Method for preparing ordered ion conductor based on polyelectrolyte brush

A polyelectrolyte brush and ion conductor technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as low ion conductivity, and achieve improved ion conductivity, improved brittleness, and regular and orderly structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing an ordered ion conductor based on a polyelectrolyte brush, comprising the following steps:

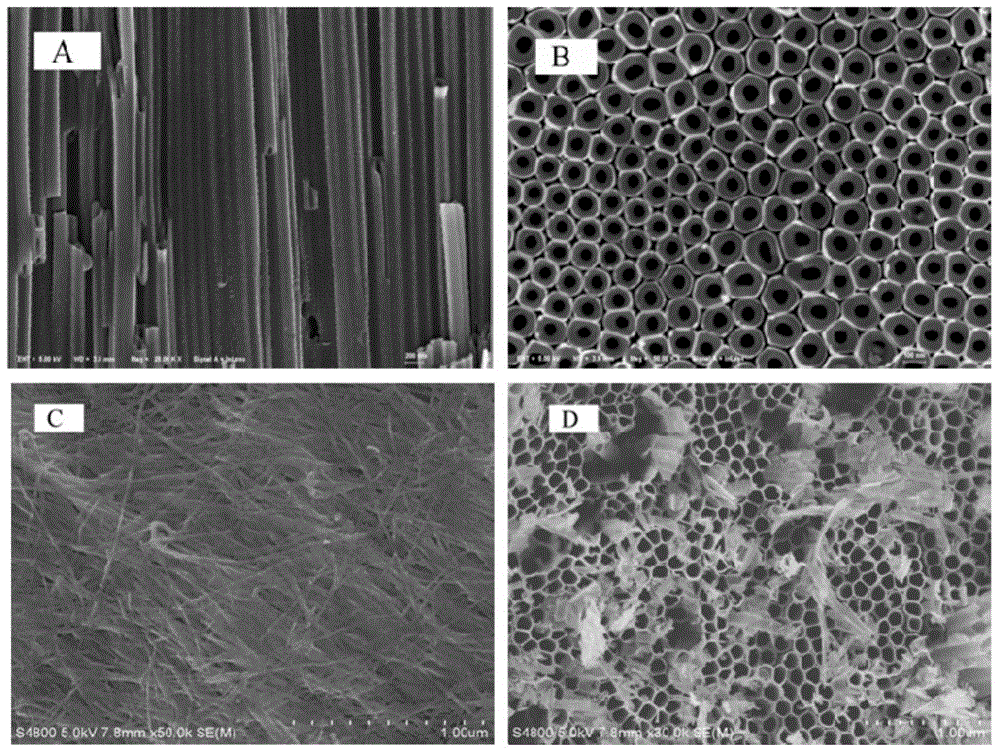

[0041] (1) Use detergent to clean the oil on the surface of the 1cm×1cm titanium sheet, then put it in ethanol, ultrasonicate for 10min, then wash it with deionized water, put it in acetone and ultrasonically for 10min, and then wash it with deionized water Wash and dry the washed titanium sheet; take the washed titanium sheet as the anode, and the metal platinum sheet as the cathode, and the titanium sheet and the platinum sheet have the same area immersed in the electrolyte, and are in a parallel and facing direction; The mixed solution of ammonium fluoride, water and ethylene glycol is the electrolyte, wherein the mass concentration of ammonium fluoride is 0.3wt%, the volume of water is 2vol%, and the rest is ethylene glycol; the power supply used in the anodic oxidation process is constant Piezoelectric power supply, the voltage is 60V; the oxidation t...

