Inner layer bonding pad later-windowed rigid-flexible printed circuit board and manufacturing method thereof

A technology of soft and hard combination board and inner layer, which is applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of reduced yield rate, low yield rate, increased production cost, etc., and achieve high efficiency and high yield rate High and yield-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

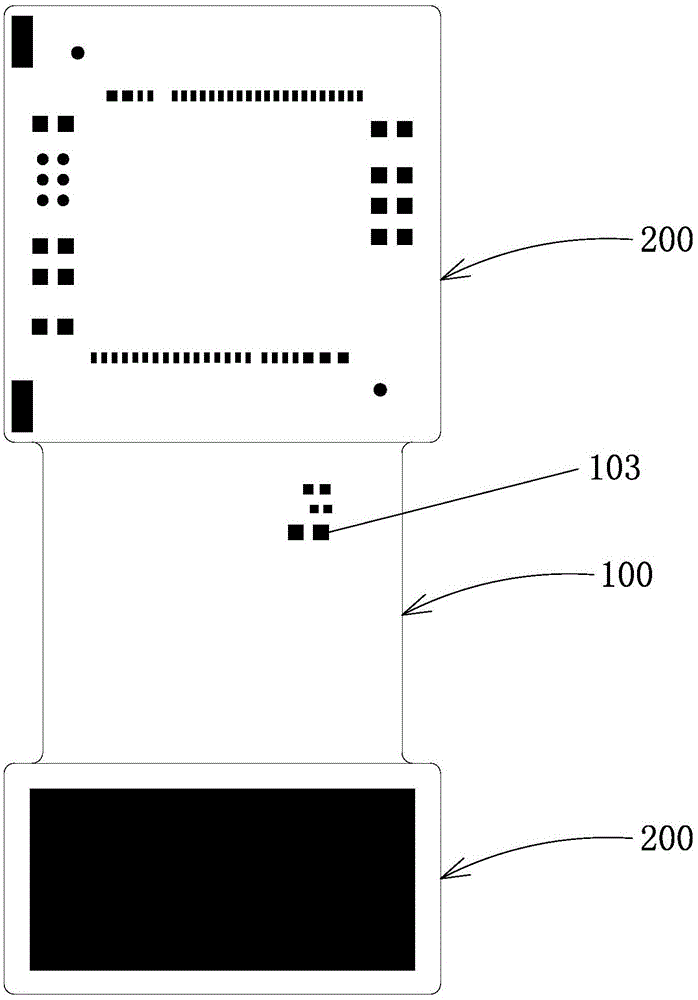

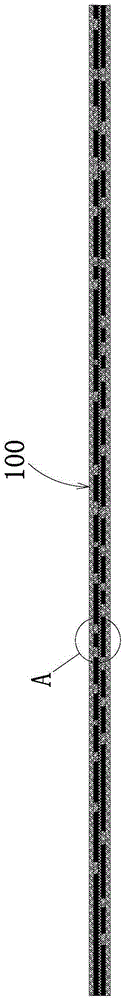

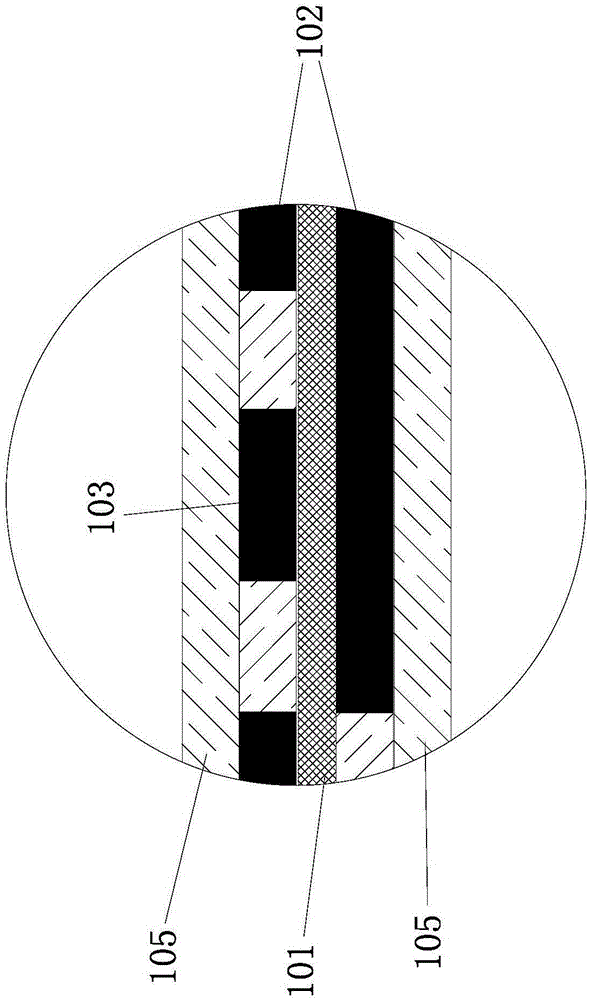

[0031] The invention provides a method for manufacturing a rigid-flex board with a rear opening of an inner pad, comprising the following steps:

[0032] S1. FPC base material 101 is cut, drilled, and copper-plated. According to the circuit design requirements, the FPC copper layer 102 of the FPC base material 101 is etched to form an inner layer circuit, and at the same time, the window area 104 is etched according to the window opening requirements. For the corresponding inner layer pad 103, when etching to form the inner layer pad 103, it should be ensured that the window area 104 can fall within the range of the corresponding inner layer pad 103, and the inner layer cover film 105 without a window should be attached to the corresponding inner layer pad 103. The surface of the flexible board substrate 101 described above. In this step, the windowed area 104 of the inner covering film 105 is not pierced temporarily and passes through CO in a later step. 2 laser burn through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com