a tubular motor

A technology of tubular motor and manual mechanism, applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of increasing the number of operators, laborious unlocking process, slowness, etc., and achieve the effect of labor-saving manufacturing cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

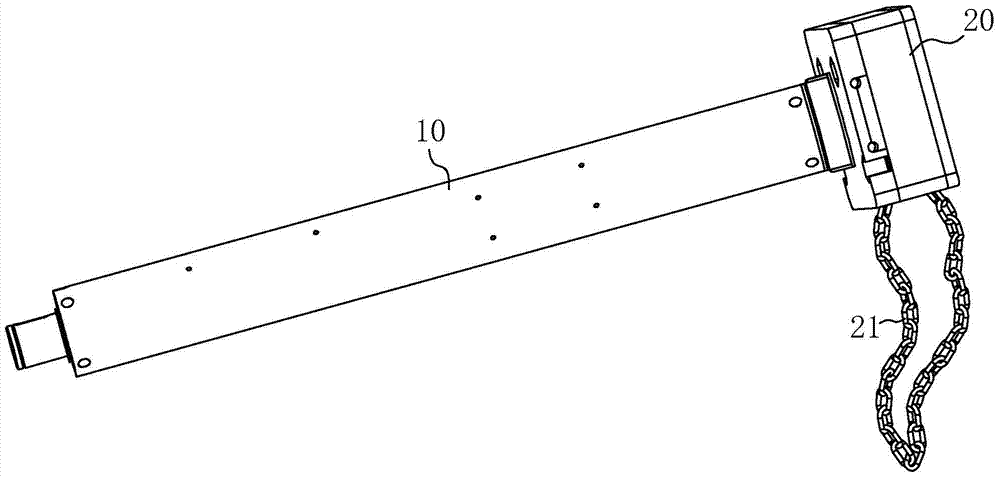

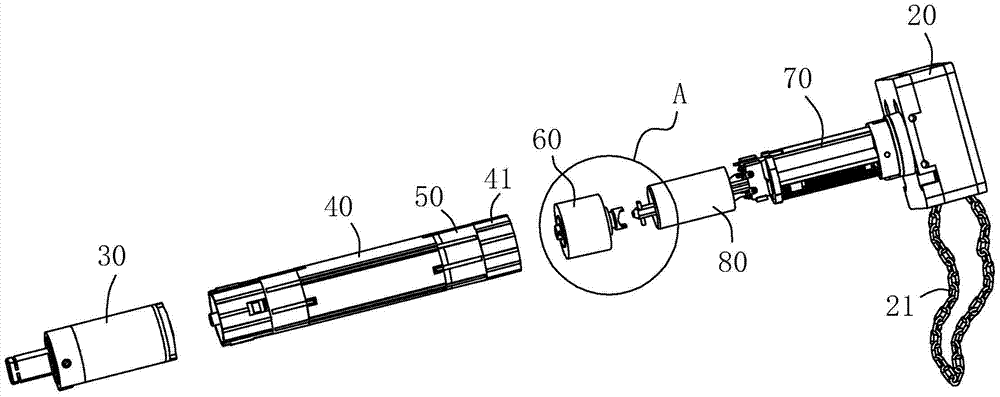

[0043] to combine figure 1 and figure 2 , a tubular motor includes a reduction device 30, a motor 40, a brake device 50, a clutch device, and a travel device 70 in sequence. The travel device 70 includes a manual mechanism 20 connected to one side, and the manual mechanism 20 includes internally arranged gears that wind around the gears. The chain 21 and the long shaft 71 rotating with the gear pull the chain 21 to drive the gear to rotate so as to drive the long shaft 71 to rotate. The long shaft 71 runs through the capacitor 80, and the capacitor 80 is connected with the travel device 70 to provide a starting current. The motor pipe 10 is sleeved on the outside and is fixed by screws and the reduction device 30, the clutch device and the stroke device. The motor pipe 10 in the present invention is fixed and does not rotate.

