Wavefront sensor and wavefront measuring method

A wavefront sensor and wavefront measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of difficulty in manufacturing random coded amplitude gratings, and achieve the effects of low manufacturing cost, high interference contrast, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

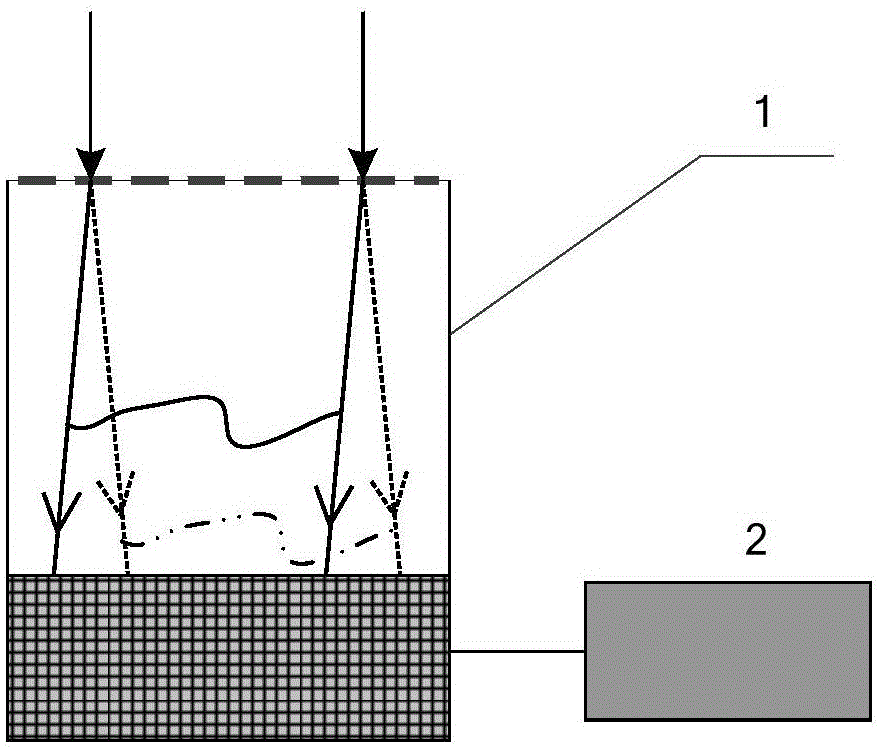

[0027] A wavefront sensor 1, comprising a two-dimensional randomly coded hybrid grating 101 and a detector 102;

[0028] The two-dimensional randomly coded hybrid grating 101 is a two-dimensional grating with the same grating period in the x and y directions, and is composed of a randomly coded amplitude grating 1011 with a period of 50 μm and a checkerboard phase grating 1012 with a period of 100 μm. The period T of the grating 101 is 100 μm, the central wavelength of the checkerboard phase grating 1012 is 532 nm, the duty cycle is 50%, the phase change of adjacent phase units at the central wavelength is π, the distance between the detector CCD102 and the grating 101 The spacing is 1 cm, and the aperture of the wavefront sensor 1 is 1 cm.

[0029] The randomly coded amplitude grating 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com