A basic welding backing material

A welding backing and alkaline technology, which is applied in the field of backing materials and alkaline welding backing materials, can solve the problems of reduced impact toughness of weld seam and failure to meet the performance requirements of welded joints, etc., and achieve uniform and smooth welding seam formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: by weight content 43.56%MgO and CaO, 33.84%SiO of each oxide component in the final product material 2 , 18.42%Al 2 o 3 , 1.53% Fe 2 o 3 , 3.04% Na 2 O and K 2 The proportion of O, take the powder of these oxides or mineral powder containing these oxides such as clay, feldspar, bauxite, magnesite, etc. as raw materials, mix and granulate the raw materials, and then press and sinter to obtain the liner Liner block material with a slag basicity of 1.06.

Embodiment 2

[0034] Embodiment 2: press the weight content of each oxide component in the final product material 54.21%MgO and CaO, 27.64%SiO 2 , 13.54%Al 2 o 3 , 1.54% Fe 2 o 3 , 2.74% Na 2 O and K 2 The proportion of O, take the powder of these oxides or mineral powder containing these oxides such as clay, feldspar, bauxite, magnesite, etc. as raw materials, mix and granulate the raw materials, and then press and sinter to obtain the liner Liner block material with a slag basicity of 1.56.

Embodiment 3

[0035] Embodiment 3: by weight content 64.54%MgO and CaO, 26.66%SiO of each oxide component in the final product material 2 , 7.2% Al 2 o 3 , 1.68% Fe 2 o 3 , 1.53% Na 2 O and K 2 The proportion of O, take the powder of these oxides or mineral powder containing these oxides such as clay, feldspar, bauxite, magnesite, etc. as raw materials, mix and granulate the raw materials, and then press and sinter to obtain the liner Liner block material with a slag basicity of 2.05.

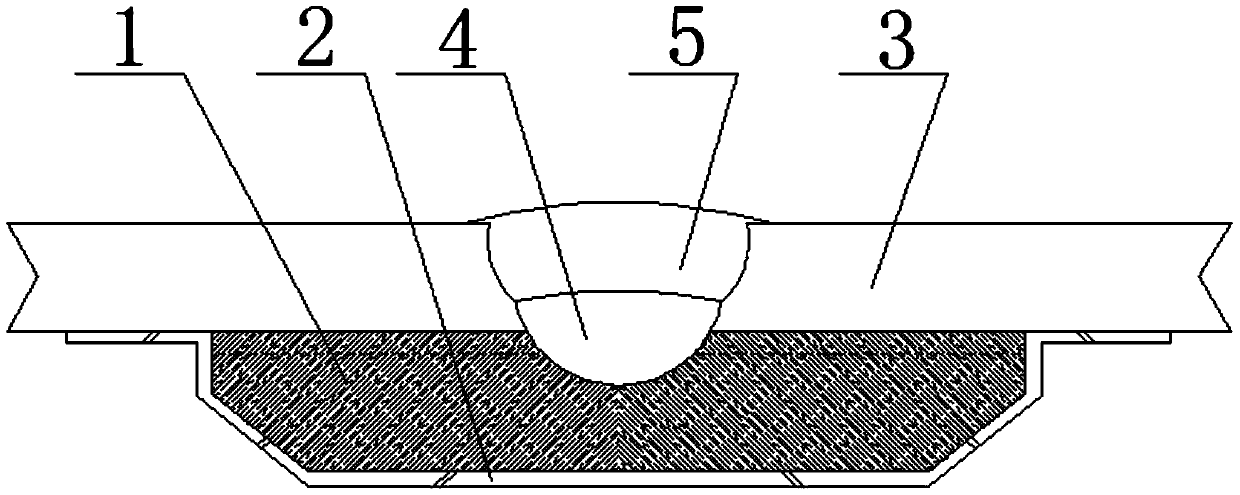

[0036] like figure 1 As shown, paste the back of the ceramic liner material 1 listed in the above embodiment and the aluminum foil pressure-sensitive adhesive 2 together, and then attach the aluminum foil pressure-sensitive adhesive 2 together with the ceramic liner material 1 to the welded steel plate 3 On top, rooting welding 4 and filling welding 5 are carried out, and the test conditions are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com