A magnetic gasoline conversion ring

A conversion ring and gasoline technology, applied in the field of automobile fuel, can solve the problems of easy accumulation of carbon deposits, fuel burnout, toxic and harmful gas emissions, etc., and achieve the effect of improving air quality, improving fuel quality, and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

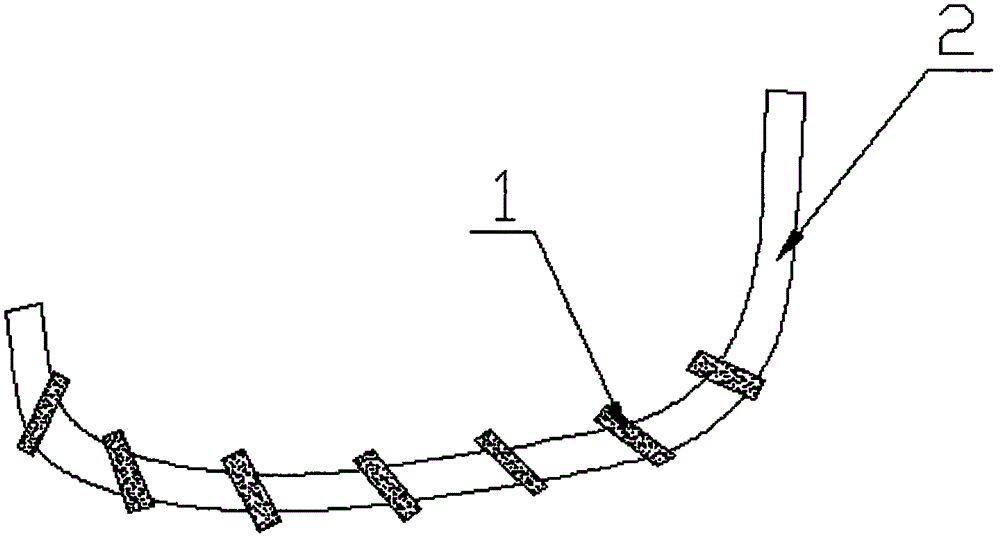

Embodiment 1

[0015] A magnetic gasoline conversion ring. The structure of the conversion ring is a spiral ring structure. The conversion ring includes the following components: 73% of silicone rubber, 8% of metal magnetic powder, 5% of volcanic rock, and 4% of flame retardant %, tourmaline powder 10%, the metal magnetic powder is metal soft magnetic powder, and the flame retardant is tetrabromobisphenol A.

Embodiment 2

[0017] A magnetic gasoline conversion ring, the structure of the conversion ring is a spiral ring structure, and the conversion ring includes the following components: 70% of silicone rubber, 9% of metal magnetic powder, 6% of volcanic rock, and 5% of flame retardant %, tourmaline powder 10%, the metal magnetic powder is metal soft magnetic powder, and the flame retardant is tetrabromobisphenol A.

Embodiment 3

[0019] A magnetic gasoline conversion ring. The structure of the conversion ring is a spiral ring structure. The conversion ring includes the following components: 75% of silicone rubber, 10% of metal magnetic powder, 4% of volcanic rock, and 3% of flame retardant %, tourmaline powder 8%, the metal magnetic powder is metal soft magnetic powder, and the flame retardant is tetrabromobisphenol A.

[0020] The present invention is completed from the following four kinds of energy, and achieves the expected effect and the purpose of effectively reducing automobile exhaust.

[0021] 1. Magnetic field energy

[0022] The energy of the magnetic field can hold the oil molecules tightly and gradually integrate the oil molecules into this super powerful magnetic field system. After the gasoline is treated with a strong magnetic field, it immediately becomes a magnetic gasoline, and the physical structure of the gasoline shrinks instantly, so that the oil molecules are arranged in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com