Bilateral longitudinal sectioning slicer for bamboo products

A technology of bamboo products and slicers, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of low transmission efficiency and inconvenient collection, and achieve the effects of reducing production costs, avoiding waste, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

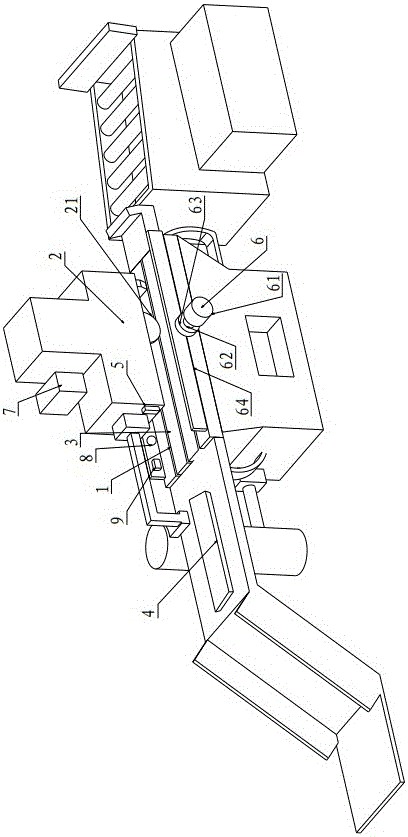

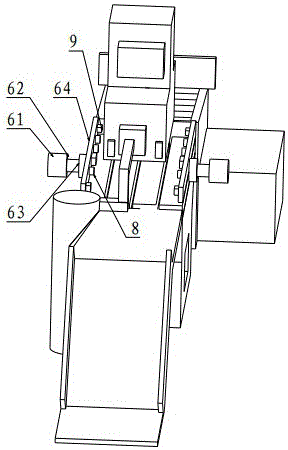

[0019] Such as figure 1 As shown, the bilateral longitudinal sectioning machine for bamboo products includes a working table 1, a cutting device 2 and a conveyor belt 3, the conveyor belt 3 is placed at the center of the working table 1, and the cutting device 2 includes two At least two blades 21 on the side; the slicer also includes two infrared positioning devices 5 and two automatic pushing devices 6, a programmable logic controller 7, at least two displacement sensors 8; two infrared positioning devices 5 are placed in the cutting on the device 2, and each infrared positioning device 5 locates the position of its longitudinal cutting edge on the bamboo product 4; at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com