Laser cutting method for sapphire substrate LED chip

A technology of LED chips and sapphire substrates, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low yield, improve the cutting yield and reduce the phenomenon of oblique cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

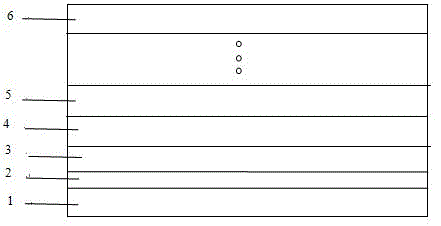

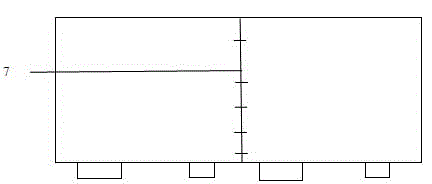

[0026] The cutting method of the sapphire substrate LED chip of the present invention is suitable for LED chips with a thickness ≥ 130 μm, comprising the following steps:

[0027] (1) Paste the LED chip on the white film 1 of SPV-224S type, the epitaxial layer 2 and the electrode surface of the LED chip are in contact with the white film 1, and the sapphire substrate is facing upward, and placed on the invisible cutting machine workbench.

[0028] (2) Set the focus of the stealth cutting laser so that the stealth cutting laser acts on the inside of the chip, close to the bottom, and cut at a distance of 50-100 μm from the bottom to form the first modified layer 3 .

[0029] Stealth cutting laser power 180-300mW (laser frequency 50KHz). The cutting speed is 250-550mm / s.

[0030] The modified layer refers to the use of a laser with a certain wavelength to focus on the inside of the workpiece material to form a starting point for division. The part around the starting point that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com