Detection device and method for low-temperature stop valve

A detection device and shut-off valve technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as inconvenient sealing, and achieve the effect of simple and portable detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

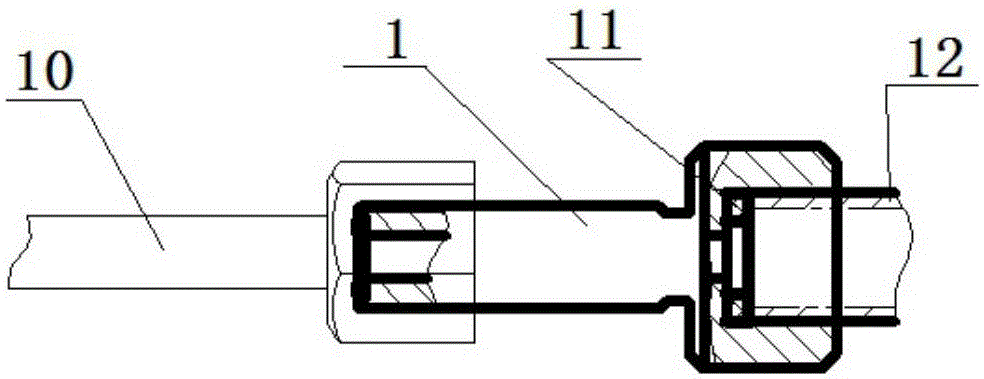

[0024] A detection device for low temperature stop valve, such as figure 2 Shown, including:

[0025] Used to connect the first side plate 2 of the sealed steel pipe end, the screw connection seat 1 (including O-shaped rubber ring, rubber backing plate) is connected to the first side plate 2 through threads, and one end of the screw connection seat 1 is connected to the detection end through threads, It is sealed with O-shaped rubber ring, the other end is connected to the steel pipe of the shut-off valve 9 and sealed with a rubber backing plate;

[0026] A fixed bottom plate 3 with slide rails for fixing two side plates 2, 8 can be installed on a fixed detection bracket or used for mobile detection;

[0027] The screw seat 4 (including O-shaped rubber ring, screws, pressure plate, etc.) used to detect and fix the threaded end of the low-temperature shut-off valve 9 is sealed with O-shaped rubber ring for the connection with the valve threaded end;

[0028] Used to detect the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com