Board press used for bamboo chip tests

A technology for testing and plate pressing machines, applied in applications, household components, household appliances, etc., can solve the problems of inconvenient measurement and statistics, unsatisfactory, large size and shape, etc., to improve test efficiency, reduce errors, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

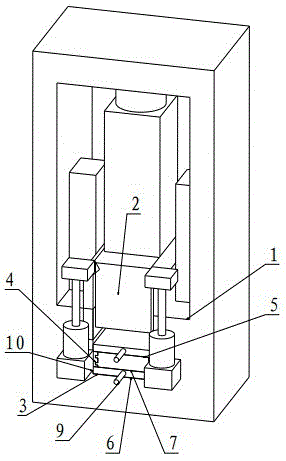

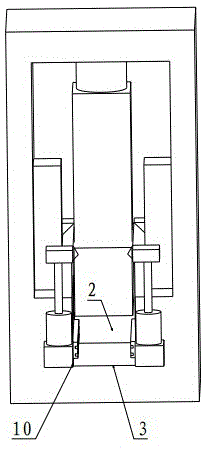

[0014] Such as figure 1 As shown, the platen press machine for bamboo chip test includes a worktable 1 and a vertical stamping plate 2 arranged on the normal side of its central part. The position directly below the stamping plate 2 on the worktable 1 is provided with a mold groove 3, and the mold groove The left and right sides of 3 are also provided with clamps 4, and the top and or bottom of the mold groove 3 are respectively provided with upper and lower heating molds 5, 6, and the bamboo board 7 to be formed is placed on the upper heating mold 5, the lower heating mold 6 and the stamping mold. Extrusion is carried out between the plate 2 and the fixture 4 . Plate pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com