A chamfering jig for a flat block at the end of a shaft

A shaft end and chamfering technology, which is applied in the field of chamfering fixtures, can solve the problems of inability to guarantee the chamfering quality, time-consuming and labor-intensive, low production efficiency, etc., and achieves the effect of simple structure, convenient use and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

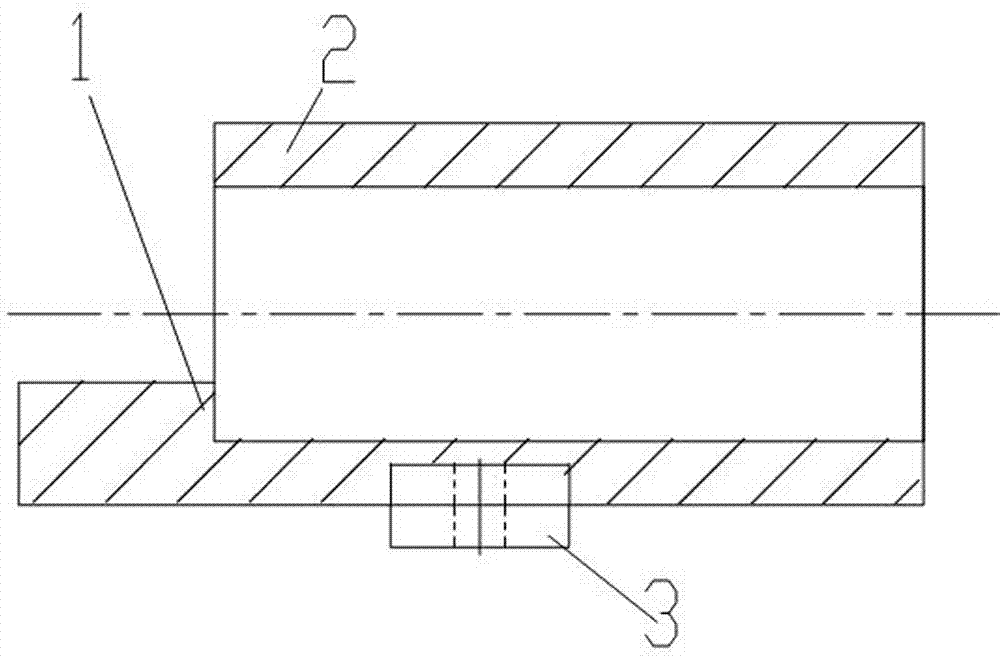

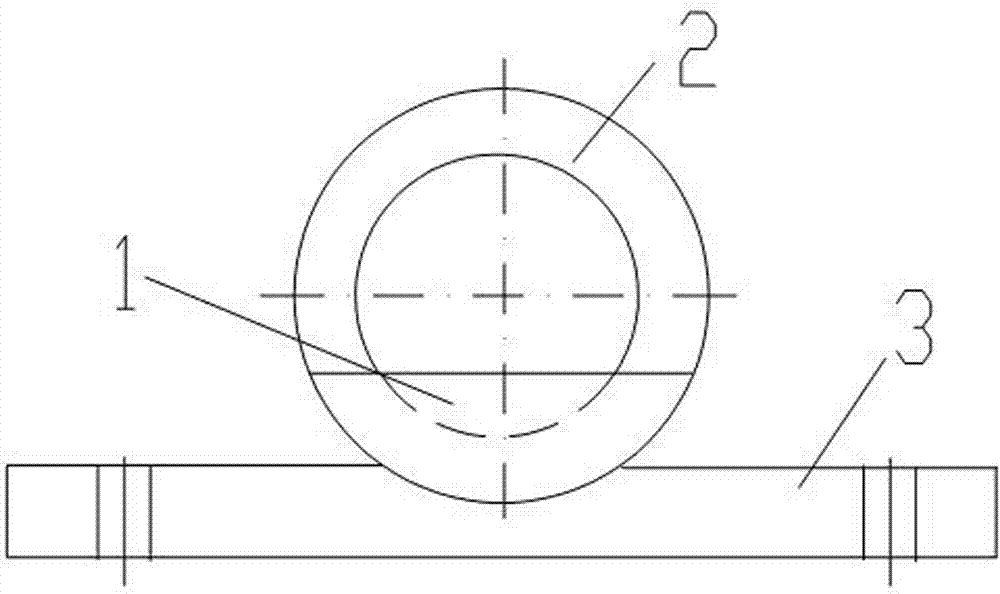

[0014] Embodiment 1: A chamfering jig for a flat block at the shaft end, including a shaft end sleeve 2, a blocking plate 1 and a fixing plate 3, the blocking plate 1 is a bow-shaped stop fixed on the inner wall of the left end of the shaft end sleeve 2 There is at least one arched baffle, and the fixed plate 3 is fixedly connected to both sides of the sleeve 2 . How to use: Insert the processed shaft 4 into the shaft end sleeve 2, block the shaft shoulder of the processed shaft 4 with the blocking plate 1, and make the shaft end flat block of the processed shaft 4 protrude. Since the processed shaft 4 is fixed as a whole, The operator holds the file to chamfer the flat block at the end of the shaft.

Embodiment 2

