An eddy current testing equipment for long ball pins

A technology of eddy current flaw detection and testing equipment, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means. It can solve the problems of magnetic particle environment, human hazards, and low manual operation efficiency, and achieve high work efficiency, fast automatic detection, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

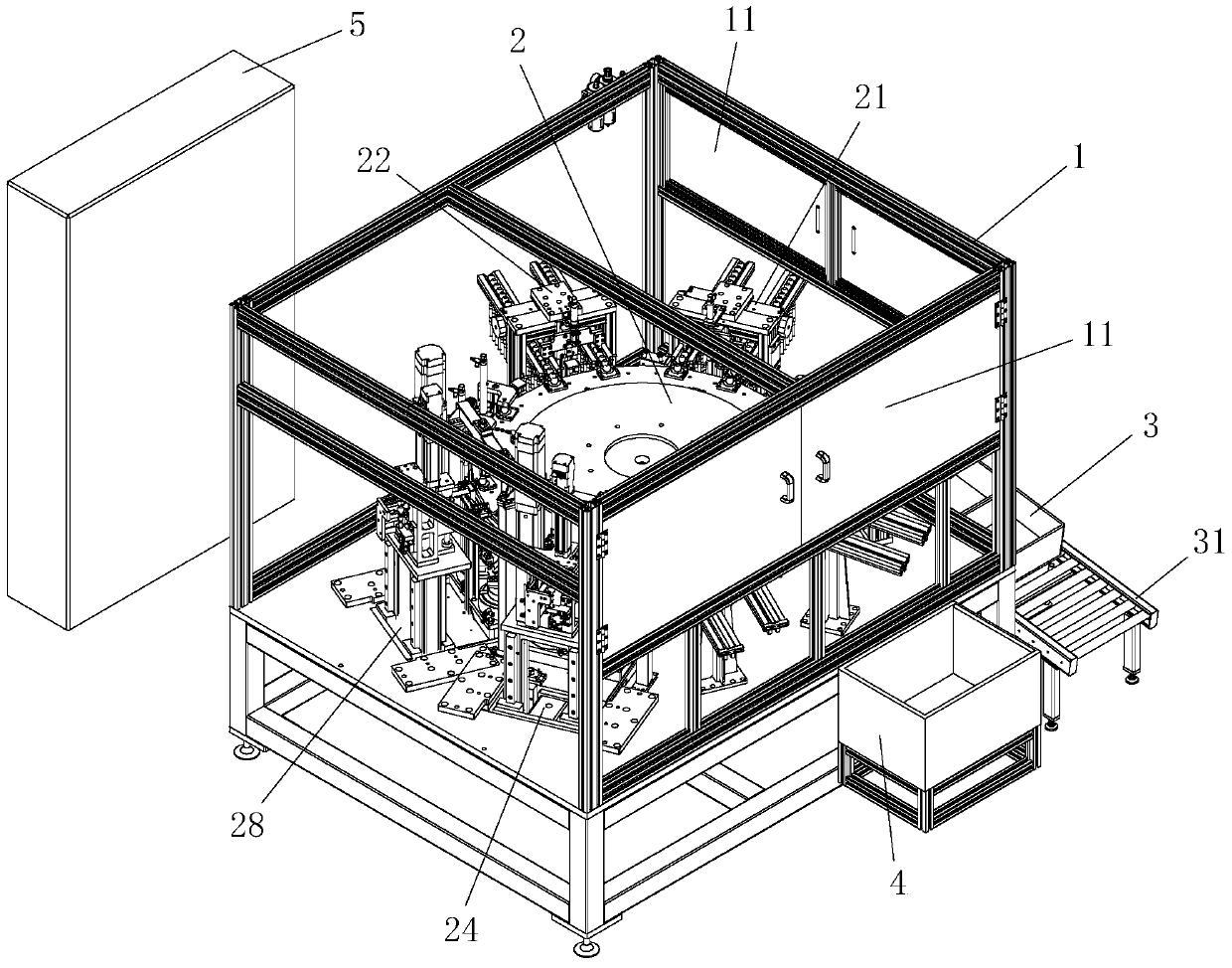

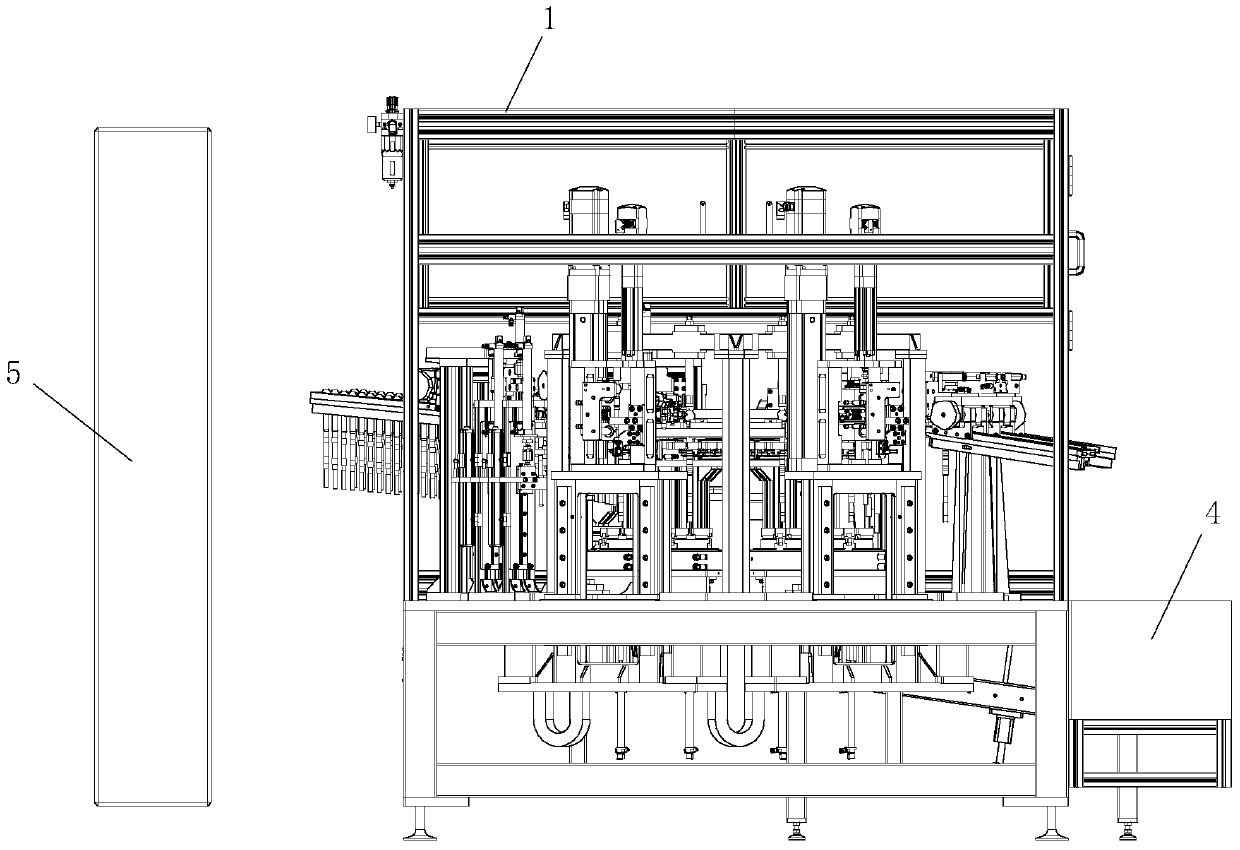

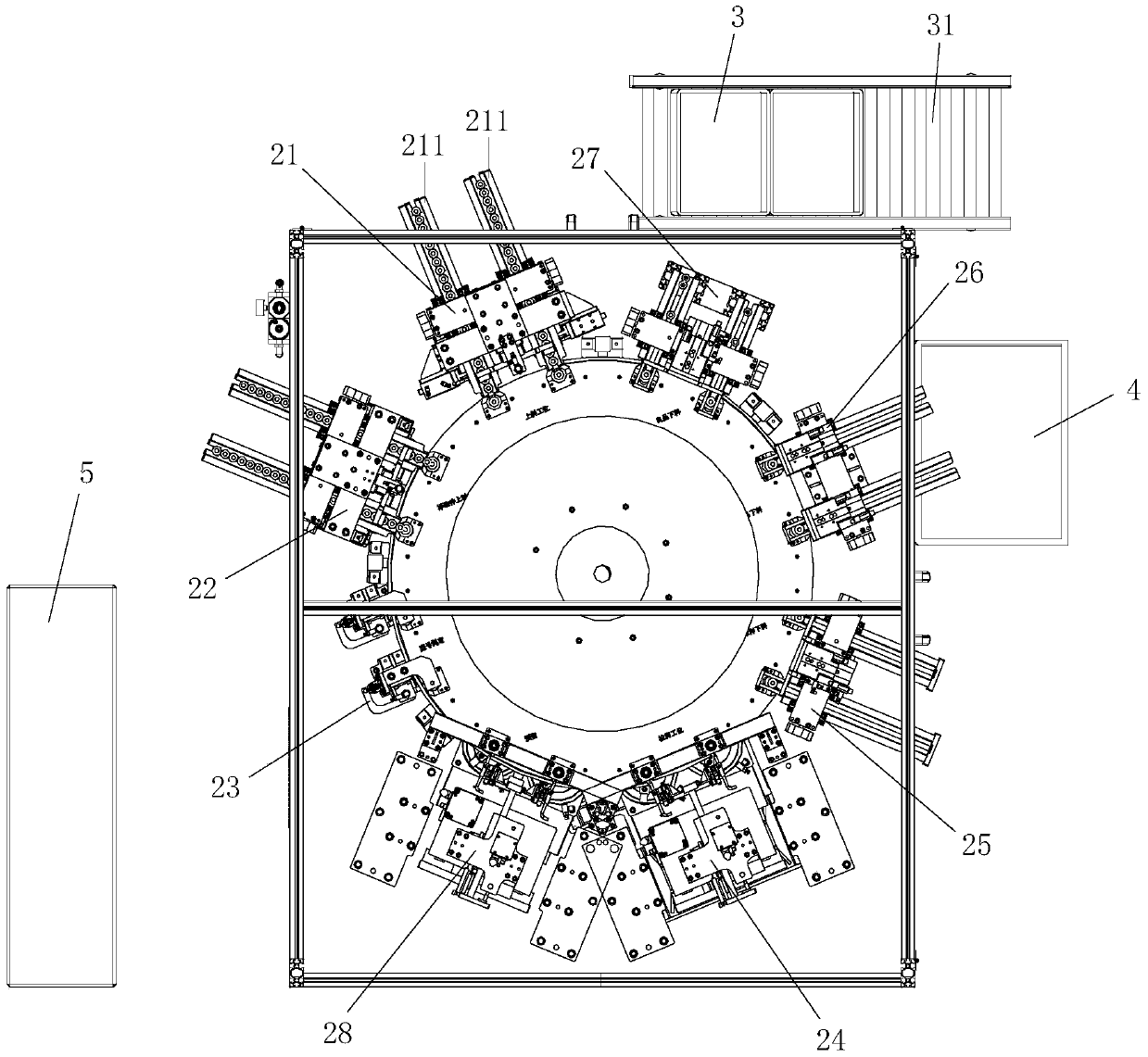

[0028] Such as figure 1 with figure 2 As shown, the present invention describes an eddy current testing device for long ball pins, which includes an outer shell 1 and a turntable 2 inside it.

[0029] Preferably, a qualified box 3, an unqualified box 4, and an electrical cabinet 5 are provided outside the outer shell 1; wherein the qualified box 3 is located directly below the qualified product blanking mechanism 27, and one side of the qualified box 3 is provided with Qualified product conveyer belt 31, so that qualified product is collected and processed; Unqualified box 4 is then positioned at the right below of unqualified product unloading mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com