LC filtering system, LC filtering circuit, electronic circuit and device

A filter circuit and capacitor technology, applied in the field of electricity, can solve the problems that signal filtering cannot be used, high-voltage circuit filtering cannot be used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

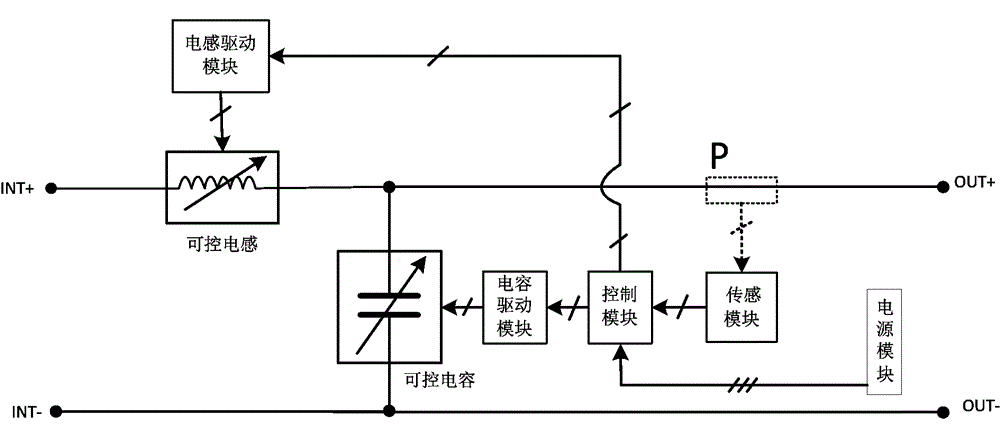

[0068] Implementation example 1, such as figure 1 As shown, the LC filter system is characterized in that it includes a first input node INT+, a second input node INT-, a first output node INT+, a second output node INT-, a capacitor drive module, a controllable capacitor, an inductance drive module, Controllable inductance, control module, sensing module, sampling point P, power module;

[0069] One functional terminal of the controllable inductor is connected to the first input node INT+, and the other functional terminal of the controllable inductor is electrically connected to the first output node OUT+;

[0070] There is an electrical connection between one functional terminal of the controllable capacitor and the first output terminal OUT+, and an electrical connection between the other functional terminal of the controllable capacitor and the second output terminal OUT-;

[0071] There is an electrical connection for transmitting electric energy between the power suppl...

Embodiment 2

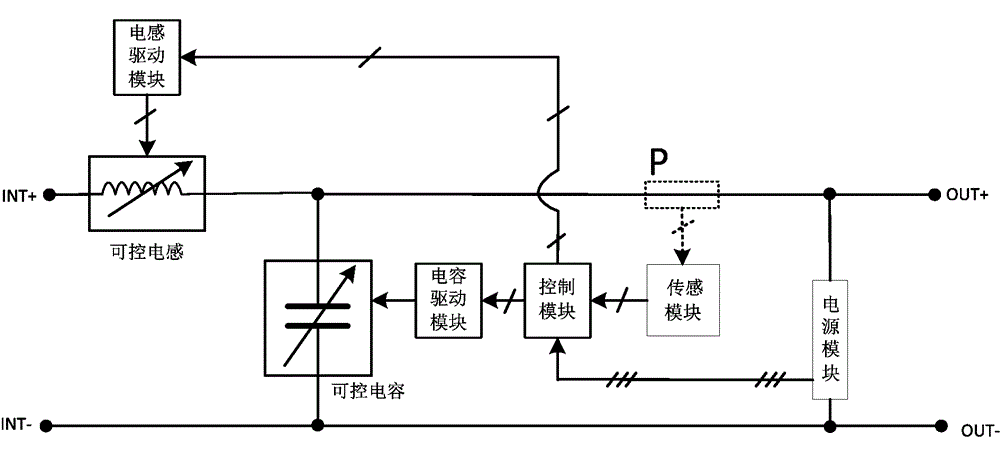

[0076] Implementation example 2, such as figure 2 As shown, based on the LC filter system described in Example 1, it is characterized in that: one input terminal of the power module is connected to the first output node OUT+ and the connection point is located on the electrical path between the sampling point P and the first output node OUT+ , the other input end of the power module is connected to the second output node OUT-.

Embodiment 3

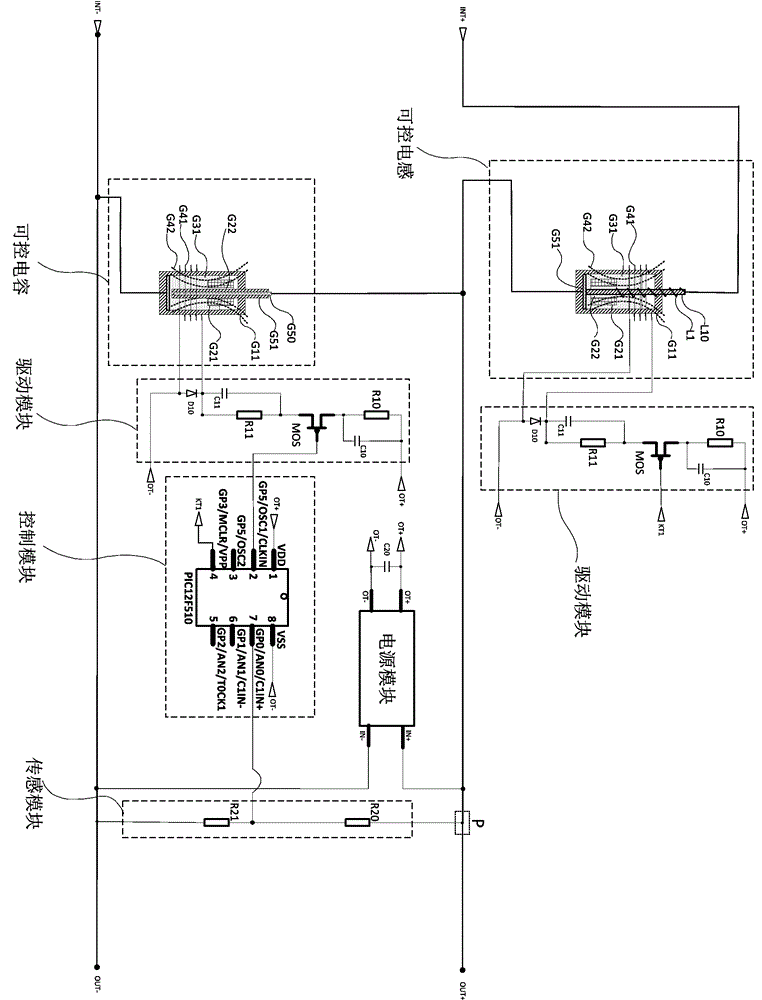

[0077] Implementation example 3, such as image 3 As shown, an LC filter circuit is characterized in that it includes a first input node INT+, a second input node INT-, a first output node INT+, a second output node INT-, a capacitor drive module, a controllable capacitor, and an inductance drive Module, controllable inductor, control module, sensor module, sampling point P, power module;

[0078] The characteristics of the controllable capacitor are as follows: including insulating container G11, conductive liquid G31, floating body G21, bottom electrode G51, capacitor rod G50, insulating layer G51, electromagnetic coil G41,

[0079] The insulating container G11 has a stable shape. The shape of the insulating container G11 is cylindrical. The container of the insulating container G11 is cylindrical. The cavity of the insulating container G11 is not easy to change in shape.

[0080] The conductive liquid G31 is contained in the cavity of the insulating container G11, the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com