Mg2Ni-based ternary Mg-Ni-Cu reversible hydrogen storage material and preparation method thereof

A hydrogen storage material and atomic percentage technology, applied in the field of hydrogen storage, to achieve the effects of less investment in production equipment, no pollution in the production process, and mild preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

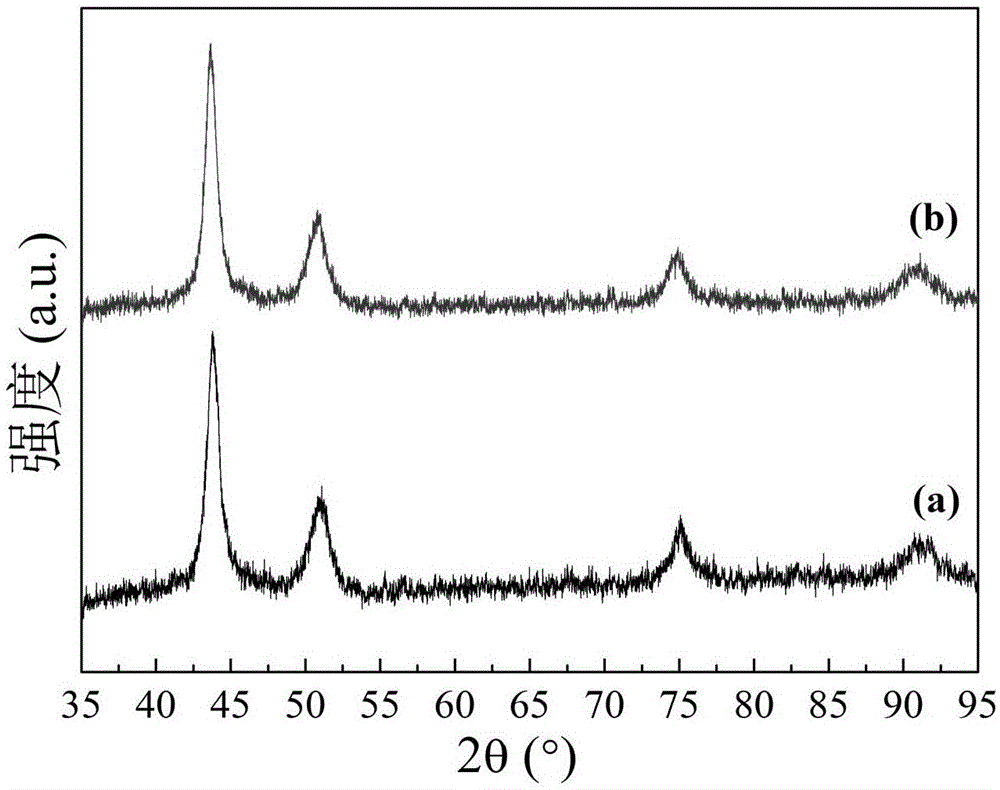

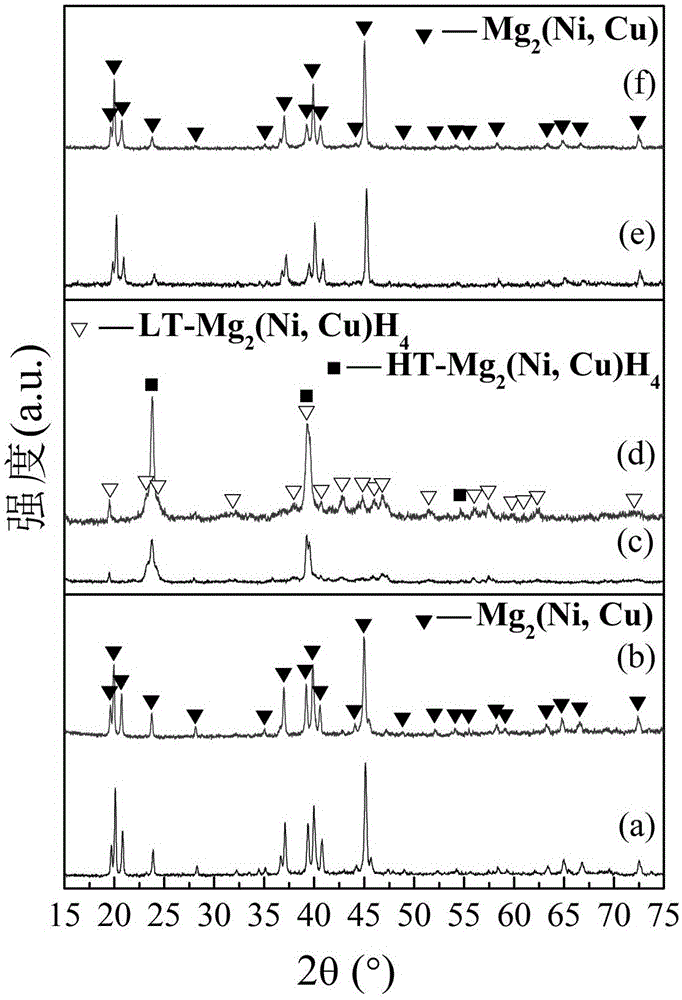

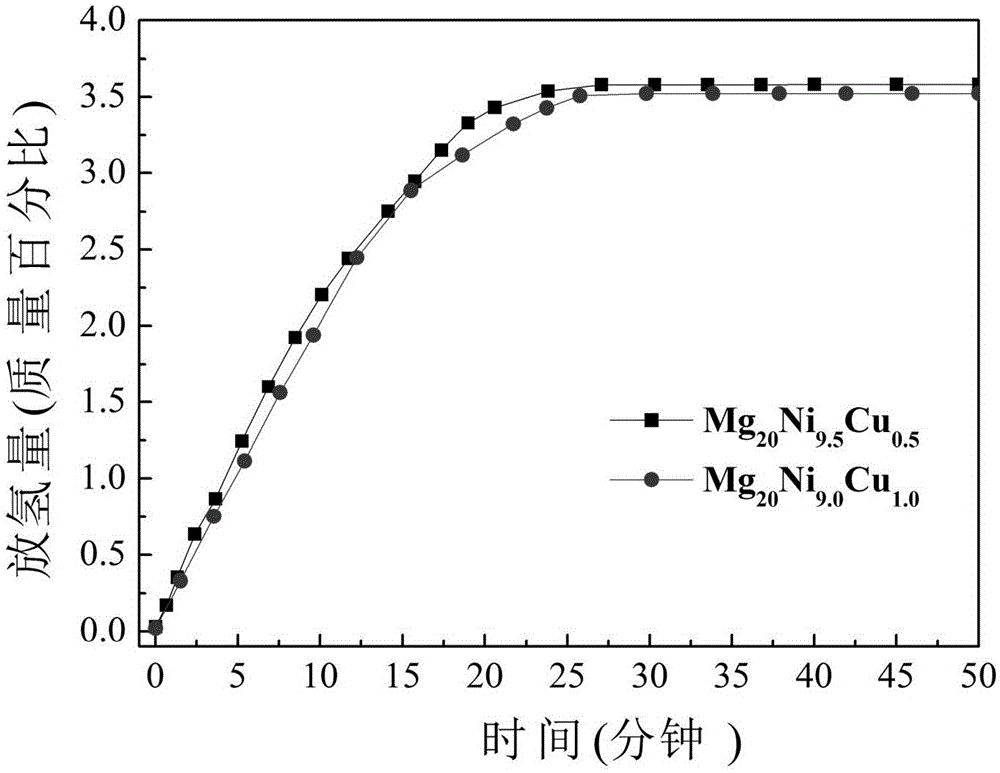

[0020] Press Ni 9.5 Cu 0.5 The composition of Ni powder (particle size 200 mesh, purity 99.5%) and Cu powder (particle size 200 mesh, purity 99.5%) were weighed respectively, Ni powder and Cu powder 25 grams altogether. Put the weighed Ni powder and Cu powder into a stainless steel ball mill tank, add stainless steel balls according to the ball-to-material ratio of 20:1, then pour industrial alcohol to submerge the balls and materials, and seal the ball mill tank cover. The ball mill pot was placed in a ball mill for wet ball milling for 40 hours, and the rotational speed of the ball mill was 200 rpm. After ball milling, dry in an oven at 40°C for 0.5h to remove industrial alcohol and obtain highly chemically stable Ni 9.5 Cu 0.5 Solid solution powder, the