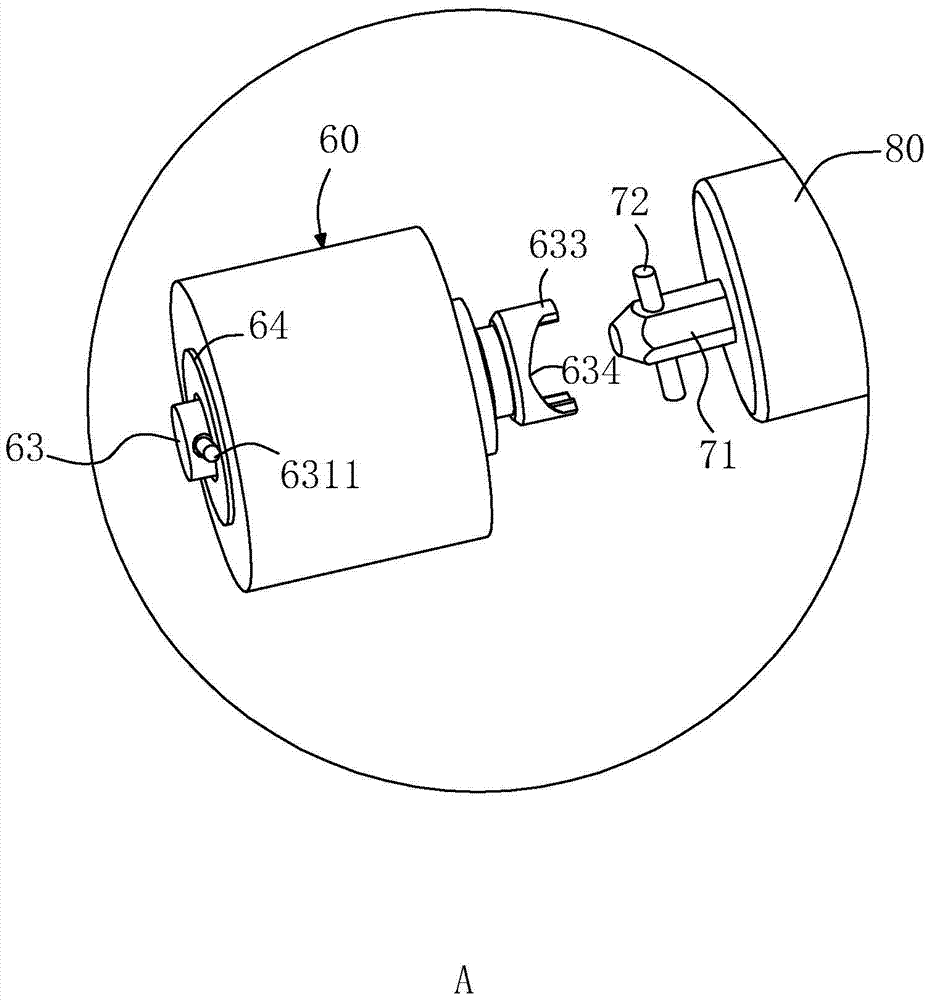

[0044] see Figure 3 to Figure 5 , the clutch device includes a lower clutch 60, the lower clutch 60 includes a clutch seat 61 and a clutch member 6...

Embodiment 2

[0053] The difference between Embodiment 1 lies in the operation mode of the manual mechanism 60. The gear in the manual mechanism 60 is changed to a worm gear transmission mode, and the worm is connected to a manual shaft to drive the worm gear to rotate, thereby driving the long axis 71 to rotate.

Embodiment 3

[0055] The difference between Embodiment 1 lies in the operation mode of the manual mechanism 60. The gear in the manual mechanism 60 is changed to a long-axis bevel gear, and the long-axis bevel gear is fixed to the long-axis 71, and a hand-shaft bevel gear is provided to mesh with the long-axis bevel gear. , The bevel gear of the hand shaft is driven to rotate by the hand shaft.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap