A kind of porous tantalum metal hollow screw and its application

A hollow screw, porous tantalum technology, applied in medical science, internal bone synthesis, fastening devices, etc., can solve the problems of weak biomechanical performance, internal fixation screw fracture, fracture re-displacement, etc. Clinical application, pain relief, high histocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

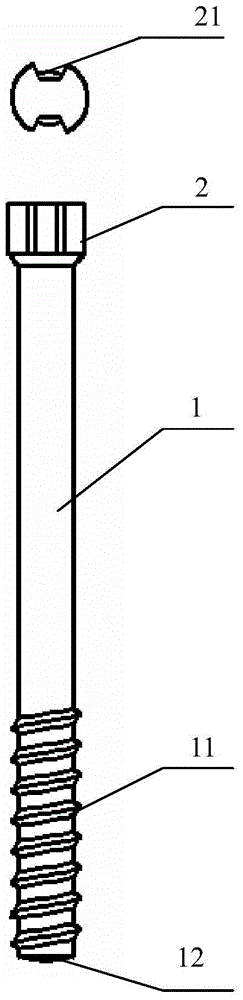

[0036] Such as figure 1 As shown, a hollow screw made of porous tantalum metal comprises a screw 1 and a nut 2, the screw 1 and the nut 2 are integrally formed, the outer surface of the front section of the screw 1 has a thread 11, and the length of the thread 11 is The length ratio of the screw 1 is 1:2, the nut 2 is a conical nut with a cylindrical nail head, the angle between the conical surface of the conical nut and the centerline of the screw is 45°, and the cylindrical The two side outer surfaces of the shaped nail head are symmetrically provided with grooves 21 with the center line of the screw rod, and the angle between the two slopes of the groove 21 is 60°. And between the nut 2 is a smooth slide bar.

[0037] in:

[0038] The pitch of the thread 11 is 4mm, the width of the thread 11 is 2mm, the difference between the outer diameter and the inner diameter of the thread 11 is 10% of the diameter of the screw rod 1, and the lead angle of the thread 11 is 91°; 11 is...

Embodiment 2

[0047] The porous tantalum metal hollow screw described in Example 1 is prepared by the following method:

[0048] (1) The graphite carbon skeleton with a porosity of 85% was etched with dilute hydrochloric acid for 10 minutes, washed with water and ethanol in turn, dried with nitrogen, and placed in the reaction chamber;

[0049] (2) Put the carbon pentachloride powder with a particle size of 400 mesh into the source tank, heat it to 150°C, and use high-temperature argon (300°C) as the carrier gas to pass into the reaction chamber, and the flow rate of the carrier gas is 100ml / min , the temperature of the reaction chamber is 1050°C, and the vacuum degree of the reaction chamber is 10Pa; while the tantalum pentachloride powder is passed into the reaction chamber with argon as the carrier gas, hydrogen is passed into the reaction chamber at a flow rate of 120ml / min, and the reduction reaction is carried out for 4 hours. The tantalum metal reduced to metal powder is evenly depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com