Copper/silver core-shell nanoparticles low-temperature sintering composite solder paste and preparation method thereof

A technology of copper nanoparticles and nanoparticles, which is applied in the field of material processing, can solve problems such as easy oxidation and electromigration, and achieve the effects of reducing sintering energy, solving easy oxidation, and increasing thermal stability temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

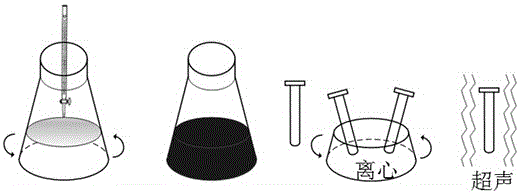

[0030] Specific implementation mode 1: In this implementation mode, copper / silver core-shell nanoparticle low-temperature sintering composite solder paste is prepared according to the following steps:

[0031] Step 1: If figure 1 As indicated, add 1 g of K90 polyvinylpyrrolidone into a conical flask containing 100 ml of polyethylene glycol, heat to 160 °C and stir until the polyvinylpyrrolidone is completely dissolved in the polyethylene glycol middle;

[0032] Step 2: Add 0.5 g of sodium hydrogen hypophosphite into the above solution and stir until completely dissolved;

[0033] Step 3: Add 1.5 g of copper sulfate to 20 ml of aqueous solution and stir to completely dissolve it;

[0034] Step 4: Add the copper sulfate aqueous solution dropwise to the polyethylene glycol solution containing polyvinyl pyrrolidone and sodium hydrogen hypophosphite, while stirring, the color of the solution gradually changes from colorless to yellow, orange, gray, black, and Finally stabilized ...

specific Embodiment approach 2

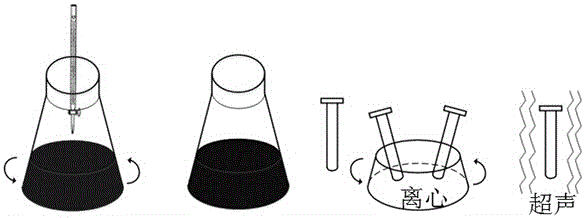

[0045] Specific implementation mode 2: In this implementation mode, copper / silver core-shell nanoparticle low-temperature sintering composite solder paste is prepared according to the following steps:

[0046] Step 1: Add 1 g of K90 polyvinylpyrrolidone into a conical flask containing 100 ml of polyethylene glycol, heat to 190 °C and stir until the polyvinylpyrrolidone is completely dissolved in the polyethylene glycol middle;

[0047] Step 2: Add 0.5 g of sodium hydrogen hypophosphite into the above solution and stir until completely dissolved;

[0048] Step 3: Add 1.5 g of copper sulfate to 20 ml of aqueous solution and stir to completely dissolve it;

[0049] Step 4: Add the copper sulfate aqueous solution dropwise to the polyethylene glycol solution containing polyvinyl pyrrolidone and sodium hydrogen hypophosphite, while stirring, the color of the solution gradually changes from colorless to yellow, orange, gray, black, and Finally stabilized in purple;

[0050] Step 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com