Double-layer high-strength fracturing propping agent and preparing method thereof

A fracturing proppant, high-strength technology, applied in chemical instruments and methods, earth drilling, mining fluids, etc., can solve the problems of weak corrosion resistance, low compressive strength, high apparent density, etc., and achieve strong corrosion resistance , High compressive strength, low apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

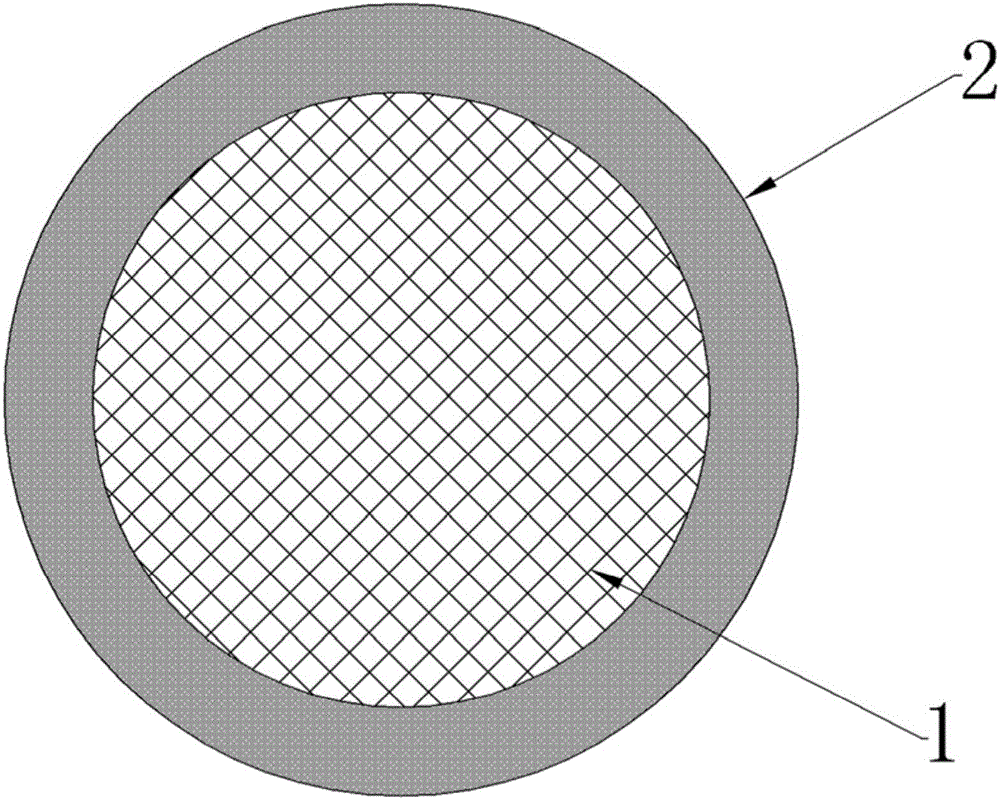

[0045] The double-layer high-strength fracturing proppant of this embodiment, such as figure 1 As shown, it includes a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the ratio of the diameter of the ceramic inner core 1 to the thickness of the silicon nitride ceramic shell 2 is 7:1;

[0046] The ceramic inner core is mainly made of the following core materials by mass percentage: 45% of low-bauxite, 45% of shale, and 10% of coal gangue; the mass content of alumina in the low-bauxite is 50%;

[0047] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 60% of silicon nitride and 40% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 70%;

[0048] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0049] 1) Take low bauxite, shale, and coal gangue and cr...

Embodiment 2

[0056] The double-layer high-strength fracturing proppant of this embodiment has the same structure as that of Embodiment 1, including a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the diameter of the ceramic inner core 1 is the same as The thickness ratio of the silicon nitride ceramic shell 2 is 5:1;

[0057] The ceramic inner core is mainly made of the following core materials by mass percentage: 50% of low-bauxite, 45% of shale, and 5% of coal gangue; the mass content of alumina in the low-bauxite is 40%;

[0058] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 70% of silicon nitride and 30% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 80%;

[0059] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0060] 1) Take low bauxite, shale, ...

Embodiment 3

[0066] The double-layer high-strength fracturing proppant of this embodiment has the same structure as that of Embodiment 1, including a ceramic inner core 1 and a silicon nitride ceramic shell 2 coated on the surface of the ceramic inner core 1, and the diameter of the ceramic inner core 1 is the same as The ratio of the thickness of the silicon nitride ceramic shell 2 is 10:1;

[0067] The ceramic inner core is mainly made of the following core materials by mass percentage: 47% of low-bauxite, 43% of shale, and 10% of coal gangue; the mass content of alumina in the low-bauxite is 45%;

[0068] The silicon nitride ceramic shell is mainly made of the following shell materials in mass percentage: 65% of silicon nitride and 35% of high alumina bauxite. The mass content of alumina in the high alumina bauxite is 75%;

[0069] The preparation method of the double-layer high-strength fracturing proppant of this embodiment comprises the following steps:

[0070] 1) Take low bauxite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com