[0015] Embodiment 2: A chamfering jig for a flat block at the shaft end, including a shaft end sleeve 2, a blocking plate 1 and a fixing plate 3, the blocking plate 1 is a bow-shaped stop fixed on the inner wall of the left end of the shaft end sleeve 2 There is at least one arched baffle, and the fixed plate 3 is fixedly connected to both sides of the sleeve 2 . There are two blocking plates 1 and they are symmetrically fixed on the inner wall of the left end of the shaft end sleeve 2 . Using method is identical with embodiment 1.

Embodiment 3

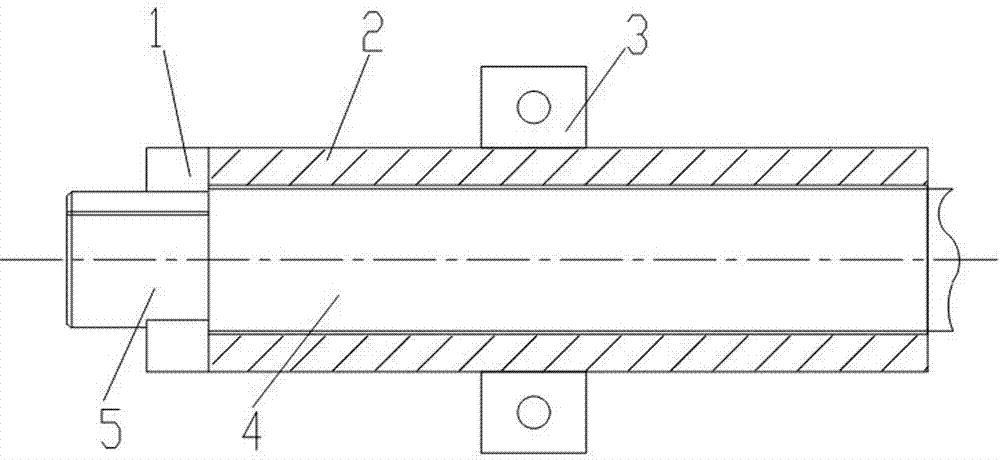

[0016] Embodiment 3: A chamfering jig for a flat block at the shaft end, including a shaft end sleeve 2, a blocking plate 1 and a fixing plate 3, the blocking plate 1 is a bow-shaped stop fixed on the inner wall of the left end of the shaft end sleeve 2 There is at least one arched baffle, and the fixed plate 3 is fixedly connected to both sides of the sleeve 2 . There are two blocking plates 1 and they are symmetrically fixed on the inner wall of the left end of the shaft end sleeve 2 . It also includes a workbench 6 and a supporting sleeve 9. There are two shaft end sleeves 2 symmetrically arranged at both ends of the workbench 6. The shaft end sleeve 2 at the left end is fixedly connected with the workbench 6, and the shaft end sleeve 2 at the right end is fixedly connected to the workbench 6. The end sleeve 2 is slidingly connected with the worktable 6 through the bolt 8 and the chute 7 on the worktable 6, and the support sleeve 9 is fixed on the worktable 6 between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com