Structural steel for construction with yield strength higher than 630mpa and preparation method thereof

A yield strength, 630mpa technology, applied in the field of high-strength construction steel production, can solve the problems of increased yield ratio, material waste, loss of strength, etc., to achieve uniform load and deformation, small fluctuation of yield strength, and improved plastic deformation capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

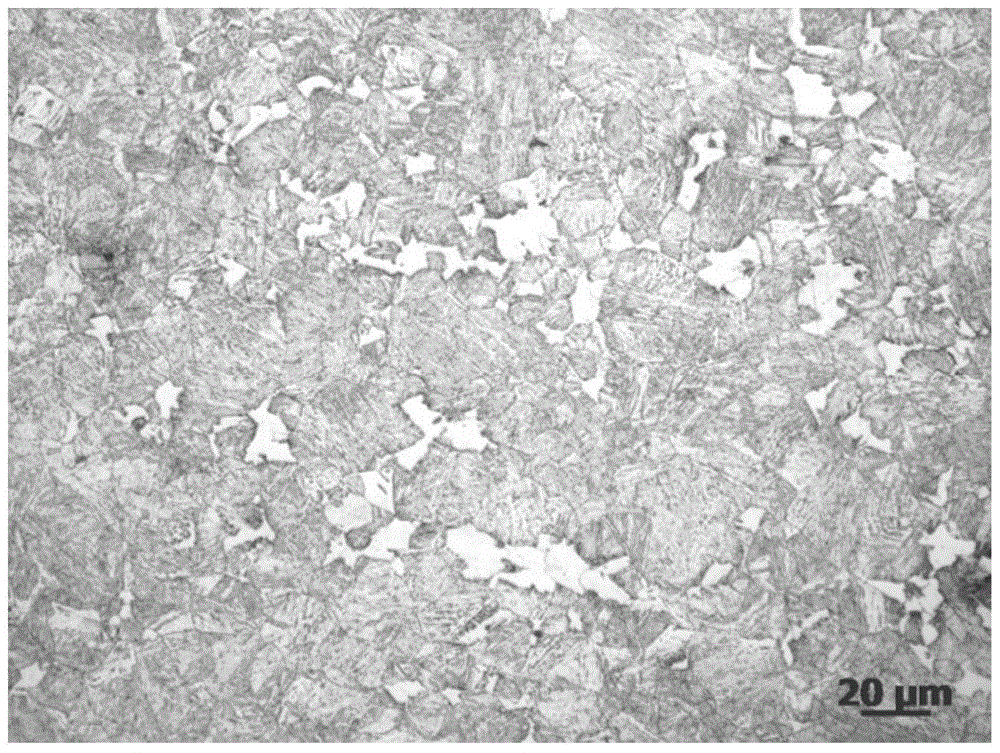

Embodiment 1

[0037] The structural steel of this embodiment has adopted following design:

[0038] The chemical composition and mass percentage of steel are: C0.087%, Si0.13%, Mn1.47%, P0.010%, S0.005%, V0.052%, Nb0.025%, Ti0.015% , Cr0.42%, B0.0014%, the balance is Fe and unavoidable impurity elements.

[0039] The method for preparing the structural steel with the above-mentioned compositional design comprises the following steps:

[0040] (1) Smelting, refining and continuous casting: the raw materials are configured according to the above chemical composition, and continuous casting slabs are obtained by adopting converter smelting, external refining and continuous casting processes.

[0041] (2) Heating: Heating the continuous casting slab to 1210°C, holding it for 90 minutes to obtain the heated slab, austenitizing the slab and avoiding coarse austenite grains caused by excessive heating. And ensure uniform austenitization of the billet.

[0042] (3) Rolling: The heated slab is su...

