Developing device and photoetching equipment

A developing device and photoresist technology, applied in the processing of photosensitive materials, etc., can solve problems affecting product quality, open circuit, etc., achieve the effect of improving the uniformity of development, increasing the speed of development, and preventing the disconnection of the active layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] As another specific embodiment of the present invention, the control mechanism can control the opening state and / or heating temperature of each heating member 21 according to the development speed of each development position on the substrate when the substrate is not heated, so that During the developing process, the developing speeds of the plurality of developing positions on the substrate 30 are the same.

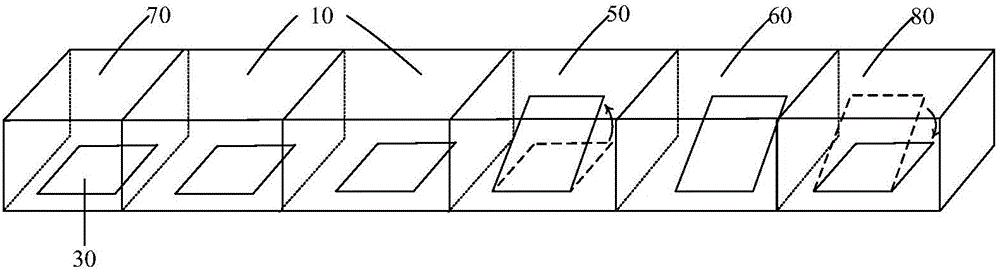

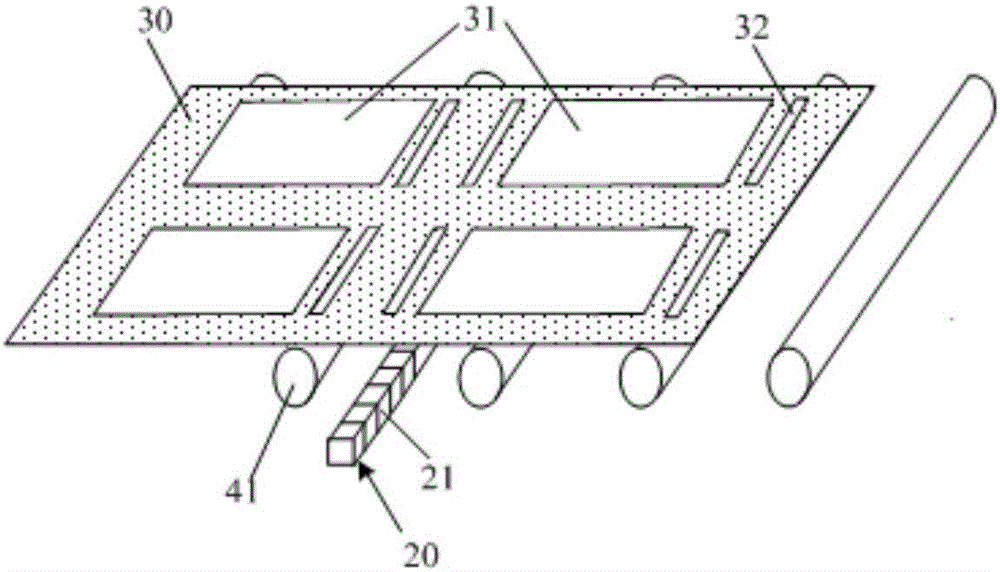

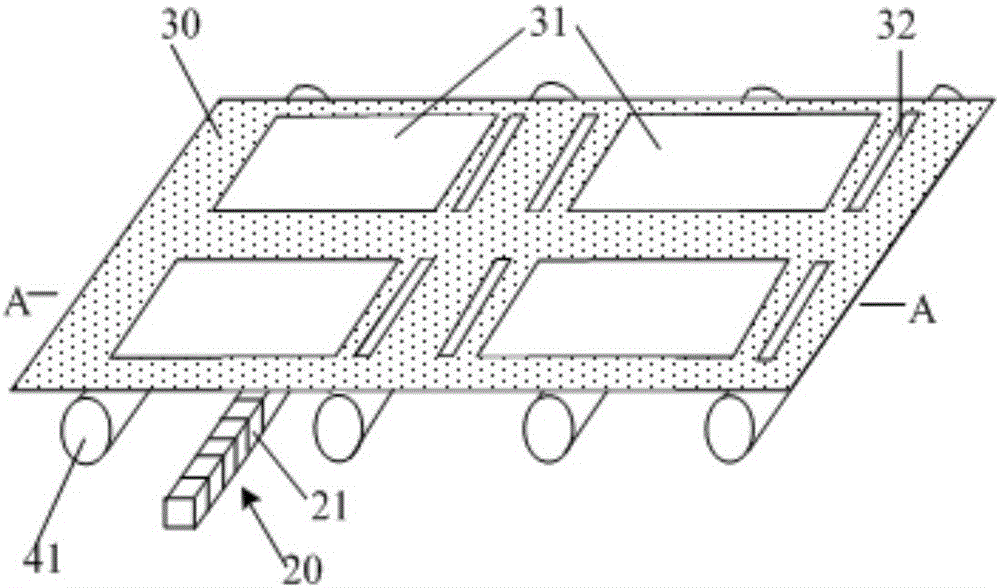

[0035] Such as figure 2 , image 3 with Image 6As shown, the substrate 30 includes a display area 31 and a driving area 32 for setting a gate driving circuit around the display area. In order to make the developing speeds of the display area 31 and the non-display area consistent, the heating mechanism may include two independently controlled heating elements, which are respectively used to heat the display area and the periphery of the display area of the substrate above the heating mechanism. The drive zone is heated, and the control mechanism can contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com