An embedded track structure suitable for medium and small span bridges and its construction method

An embedded track and construction method technology, applied in the field of rail transit, can solve problems such as high construction requirements, slow construction progress, and large dead load in the second phase of the bridge, and achieve good vibration and noise reduction effects, increase overall stability, and reduce Effect of Structural Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

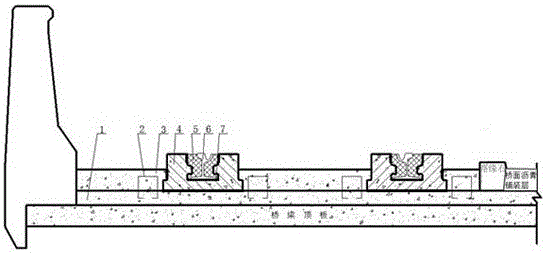

[0048] Such as figure 1 , 6 As shown, an embedded track structure suitable for medium and small-span bridges includes a bridge roof, a bridge deck cast-in-place layer 1, a connecting member 2, a reinforced concrete base 3, a bearing groove 4 and a grooved track 6, and the bridge deck is now The pouring layer 1 is poured on the bridge roof, and there are two grooved rails 6 and two rail bearing grooves 4, each of which is embedded in a rail bearing groove 4, and the two grooved rails The rail bearing grooves 4 are embedded in the reinforced concrete base 3 parallel to each other along the longitudinal direction, and the reinforced concrete base 3 is arranged on the cast-in-place layer 1 of the bridge deck and connects the cast-in-place layer 1 of the bridge deck with the reinforced concrete base 3 through the connecting member 2 into a whole.

[0049] Both sides of the lower part of the rail groove 4 protrude outward to form a "convex" structure.

[0050] The rail bearing gr...

Embodiment 2

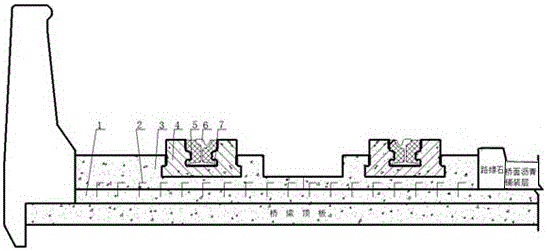

[0056] Such as figure 2 ,6 As shown, an embedded track structure suitable for medium and small-span bridges includes a bridge roof, a bridge deck cast-in-place layer 1, a connecting member 2, a reinforced concrete base 3, a bearing groove 4 and a grooved track 6, and the bridge deck is now The pouring layer 1 is poured on the bridge roof, and there are two grooved rails 6 and two rail bearing grooves 4, each of which is embedded in a rail bearing groove 4, and the two grooved rails The rail bearing grooves 4 are embedded in the reinforced concrete base 3 parallel to each other along the longitudinal direction, and the reinforced concrete base 3 is arranged on the cast-in-place layer 1 of the bridge deck and connects the cast-in-place layer 1 of the bridge deck with the reinforced concrete base 3 through the connecting member 2 into a whole.

[0057] Both sides of the lower part of the rail groove 4 protrude outward to form a "convex" structure.

[0058] The rail bearing gro...

Embodiment 3

[0064] Such as image 3 As shown, an embedded track structure suitable for medium and small-span bridges includes a bridge roof, a bridge deck cast-in-place layer 1, a connecting member 2, a reinforced concrete base 3, a bearing groove 4 and a grooved track 6, and the bridge deck is now The pouring layer 1 is poured on the bridge roof, and there are two grooved rails 6 and two rail bearing grooves 4, each of which is embedded in a rail bearing groove 4, and the two grooved rails The rail bearing grooves 4 are embedded in the reinforced concrete base 3 parallel to each other along the longitudinal direction, and the reinforced concrete base 3 is arranged on the cast-in-place layer 1 of the bridge deck and connects the cast-in-place layer 1 of the bridge deck with the reinforced concrete base 3 through the connecting member 2 into a whole.

[0065] The rail bearing groove 4 is a prefabricated concrete rail bearing groove.

[0066] The connecting member 2 is pre-embedded in bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com