Embodiment 2

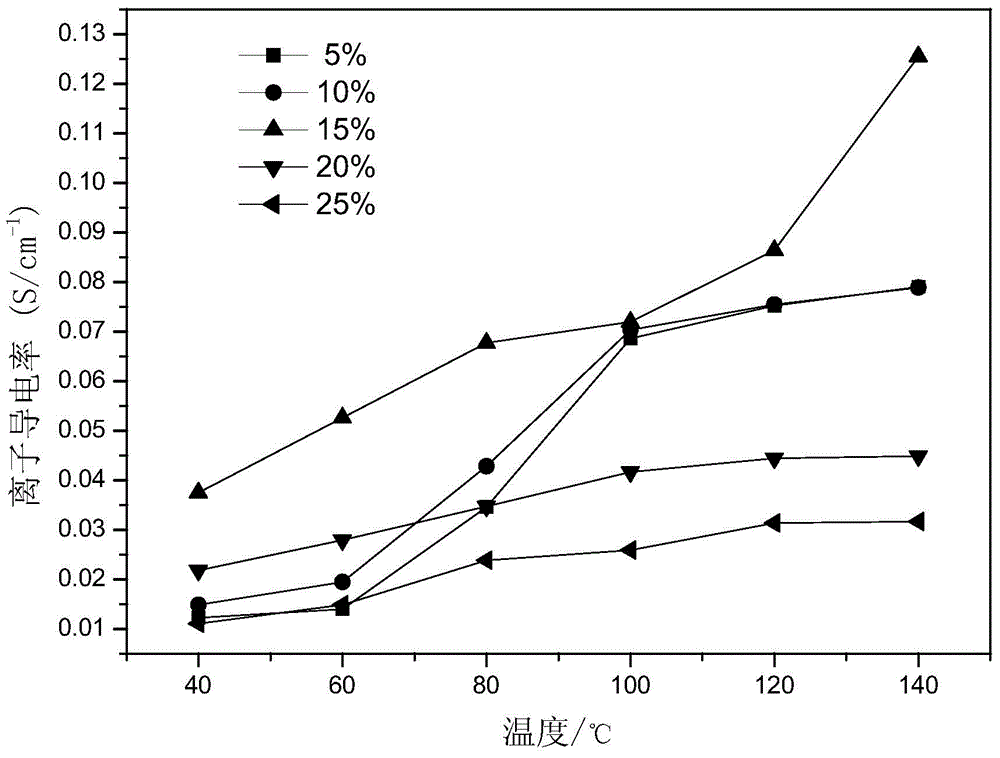

[0053] This example is the same as Example 1 except that different electrolyte monomers are selected as polymerized monomers in step (3). The electrolyte monomer of this example is prepared by the following steps: first, 20 mL of vinylimidazole is added to 41 mL of deionized water, and then the mixed solution is added dropwise to 36 mL of tetrafluoroboric acid. During the dropping process, tetrafluoroboric acid is always In an ice-water bath environment, continue to react in the ice-water bath state for 24 hours after the dropwise addition; then put the above liquid in a vacuum oven and bake at 40°C for 48 hours to remove the water in the solution; then use ether to dissolve the above The sample was washed 3 times to wash away the unreacted vinylimidazole monomer; then baked in a vacuum oven at 25°C for 24 hours to obtain the required electrolyte monomer; then it was configured into a volume concentration of 10%, 15%, 20%, 25% ethanol solution.

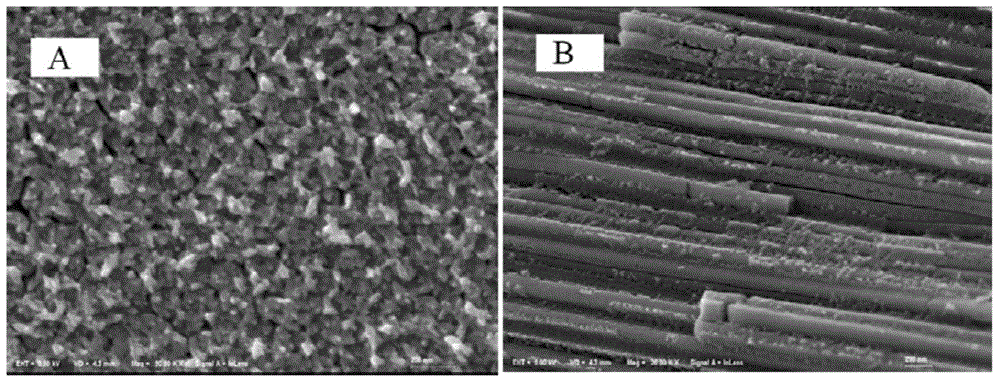

[0054] Take 5mL of electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com