Modified regenerated cellulose membrane and preparation method and application thereof

A regenerated cellulose film and regenerated cellulose technology, applied in the field of modified regenerated cellulose film and preparation, can solve the problems of no polyacrylamide, lack of registration, limitations, etc., and achieve controllable thickness and good biocompatibility , The effect of the simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

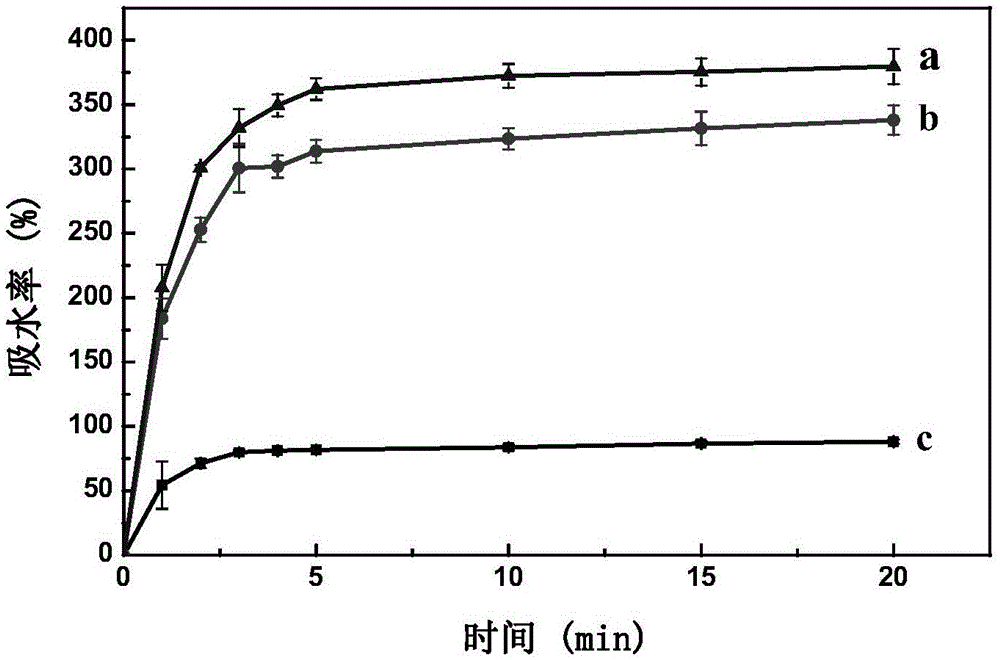

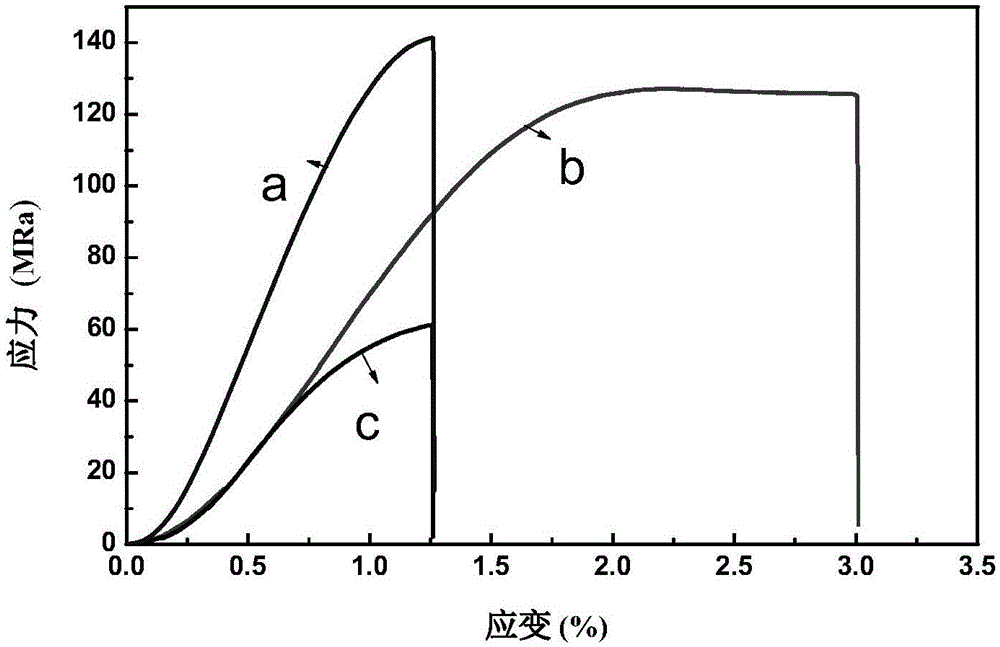

Embodiment 1

[0026] Dissolve short cotton cellulose in 7% NaOH / 12% urea aqueous solution to prepare a 4.6% cellulose solution. After defoaming, it is cast on a glass plate to form a 0.6mm solution layer, pre-solidified in the air for 30 minutes, and then immersed in the In the ethanol solution for 15 minutes, and then thoroughly washed with water, the regenerated cellulose gel membrane was obtained for use. A part of the cellulose gel film is immersed in a solution of acrylamide, the mass fraction of acrylamide is 7%, and the solvent is a mixed solution of alcohol and water. After soaking for 12 hours, blow nitrogen, add cerium ammonium nitrate initiator, react for 2 hours, add resorcinol terminator, react for 1 hour, after the reaction, wash with deionized water and acetone respectively to obtain polyacrylamide grafted cellulose modified film, and then dried for later use. Another part of the pure cellulose membrane is immersed in a solution of acrylamide, the mass fraction of acrylamide...

Embodiment 2

