Double-sided aluminum-based copper-clad plate for LED lamp and manufacturing method for double-sided aluminum-based copper-clad plate

A technology of aluminum-based copper-clad laminates and LED lamps, which is applied in chemical instruments and methods, lamination, lighting and heating equipment, etc., can solve the problems of increasing the cost of aluminum substrates and complicated processes, so as to avoid parasitic capacitance, simple insulation treatment, Improve the effect of anti-jamming function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

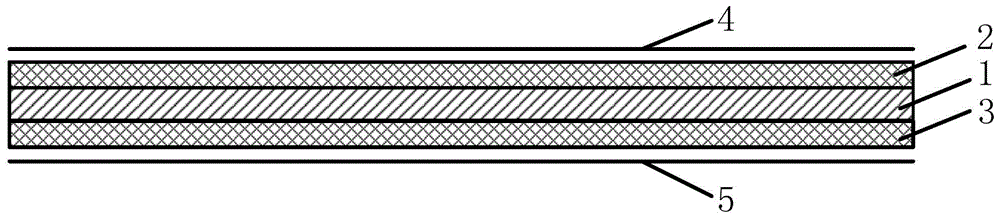

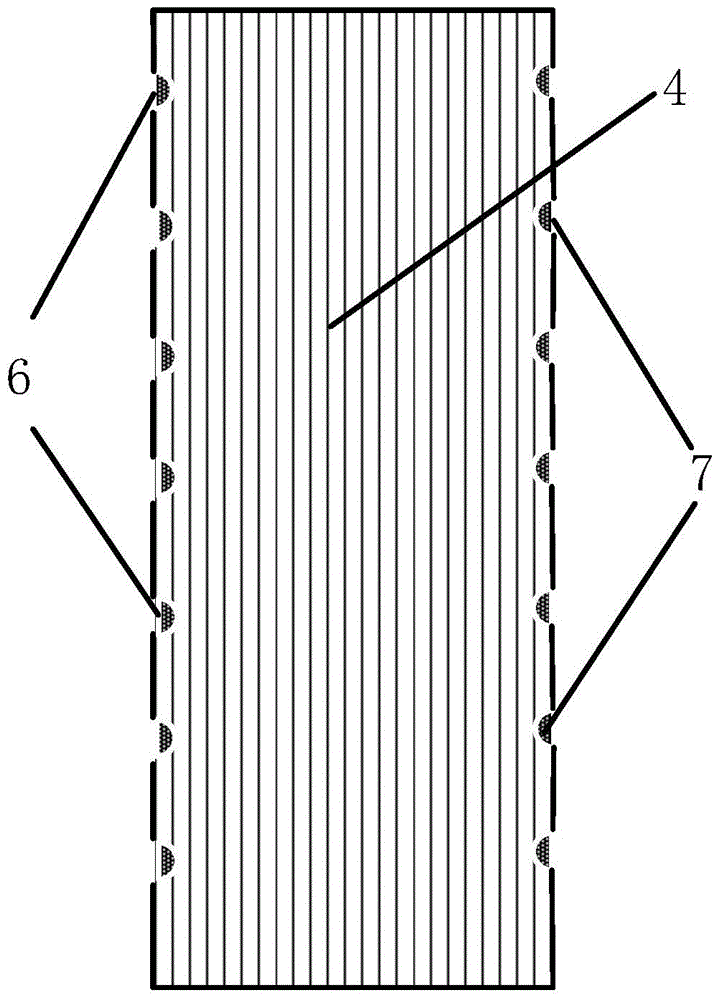

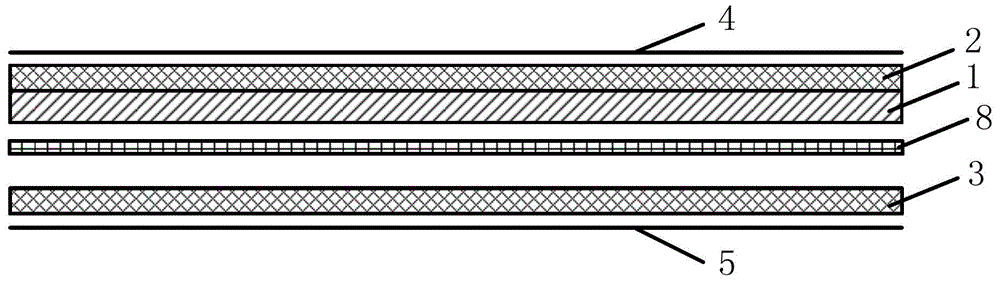

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0041]In the multilayer circuit board in the prior art, the circuit layer of the middle layer needs to be connected with its upper and lower layer circuits or external circuits, usually by processing metal vias on the circuit board. However, in the double-sided aluminum substrate, since the aluminum base layer in the middle is made of metal material, it is necessary to perform insulation treatment before making the metal via hole during the via hole processing, and the preparation process is very complicated; parasitic capacitance. In the circuit board used in the field of LED lamps, with the miniaturization of devices and the continuous maturity of SMT technology, both the light strip circuit and the more complex drive ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com