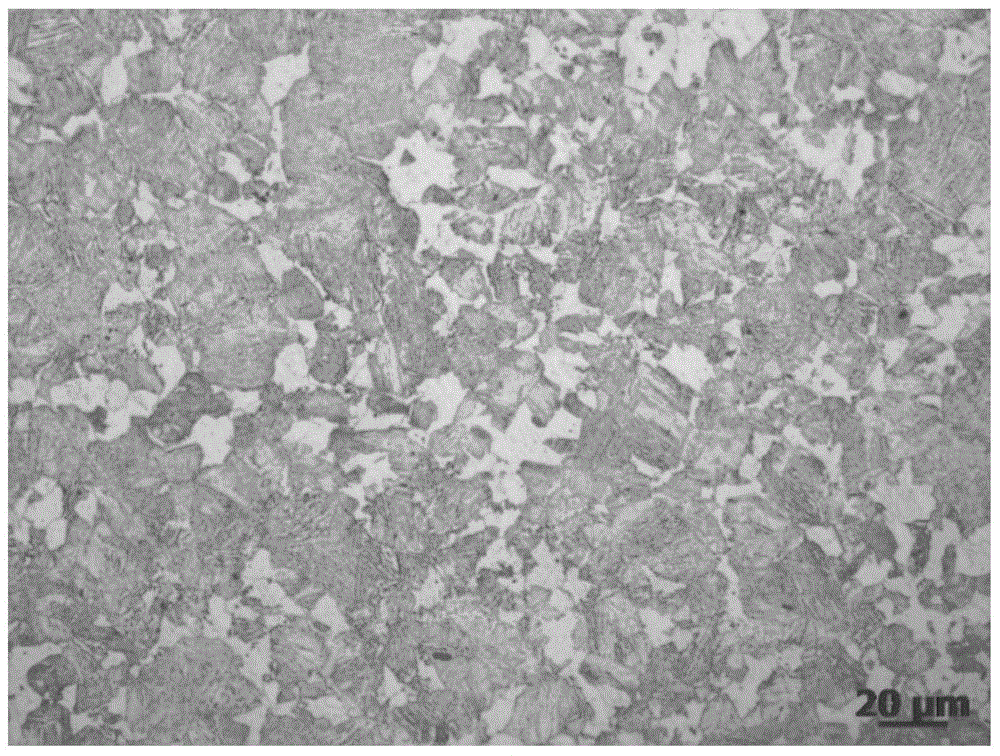

Embodiment 2

[0045] Embodiment 2: The structural steel of this embodiment adopts the following design:

[0046] The mass ratio of each chemical composition is: C0.11%, Si0.12%, Mn1.50%, P0.012%, S0.003%, V0.06%, Nb0.0275%, Ti0.018%, Cr0. 406%, B0.001%, the balance is Fe and unavoidable impurity elements.

[0047] The method for preparing the structural steel with the above-mentioned compositional design comprises the following steps:

[0048] (1) Smelting: According to the above chemical composition, the raw materials are configured, and the slab is obtained through converter smelting, external refining, and continuous casting.

[0049] (2) Heating: heat the slab obtained through the casting step, heat the slab to 1210°C, and keep it warm for 100 minutes to obtain the heated slab, so as to austenitize the slab and avoid austenitization caused by excessive heating. Coarse tenite grains ensure uniform austenitization of the slab.

[0050] (3) Rolling: The heated slab obtained through the ...

Embodiment 3

[0053] Embodiment 3: The structural steel of this embodiment adopts the following design:

[0054] The mass ratio of each chemical composition is: C0.09%, Si0.14%, Mn1.60%, P0.009%, S0.002%, V0.06%, Nb0.03%, Ti0.02%, Cr0. 42%, B0.001%, the balance is Fe and unavoidable impurity elements.

[0055] The method for preparing the structural steel with the above-mentioned compositional design comprises the following steps:

[0056] (1) Smelting: According to the above chemical composition, the raw materials are configured, and the slab is obtained through converter smelting, external refining, and continuous casting.

[0057] (2) Heating: heat the slab obtained through the casting step, heat the slab to 1220°C, and keep it warm for 100 minutes to obtain the heated slab, so as to austenitize the slab and avoid austenitization caused by excessive heating. Coarse tenite grains ensure uniform austenitization of the slab.

[0058] (3) Rolling: The heated cast slab obtained through the...

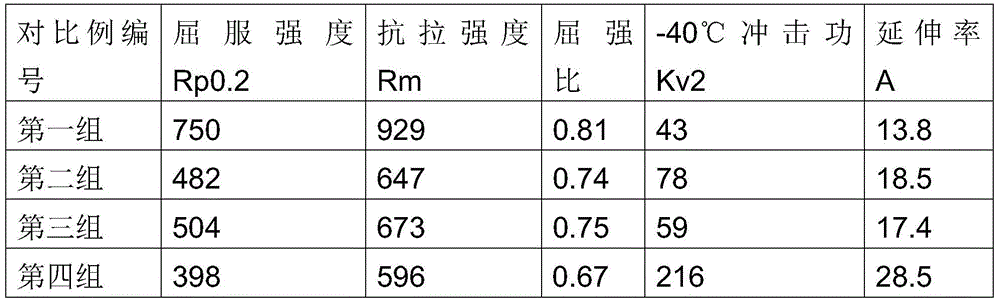

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com