[0028] Use the ionic liquid 1-allyl-3-methylimidazole chloride as a solvent to dissolve cotton linter cellulose, the mass concentration of cellulose is 3%, cast on a glass plate to form a 1.5mm solution layer, and then immerse and solidify smoothly 15 minutes in bath water, and thoroughly washed with water to obtain a regenerated cellulose gel film for use. A part of the cellulose gel film is immersed in a solution of acrylamide, the mass fraction of acrylamide is 6%, and the solvent is a mixed solution of alcohol and water. After soaking for 10 hours, pass nitrogen gas, add cerium ammonium nitrate initiator, react for 1.5 hours, add resorcinol terminator, react for 40 minutes, after the reaction, wash with deionized water and acetone respectively to obtain polyacrylamide grafted cellulose The modified membrane was then dried for later use. Another part of the pure cellulose membrane was immersed in a solution of acrylamide, the mass fraction of acrylamide was 8%, and the sol...

Embodiment 3

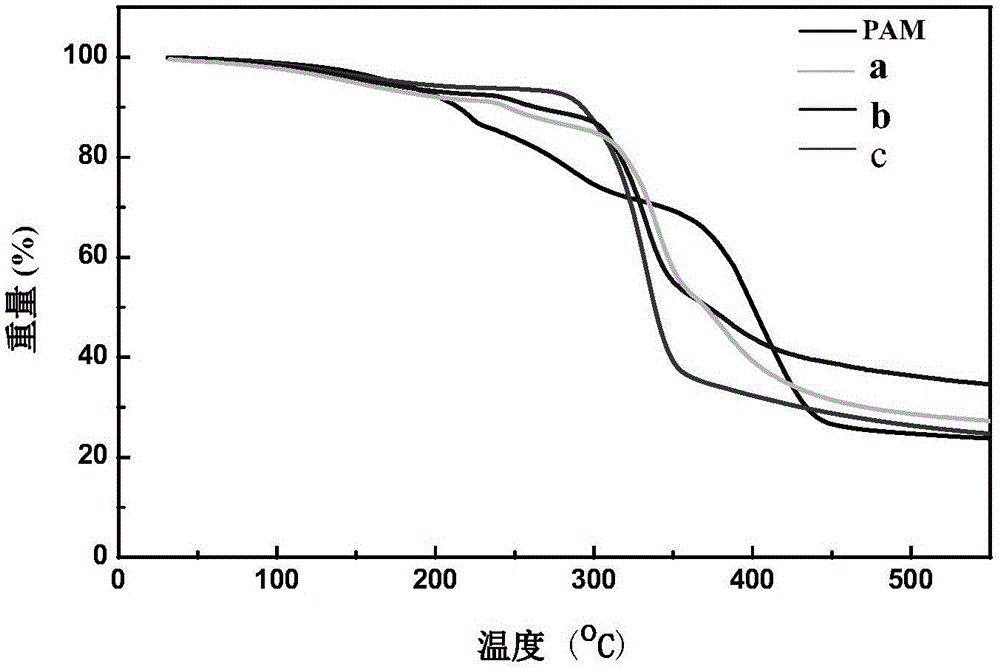

[0030] The regenerated cellulose gel film was prepared with the method in Example 1. A part of the cellulose gel film is immersed in a solution of acrylamide, the mass fraction of acrylamide is 3%, and the solvent is a mixed solution of alcohol and water. After soaking for 15 hours, pass nitrogen gas, add cerium ammonium nitrate initiator, react for 2 hours, add resorcinol terminator, react for 1 hour, after the reaction, wash with deionized water and acetone respectively to obtain polyacrylamide grafted cellulose modification film, and then dried for later use. Another part of the pure cellulose membrane was immersed in a solution of acrylamide, the mass fraction of acrylamide was 12%, and the solvent was water. After soaking for 15 hours, pass nitrogen gas, add ammonium persulfate initiator, react for 1 hour, end the reaction, wash with deionized water and acetone respectively to obtain an IPN film of polyacrylamide and cellulose, and then dry it for later use. Thermogravi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com