Preparation process of pm2.5 dual-purpose dust protective mask

A protective mask and preparation technology, which is applied in the field of occupational hygiene products, can solve problems such as poor face adaptability, affecting the enthusiasm of workers to wear personal dust-proof products, and feeling uncomfortable, so as to reduce the cost of single use, good dust protection effect, The effect of individual suitability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

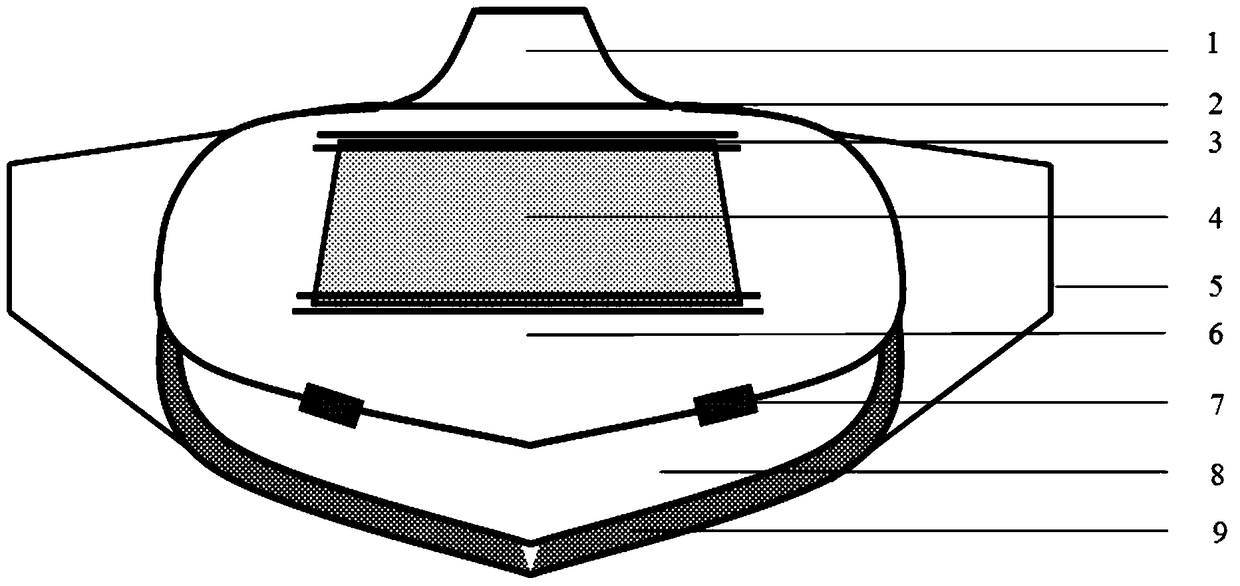

[0060] Push-type individual dust protection mask, such as figure 1 As shown, it includes the nose bracket 1, the drawing groove I2, the outer cover rotating shaft 3, the dust-proof filter film I4, the hanging ear or the safety helmet connector I5, the outer cover 6, the sealing buckle 7, the bottom frame 8 and the sealing layer 9. The outer edges of the inner side of the nose bracket 1 and the bottom frame 8 are both rough and protruding structures; the outer cover rotating shaft 3 is a cylindrical shaft and is arranged inside the outer cover 6; the drawing groove I2 is welded to the outer cover 6; the dust-proof filter membrane I4 is arranged in the drawing groove I2; the sealing layer 9 is evenly arranged in the edge position of the nose bracket 1 and the bottom frame 8 in a strip shape; the sealing buckle 7 is fixedly arranged outside Cover 6; the hanging ear or safety helmet connector I5 is fixedly connected to the outer edge of the chassis 8; the position covered by the out...

Embodiment 2

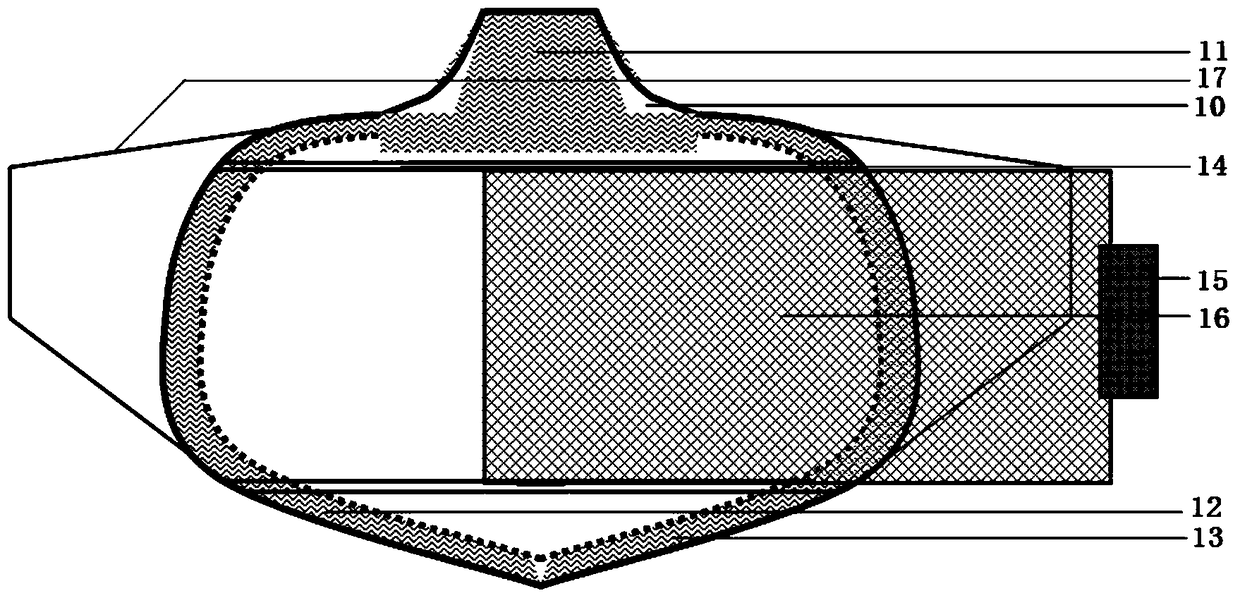

[0080] Pull-out personal dust protective mask, such as figure 2 As shown, it includes the outer support sheet 10, the inner nose sealing layer 11, the right face inner sealing layer 12, the left face inner sealing layer 13, the drawing groove II 14, the drawing handle 15, the dust blocking filter film II 16 and the hanging ear Or helmet connector II 17, the outer support sheet 10 is connected to the inner nose seal layer 11, the right face inner seal layer 12, and the left face inner seal layer 13, respectively; the outer support sheet 10 is provided with two pulls 1-50 holes are arranged between the two drawing grooves II14; the dust blocking filter membrane II16 is arranged in the drawing groove II14; the drawing handle 15 and the outside of the dust blocking filter membrane II16 The short side of the support frame is connected; the drawing groove II14, the hanging ear or the helmet connecting piece II17 are fixedly connected with the outer support sheet 10.

[0081] The pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com