Directly-operated automatic water replenishing valve for solar water heater

A technology for solar water heaters and automatic water replenishment, applied to valve details, valve devices, engine components, etc., can solve the problems of poor appearance and reliability, complicated installation, high cost, etc., and achieve the effect of compact structure, convenient installation and transportation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

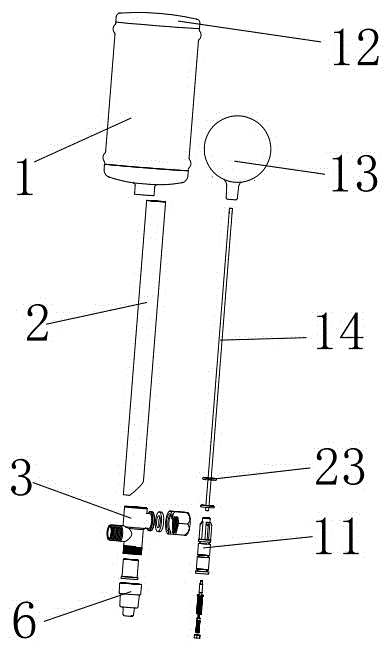

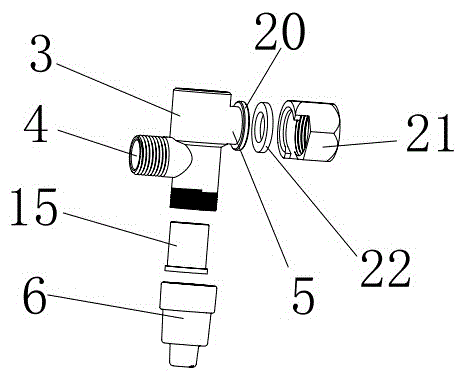

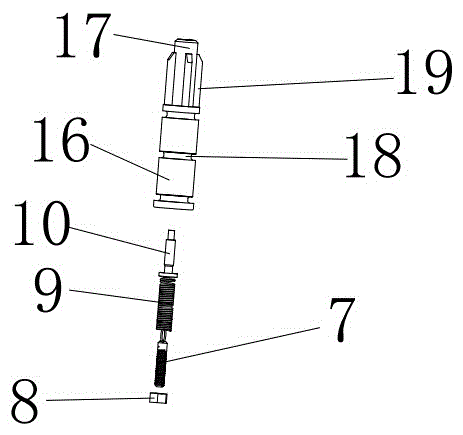

[0021] Such as figure 1 As shown, the direct-acting automatic replenishment valve for solar water heaters includes a floating bucket 1, a water level pipe 2 and a valve body 3; The wall is provided with an inlet pipe 4 and an outlet pipe 5. The inlet pipe 4 and the outlet pipe 5 are located on opposite sides of the valve body and are staggered up and down. The inlet pipe 4 is located below the outlet pipe 5; There is a round hole at the bottom of the sleeve 6, a screw rod 7 is installed in the round hole, an adjusting nut 8 is installed outside the screw rod 7 through the round hole, a cylindrical spring 9 is arranged above the screw rod 7, a screw 10 is arranged on the top of the cylindrical spring 9, and a valve is installed above the screw 10 The core 11, the side wall of the valve core 11 matches the shape of the inner cavity of the valve body 3; the water level pipe 2 is installed above the valve body 3, and the floating water bucket 1 is installed above the water level p...

Embodiment 2

[0024] Such as figure 1 As shown, the direct-acting automatic replenishment valve for solar water heaters includes a floating bucket 1, a water level pipe 2 and a valve body 3; The wall is provided with an inlet pipe 4 and an outlet pipe 5. The inlet pipe 4 and the outlet pipe 5 are located on opposite sides of the valve body and are staggered up and down. The inlet pipe 4 is located below the outlet pipe 5; The water pipe 5 is kept in communication with the water level pipe at any time, so that the water level pipe is consistent with the water level of the incubator, and the existing axial water inlet is changed to realize radial water inlet. The axial force of the valve core is independent of the water inlet pressure. The spool moves vertically and axially.

[0025] A fixed sleeve 6 is installed below the valve body 3, and there is a circular hole at the bottom of the fixed sleeve 6. A screw rod 7 is installed in the circular hole, and an adjusting nut is installed outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com