A kind of pure papermaking method reconstituted tobacco leaf cigarette

A technology for reconstituting tobacco leaves and making paper, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of high requirements on whiteness and opacity, poor taste, and bad taste of cigarettes, and achieves obvious effects of reducing harm and reducing coke. , the production cost is low, the effect of cigarette smoking is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

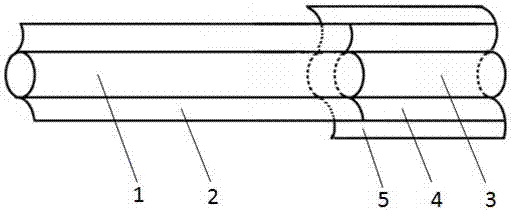

Embodiment 1

[0023] Take a certain amount of paper-making reconstituted tobacco leaves and cut them into paper-making reconstituted tobacco shreds with a shredding machine; 49 parts of tobacco stems, 35 parts of calcium carbonate, 15 parts of wood pulp and 1 part of sodium citrate are produced by paper-making reconstituted tobacco leaves Processed to quantitative 30 ~ 50g / m 2 , Paper-making reconstituted tobacco leaf cigarette paper with longitudinal tensile strength ≥ 0.95kN / m; another certain amount of paper-making reconstituted tobacco leaves, after being wrinkled, cut into crumpled paper-making reconstituted tobacco shreds; 60 parts of tobacco stems , 15 parts of calcium carbonate and 25 parts of wood pulp fiber are processed into a quantitative 30-60g / m by the papermaking process of reconstituted tobacco leaves 2 , Longitudinal tensile strength ≥ 0.90kN / m paper-making reconstituted tobacco forming paper; 50 parts of tobacco stems, 15 parts of calcium carbonate and 35 parts of wood pul...

Embodiment 2

[0025] Take a certain amount of paper-making reconstituted tobacco leaves, cut them into paper-making reconstituted tobacco shreds with a shredder; use 64 parts of tobacco stems, 25 parts of calcium carbonate, 10 parts of wood pulp and 1 part of sodium citrate to reconstitute tobacco leaves with paper-making methods The production process is processed into a quantitative 30~50g / m 2 , Paper-making reconstituted tobacco leaf cigarette paper with longitudinal tensile strength ≥ 0.95kN / m; another certain amount of paper-making reconstituted tobacco leaves, after being wrinkled, cut into crumpled paper-making reconstituted tobacco shreds; 75 parts of tobacco stems , 10 parts of calcium carbonate and 15 parts of wood pulp fiber are processed into a quantitative 30-60g / m by the reconstituted tobacco leaf production process of the papermaking method 2 , Longitudinal tensile strength ≥ 0.90kN / m paper-making reconstituted tobacco forming paper; 65 parts of tobacco stems, 15 parts of cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com