Metal material corrosion testing device and method under high-pressure densely-compacted bentonite environment

A technique for metal materials, corrosion testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

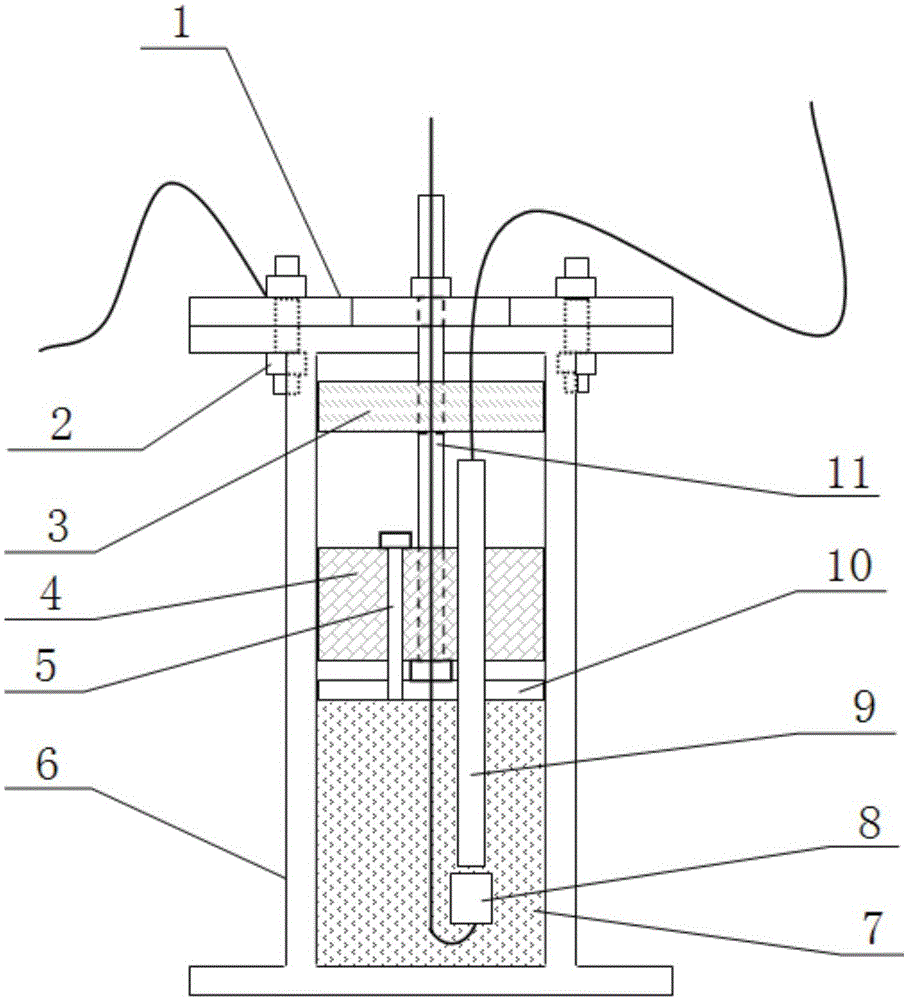

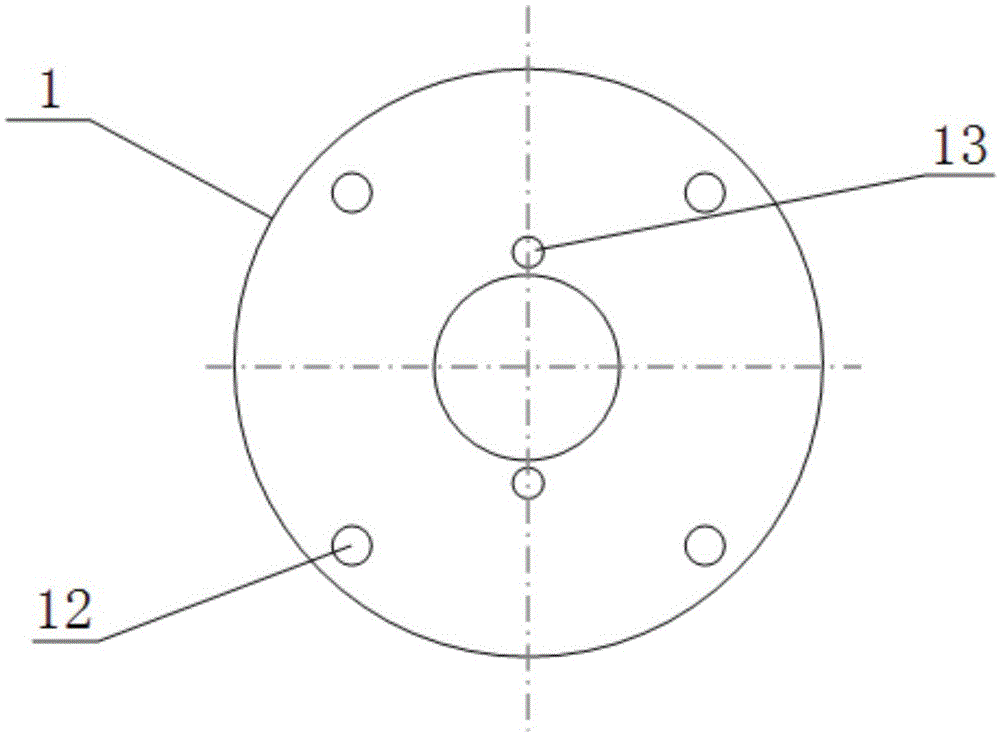

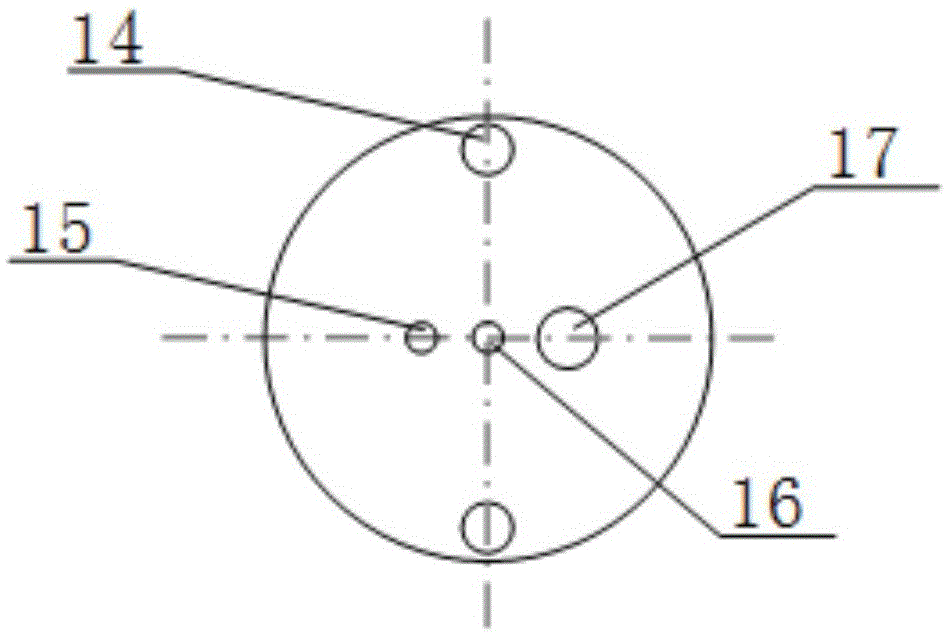

Examples

preparation example Construction

[0041] 1) Preparation of bentonite with different saturations: Weigh a certain amount of bentonite as a buffer backfill material, bake it in an oven at a specific temperature to constant weight, calculate its initial moisture content, and place the dried soil sample in a desiccator for use; There is a certain correspondence between saturation and water content, and its different saturation can be expressed by its water content. According to the chemical composition of the groundwater in the pre-selected area of the high-level radioactive waste storage, select the appropriate salt and dissolve it in double distilled water to prepare the groundwater solution with the required concentration, and adjust its pH with acid and alkali to obtain the groundwater solution prepared in the laboratory. Wet the dried bentonite with groundwater and maintain it by spraying method, and then obtain bentonite with different saturation;

[0042] 2) Preparation of high-compacted bentonite: use th...

Embodiment

[0047] Below in conjunction with exemplary embodiment of the present invention describe in more detail the corrosion test method of metal material under the environment of high compacted bentonite of the present invention, comprise the steps:

[0048] First of all, according to the chemical composition and content of the groundwater in the pre-selected area of the high-level nuclear waste storage in my country, the groundwater solution for the laboratory is prepared, and the main salts include NaCl, Na 2 SO 4 , NaHCO 3 、NaNO 3 , CaCl 2 , MgSO 4 , KCl, etc., are dissolved step by step with double distilled water, and then adjusted to the average value of the region with acid or alkali. The laboratory prepares groundwater as the subsequent bentonite wetting solution.

[0049] Then dry the selected bentonite and store it in a dry box. According to the prediction curve of the relationship between the saturation of bentonite on the surface of the high-level radioactive nuclea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com