Coated glass being ultrahigh in visible light transmittance and preparation method thereof

A technology of coated glass and visible light, applied in the field of coated glass, can solve the problems of affecting indoor lighting and the attenuation of visible light transmittance, and achieve the effect of saving film material, improving corrosion resistance and low absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

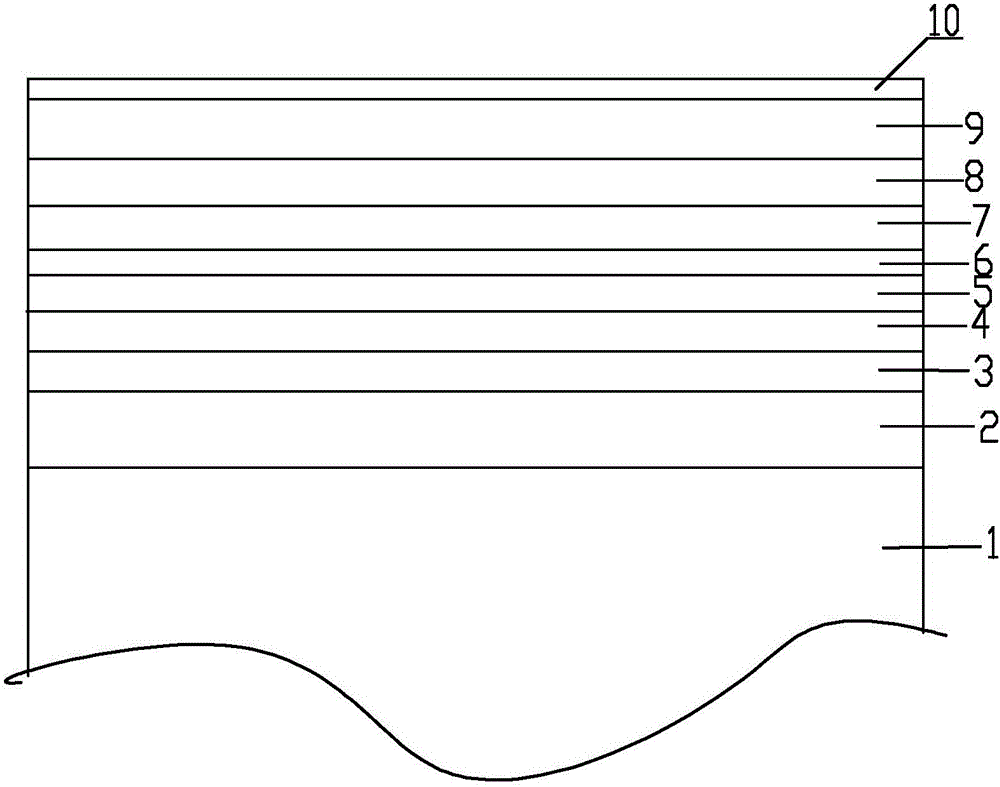

[0046] A coated glass with ultra-high visible light transmittance, including a glass substrate 1, which is a 6mm float white glass, including:

[0047] The first silicon nitride film layer 2 has high compatibility and improves the bonding force between the film layer and the glass substrate 1;

[0048] The first niobium oxide film layer 3 has a very low extinction coefficient, which reduces the absorption of visible light by the film layer and improves the visible light transmittance;

[0049] The zinc oxide aluminum film layer 4 has a dense and smooth surface structure, providing a film-forming platform for the silver film layer 5;

[0050] The silver film layer 5 has very high reflection characteristics for ultraviolet light, near-infrared light and far-infrared light, and reduces the emissivity value of the coated glass;

[0051] The nickel-chromium oxide film layer 6 not only prevents the silver film layer from being oxidized and corroded, but also has a very low extincti...

Embodiment 2

[0074] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0075] The thickness of the first silicon nitride film layer 2 is 27nm, the thickness of the first niobium oxide film layer 3 is 13nm, the thickness of the zinc-aluminum oxide film layer 4 is 13nm, the thickness of the silver film layer 5 is 12nm, and the nickel-chromium oxide film layer The thickness of 6 is 2nm, the thickness of zinc tin antimony film layer 7 is 12nm, the thickness of the second niobium oxide film layer 8 is 12nm, the thickness of the second silicon nitride film layer 9 is 26nm, the thickness of titanium oxide film layer 10 2nm.

[0076] After the coating is completed, the visible light transmittance of the glass is 90%, the apparent emissivity of the film surface is 0.08, and there are no visible defects such as pinholes and scratches.

Embodiment 3

[0078] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0079] The thickness of the first silicon nitride film layer 2 is 33nm, the thickness of the first niobium oxide film layer 3 is 16nm, the thickness of the zinc-aluminum oxide film layer 4 is 17nm, the thickness of the silver film layer 5 is 16nm, and the nickel-chromium oxide film layer The thickness of 6 is 3nm, the thickness of zinc tin antimony film layer 7 is 17nm, the thickness of the second niobium oxide film layer 8 is 16nm, the thickness of the second silicon nitride film layer 9 is 33nm, the thickness of titanium oxide film layer 10 4nm.

[0080] After the coating is completed, the visible light transmittance of the glass is 90%, the apparent emissivity of the film surface is 0.07, and there are no visible defects such as pinholes and scratches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com