Bead ring compound piece and tire rim structure with same

A technology of bead rings and composite parts, applied in tire parts, tire rims, vehicle parts, etc., can solve the problems of reduced carcass strength, too little rubber, carcass damage, etc., to prevent moisture and moisture from eroding steel wires ring, ensuring support rigidity, and suppressing the effect of radial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

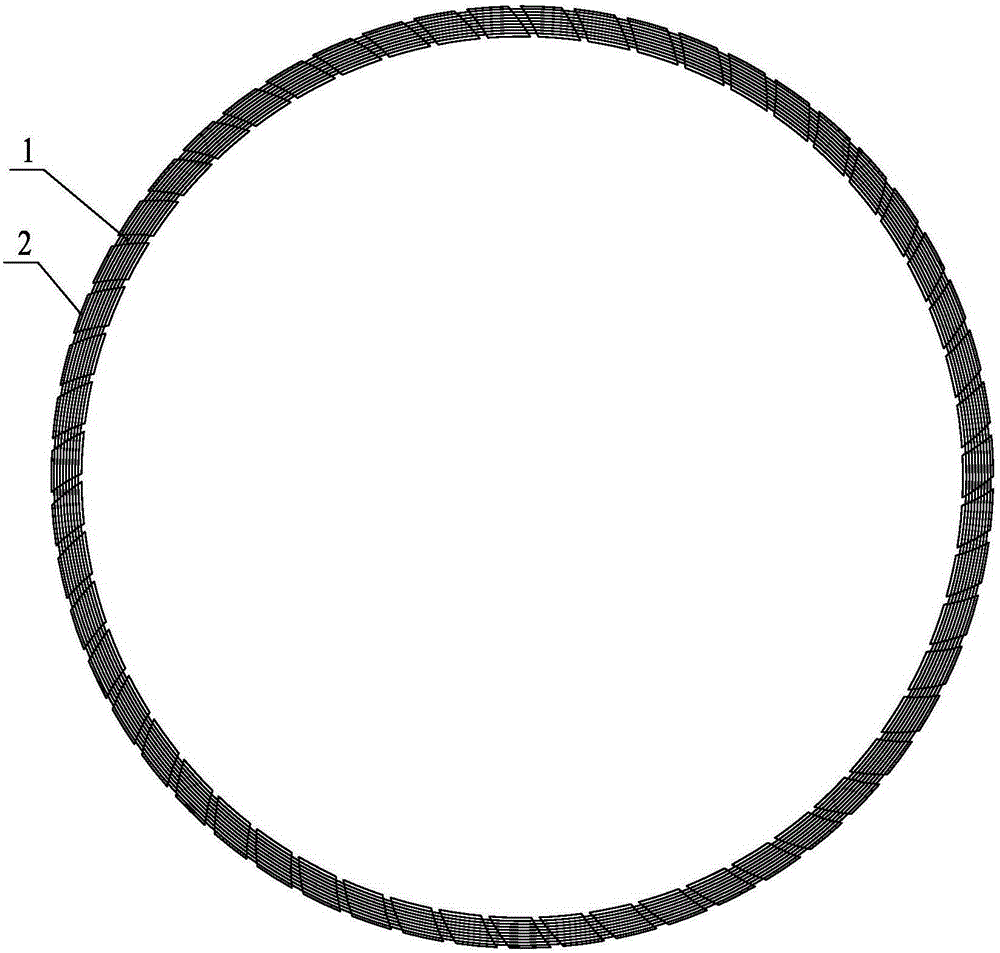

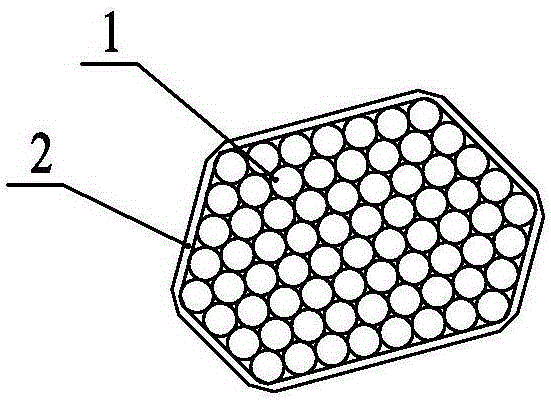

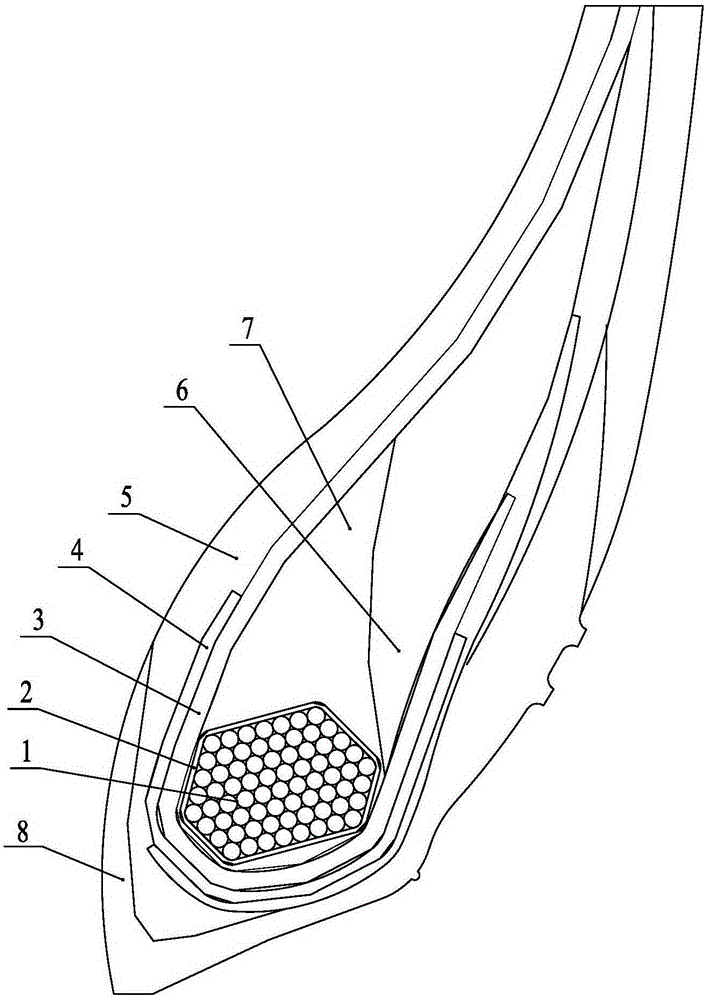

[0020] figure 1 , figure 2 The middle one is a traveler composite part, which includes a traveler 1, and a high thermal expansion composite rubber strip 2 is wound around the traveler 1, and the high thermal expansion composite rubber strip 2 is spirally and non-overlapped and evenly wound on the traveler 1 On the outside, the winding angle of the high thermal expansion composite rubber strip 2 on the traveler 1 is 30-45°, and the winding gap is 0-2 mm.

[0021] In the present invention, the high thermal expansion composite rubber strip 2 is refined from a high thermal expansion compound rubber material, and the high thermal expansion compound rubber material is made by adding high thermal expansion polyethylene resin and rubber through rubber-plastic mixing. forged. The high thermal expansion composite rubber strip 2 has the following characteristics: 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com