InFocus electric arc synchronous welding method for two sides of T-shaped connector

A welding method and arc welding technology, applied in arc welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of high cost of laser synchronous welding, low joint strength, large welding deformation, etc., and achieve interchangeability of consumables Good performance, improved welding quality, and reduced equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

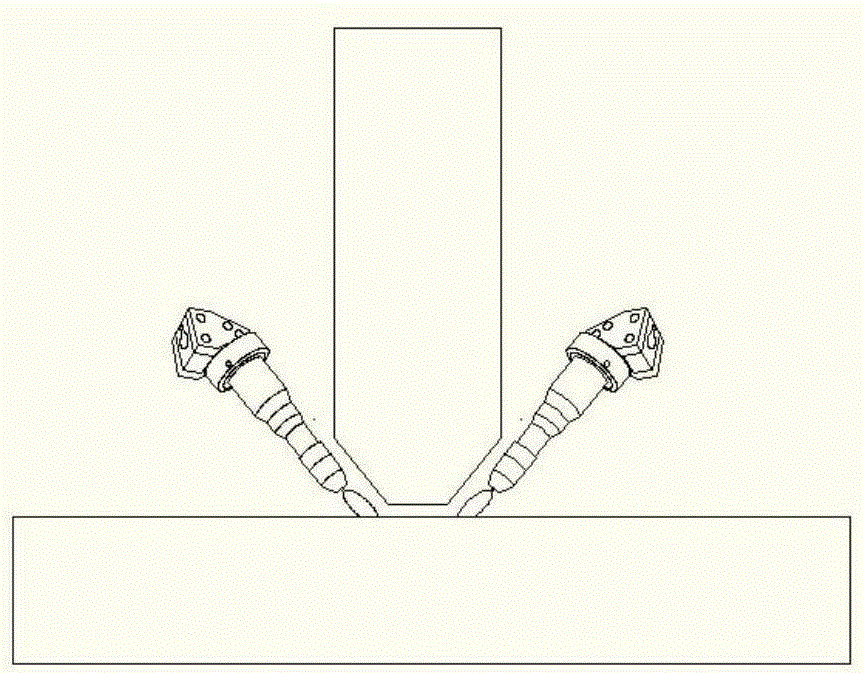

[0027] Specific embodiment one: a kind of T-joint bilateral InFocus arc synchronous welding method of the present embodiment, it is carried out according to the following steps:

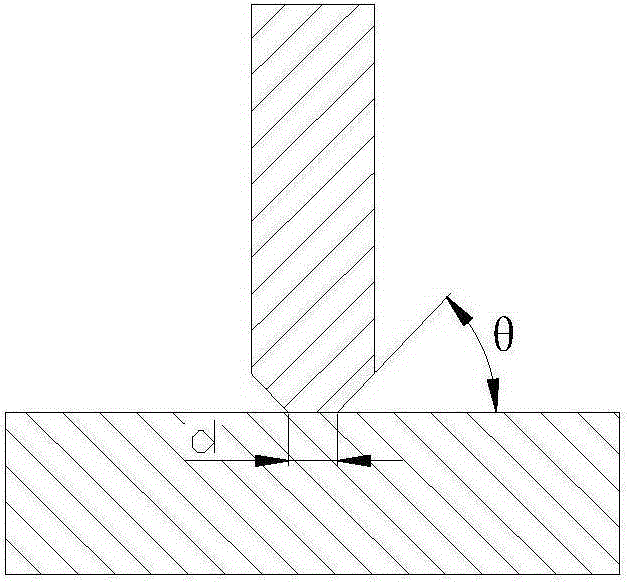

[0028] Step 1: Process the part of the workpiece to be welded into a groove or not. Before welding, grind the double-sided symmetrical welding groove and the surface within 30mm of the two sides, and then clean the groove and both sides of the groove with acetone. side surface;

[0029] Step 2: the workpiece is fixed on the fixture to be welded;

[0030] Step 3: Keep the included angle between the InFocus welding torch and the longitudinal surface of the T-shaped joint panel as α, where α is 30° to 45°, and the included angle β with the T-shaped bottom plate is 30°;

[0031] Step 4: Set the process parameters. In the InFocus arc synchronous welding on both sides of the T-joint, the welding current is 300A~900A; the gas flow rate of the arc welding torch is 15L / min~30L / min; the welding speed is 0.6m / ...

specific Embodiment approach 2

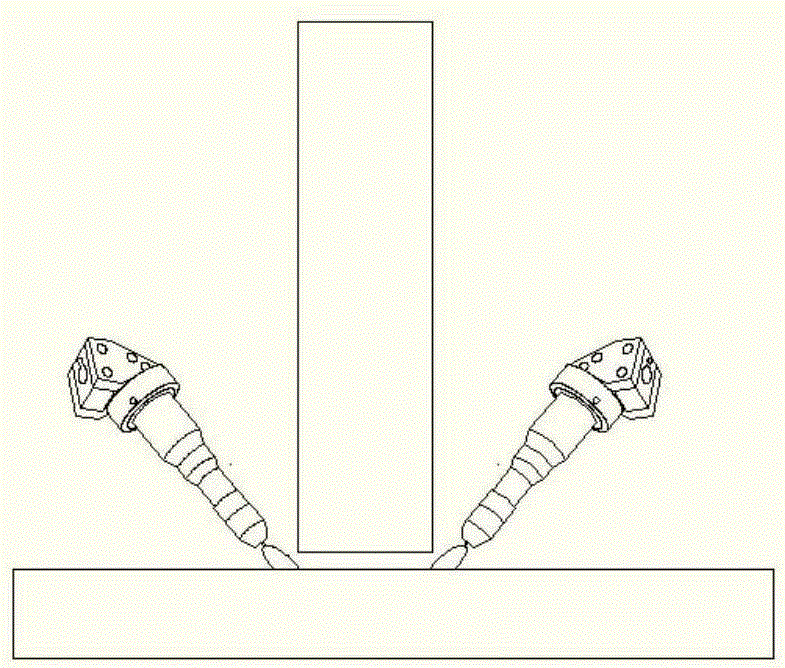

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that the welding is carried out along the normal direction of the transverse surface of the T-shaped joint panel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 in that: the InFocus arc synchronous welding on both sides of the T-shaped joint means that two InFocus welding torches are symmetrically distributed on both sides of the T-shaped joint and welded simultaneously. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com