Chemical sand fixing agent application device and method

An applicator and sand-fixing agent technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems that rainwater cannot infiltrate smoothly to supplement deep soil moisture, seed vegetation recovery is unfavorable, and sandy soil respiration is restricted, etc., to achieve Improve wind erosion resistance, improve sand fixation effect, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

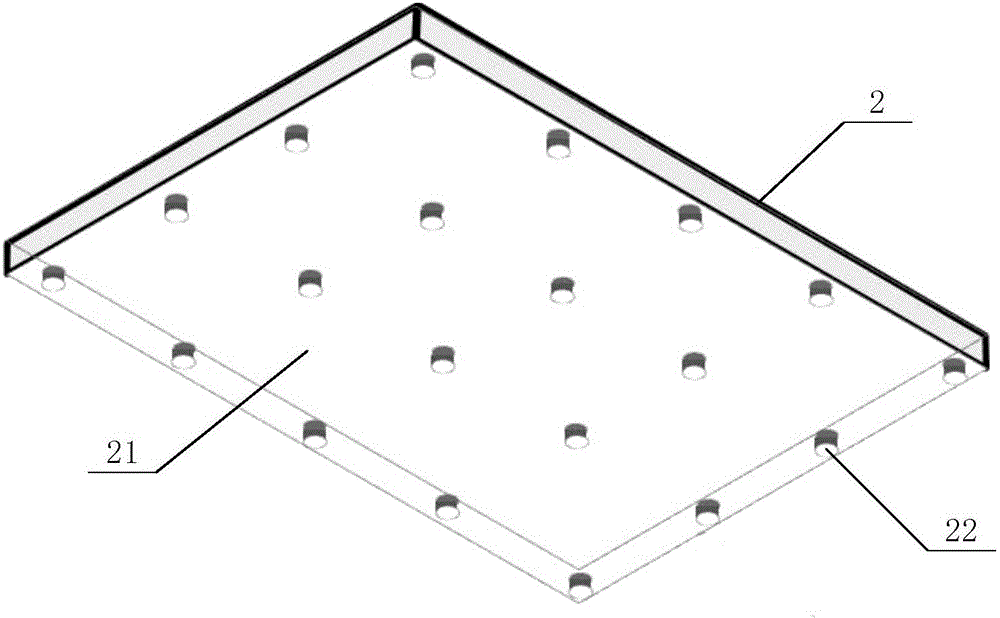

[0036] (1) if figure 1 and figure 2 As shown, the nozzle 1 preferably adopts an inverted cone with a vertical through hole 11 in the middle, and this inverted cone can prevent sand from entering the vertical through hole 11 to a certain extent. The chemical sand-fixing agent can be injected into the sand through the vertical through hole 11, and the bottom liquid outlet of the vertical through hole 11 is exactly the liquid outlet of the nozzle 1, so the aperture of the bottom liquid outlet of the vertical through hole 11 can be Choose flexibly according to different geological conditions and sand conditions, but the best range is 0.2-0.5mm.

[0037] In practical applications, the nozzle 1 is best made of high-strength stainless steel, which can not only improve the impact resistance of the nozzle 1, but also reduce the retention of sand and soil on the nozzle 1, which is easy to clean; even if sand and soil accidentally enter the vertical channel In the hole 11, it is also ...

Embodiment 1

[0072] Such as Figure 1 to Figure 11 As shown, the chemical sand-fixing agent is applied to a mobile sand dune using the above-mentioned chemical sand-fixing agent application method, and the specific steps are as follows:

[0073] (1) According to the geological conditions and sandy conditions of the mobile sand dunes, it is determined to select a nozzle 1 with a liquid outlet aperture of 0.2mm; according to the implementation density, it is determined that the nozzles 1 are arranged in a matrix of 4X3 at the bottom of the liquid separator 2, and two adjacent The distance between the nozzles 1 is 10cm; according to the above-mentioned structure, the components of the chemical sand-fixing agent applicator are assembled together, and the prepared chemical sand-fixing agent with a mass concentration of 10% is loaded into the liquid storage tank 4, and then dragged The load-bearing vehicle 7 moves the assembled chemical sand-fixing agent application device to the application sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com