powder consists of a single Ni(Cu) solid solution phase (see figure 1 (a): Ni 9.5 Cu 0.5 Solid solution powder X-ray diffraction pattern). by Mg 20 Ni 9.5 Cu 0.5 The composition of Mg powder (particle size 200 mesh...

Embodiment 2

[0022] Press Ni 9.0 Cu 1.0 The composition of Ni powder (particle size 200 mesh, purity 99.5%) and Cu powder (particle size 200 mesh, purity 99.5%) were weighed respectively, Ni powder and Cu powder 25 grams altogether. Put the weighed Ni powder and Cu powder into a stainless steel ball mill tank, add stainless steel balls according to the ball-to-material ratio of 20:1, then pour industrial alcohol to submerge the balls and materials, and seal the ball mill tank cover. The ball mill pot was placed in a ball mill for wet ball milling for 40 hours, and the rotational speed of the ball mill was 200 rpm. After ball milling, dry in an oven at 40°C for 0.5h to remove industrial alcohol and obtain highly chemically stable Ni 9.0 Cu 1.0 Solid solution powder, the powder consists of a single Ni(Cu) solid solution phase (see figure 1 (b): Ni 9.0 Cu 1.0 Solid solution powder X-ray diffraction pattern). by Mg 20 Ni 9.0 Cu 1.0 The composition of Mg powder (particle size 200 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com