Preparation method for oil-phase silver nanoparticles

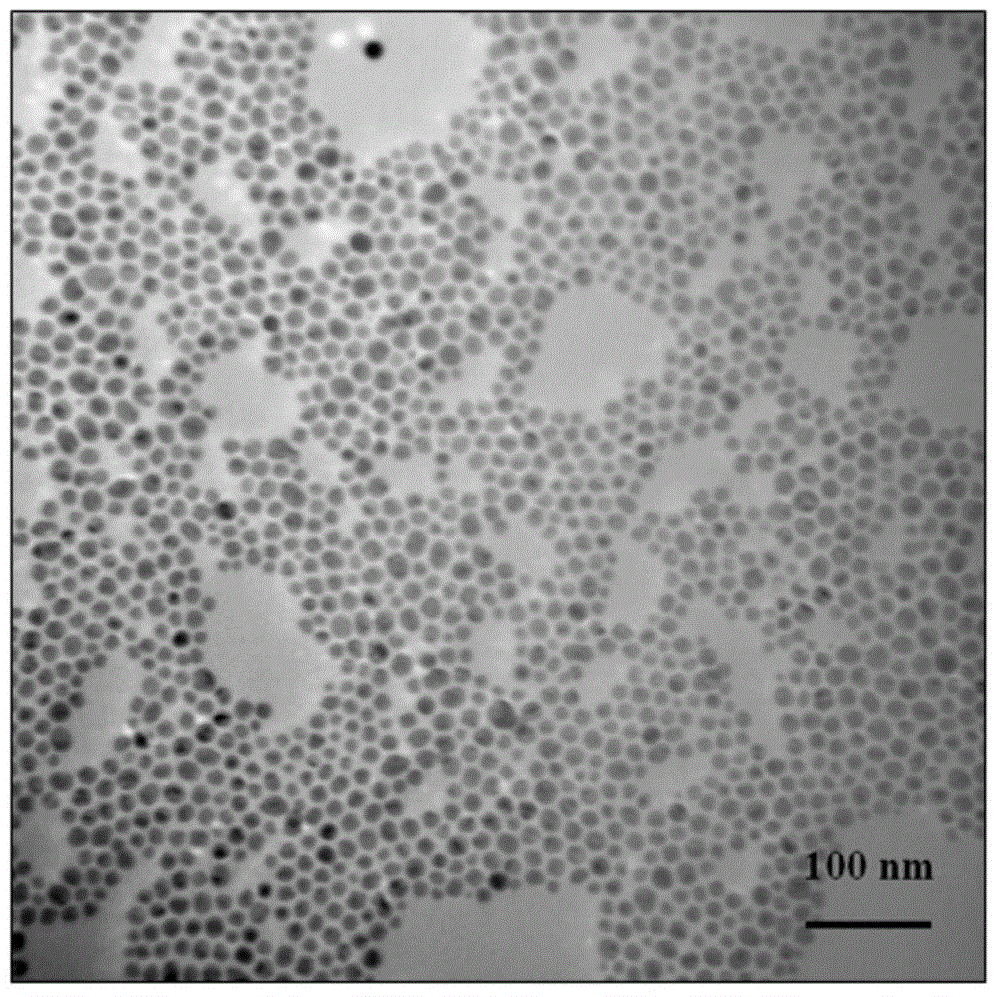

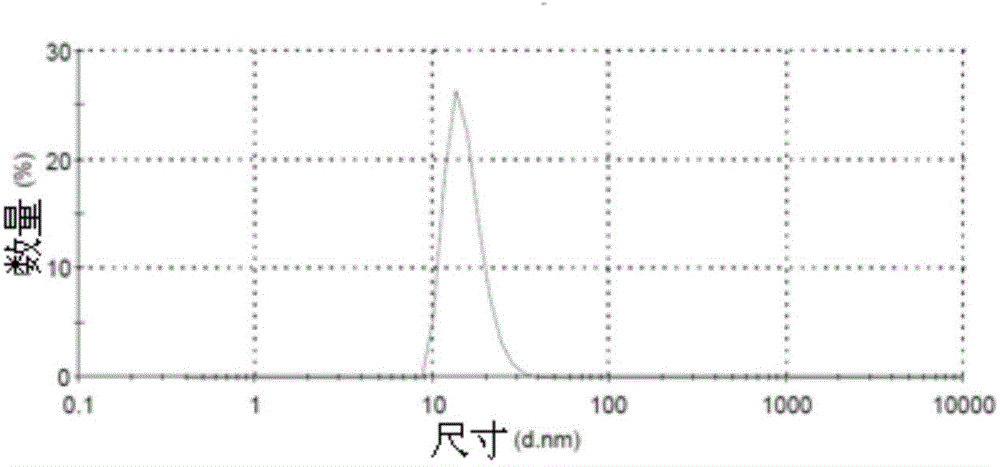

A technology of silver nanoparticles and oil phase, which is applied in the field of preparation of oil phase silver nanoparticles, can solve the problems of high production cost and poor solubility of silver salt, and achieve the effects of low production cost, narrow particle size distribution and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take by weighing 20.4g sodium stearate and be dissolved in the mixed solution of 800mL water, ethanol, cyclohexane, control the mass ratio of water, ethanol, cyclohexane to be 1:1.18:0.17;

[0048]Turn on the supergravity rotation device and adjust the rotation speed to 1200rpm;

[0049] Turn on the feed pump to transport the microemulsion to the rotating bed;

[0050] Add successively the silver nitrate aqueous solution of 60mL0.2mol / L, the hydrazine hydrate aqueous solution of 60mL8.16mol / L and carry out reduction reaction, and the feeding rate of controlling silver salt solution and reducing agent solution is 6mL / min, the temperature of control reaction system is 50°C, the reaction time is 5 minutes; after the reaction is completed, the nano-silver microemulsion obtained from the reaction flows out of the supergravity rotating device, and then close the supergravity rotating device;

[0051] Add hexanaphthene in reaction liquid, leave standstill after stirring;

[...

Embodiment 2

[0060] Take by weighing 30.6g sodium stearate and be dissolved in the mixed solution of 1000mL water, ethanol, cyclohexane, control the mass ratio of water, ethanol, cyclohexane to be 1:1.58:0.14;

