A pendulum type eddy current tuned mass damper and method for realizing structural vibration reduction

A technology of tuning mass damping and eddy current, which is applied in the field of structural vibration reduction, can solve the problems that the stability and durability requirements of the damper cannot be met, the dynamic stability of the mass block is difficult to control, and the stability and durability of the damper are unfavorable. To achieve the effect of convenient later use and maintenance, guaranteed service life and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

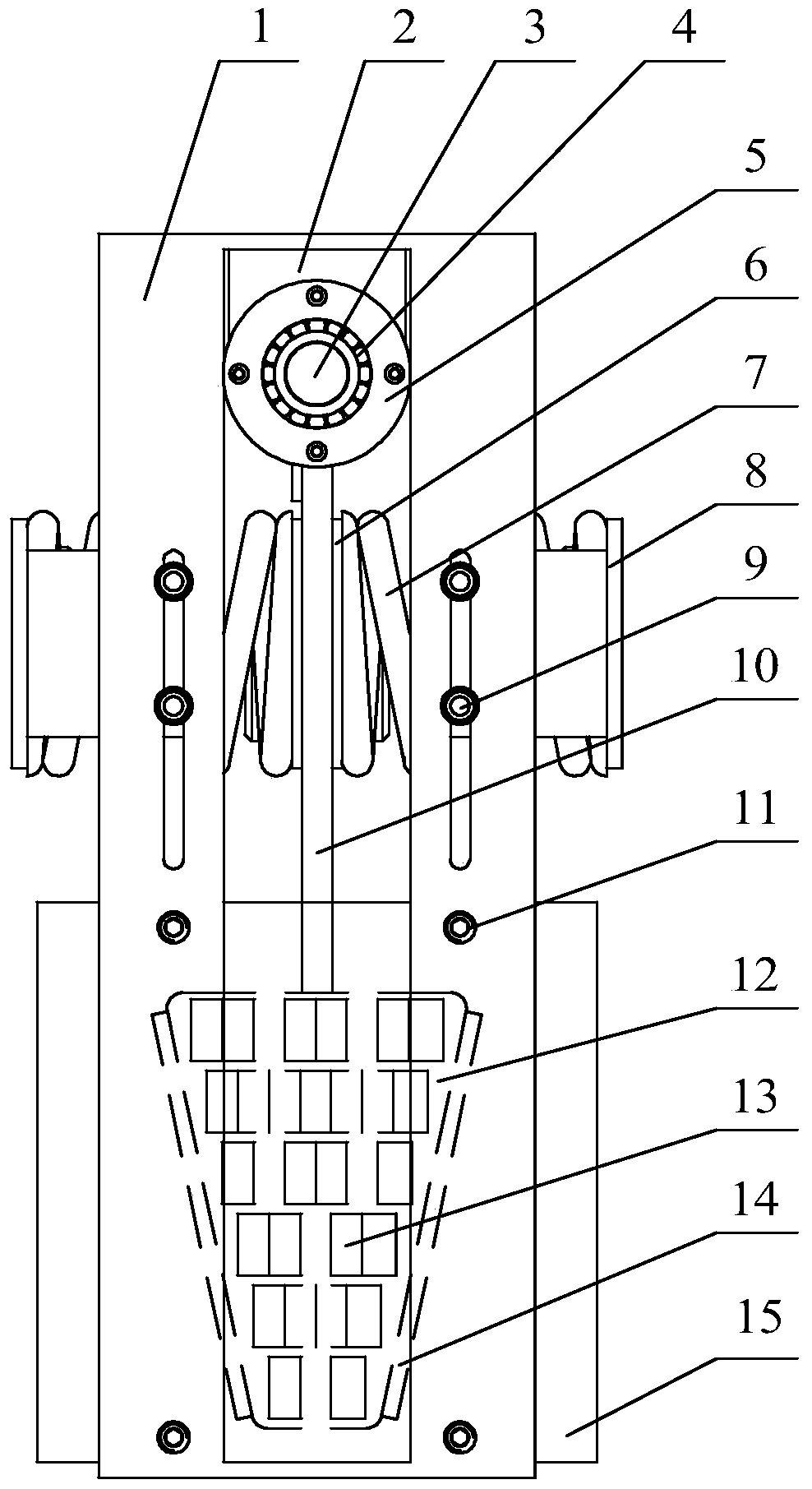

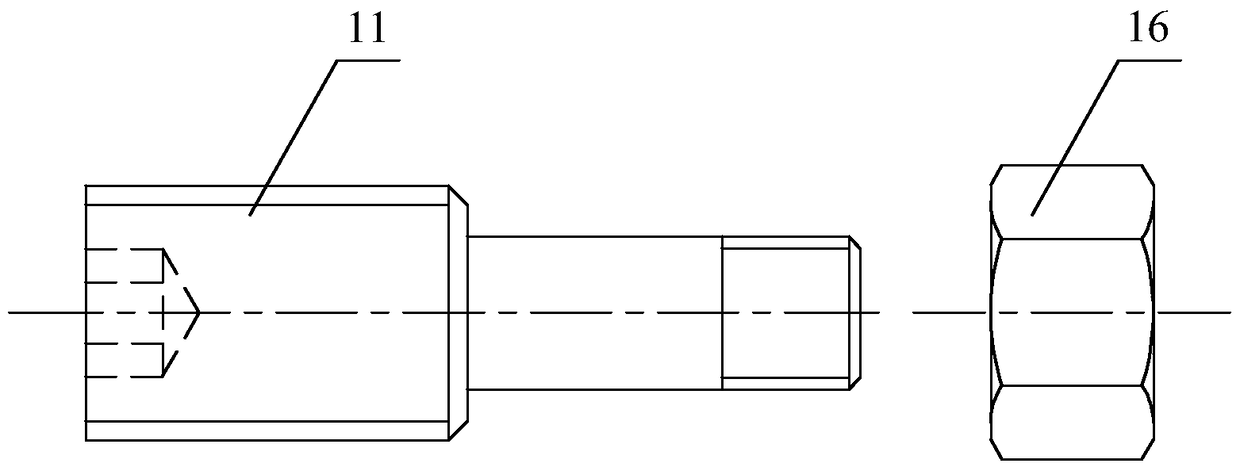

[0042] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a pendulum type eddy current tuned mass damper for structural vibration reduction, including a damper body, the damper body includes a bracket 1 with a cuboid structure, and the bracket 1 includes a front plate, a rear plate, and a top plate And the base plate, wherein, the bottom of the top plate is fixed with two bearings 4 (preferably deep groove ball bearings) parallel to the front plate and the rear plate through the fixed ear plate 2, and the end face of each bearing 4 is provided with a bearing end cover 5, The inner rings of the two bearings 4 are connected by a horizontally arranged rotating shaft 3, a swing rod 10 is vertically arranged below the rotating shaft 3, the top of the swing rod 10 is connected with the rotating shaft 3, and a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com