first pawl are formed, and each take-up shaft 3 is coiled There is a first fastening strap 1 whose end passes through the window 13 and protrudes to the outside of the base 9 . The first bracket 4 can also play a role in supporting the base 9, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com