[0061] Turn on the high-gravity rotating device and adjust the speed to 800rpm; turn on the feed pump and transport the microemulsion to the rotating bed; add 50mL of 0.45mol / L silver nitrate ethanol solution and 50mL of 9.24mol / L hydrazine hydrate ethanol solution for reduction React, and control the feed rate of silver salt solution and reducing agent solution to be 10mL / min, control the temperature of the reaction system to be 25°C, and the reaction time to be 10min; After installation, turn off the hypergravity spinner

[0062] Add hexanaphthene in reaction liquid, leave standstill after stirring;

[0063] Add absolute ethanol to the dispersed solution, centrifuge and wash, and disperse in cyclohexane again to obtain nano silver dispersion.

[0064] The product is dark red, a...

Embodiment 3

[0066] Weigh 70.6g sodium oleate and dissolve in 780mL water, ethanol, n-hexane mixed solution, control the mass ratio of water, ethanol, n-hexane to be 1:1.1:0.14;

[0067] Turn on the high-gravity rotating device and adjust the speed to 1500rpm; turn on the feed pump and transport the microemulsion to the rotating bed; add 40mL of 0.45mol / L silver nitrite ethanol solution and 60mL of 8.06mol / L sodium borohydride aqueous solution in sequence Reduction reaction, and control the feed rate of silver salt solution and reducing agent solution to be 20mL / min, control the temperature of the reaction system to be 0°C, and the reaction time to be 15min; After spinning the device, turn off the hypergravity rotation device;

[0068] Add n-hexane to the reaction solution, stir and let stand;

[0069] Add anhydrous methanol into the dispersed solution, centrifuge and wash, and disperse in n-hexane again to obtain nano silver dispersion.

[0070] The product is dark red, and there is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com