Fire hose binding device

A fire hose and hose technology, applied in fire rescue and other directions, can solve the problems of separation of hose and interface, delaying fire supply water supply, injury accidents, etc., and achieve the effect of easy operation, good effect and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

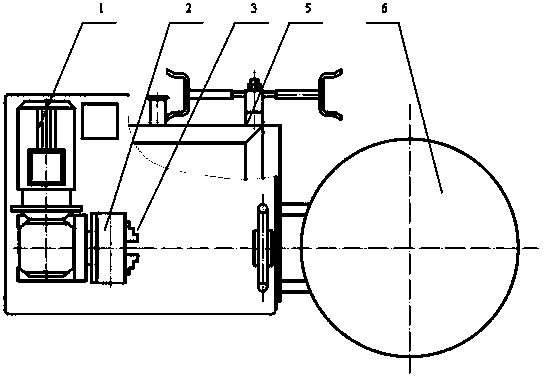

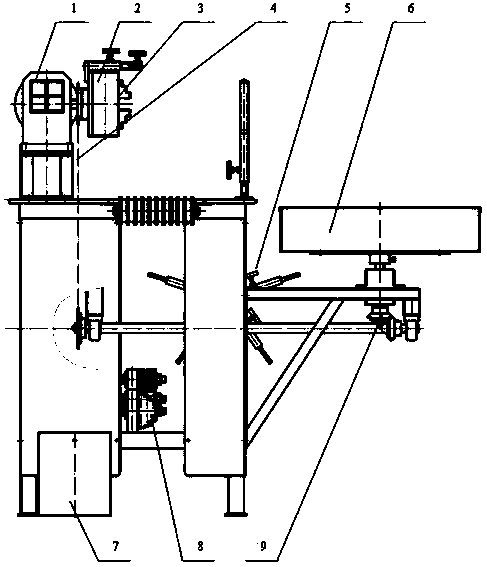

[0017] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] A fire hose lashing device, on the top of the workbench, driven by the output shaft in the horizontal direction of the motor 1, connected to the lashing runner 2, and the other side of the lashing runner 2 is provided with a multi-jaw chuck type hose interface fixer 3 ;

[0019] The horizontal output shaft of the motor 1 is connected to the horizontal long rotating shaft arranged at the lower part of the workbench through the chain 4 or the belt transmission, and the top of the long rotating shaft is provided with a reversing gear 9, and the reversing gear 9 meshes with a vertically configured hose reel 6. The tape reel 6 is disc-shaped and rotates in a horizontal direction;

[0020] A freely rotatable wire binding reel 5 is arranged on the side of the workbench;

[0021] In the lower part of the binding wheel 2, between the binding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com