High-efficient radiating system applicable to multiple point heat sources in small space

A heat dissipation system and small-space technology, applied in the field of aerospace thermal control, can solve problems such as the inability to solve the heat dissipation requirements of high-power phased array antennas, poor reliability and stability of mechanical pumps, and occupying space resources, so as to save power and temperature The effect of good operation and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

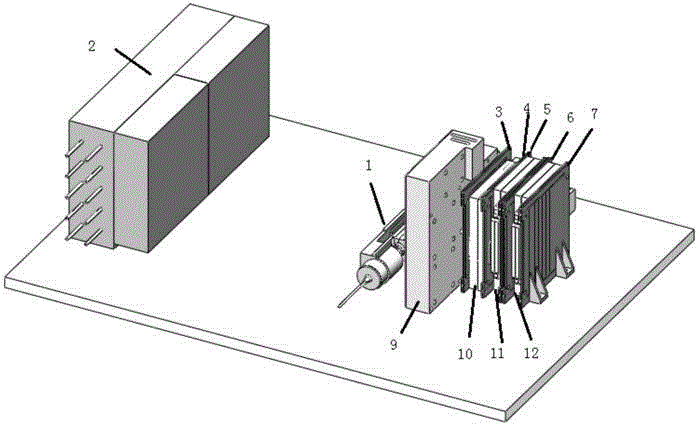

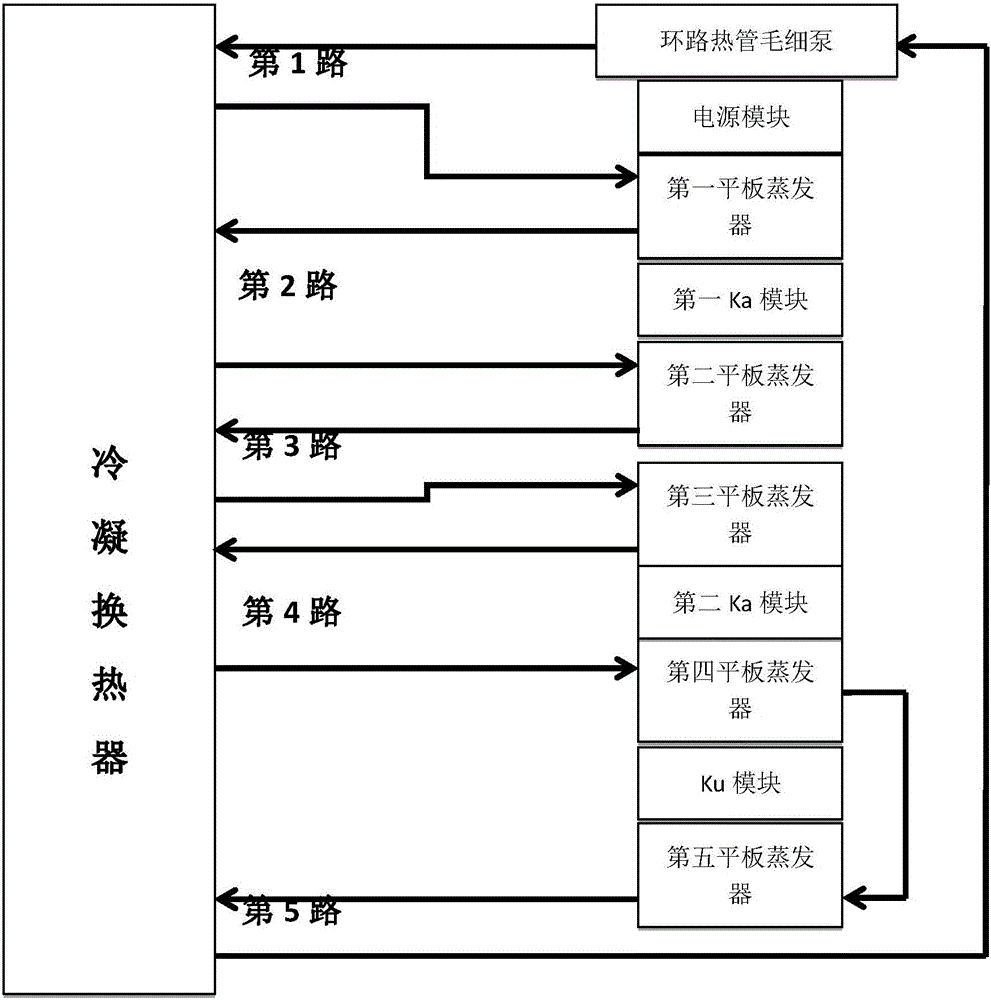

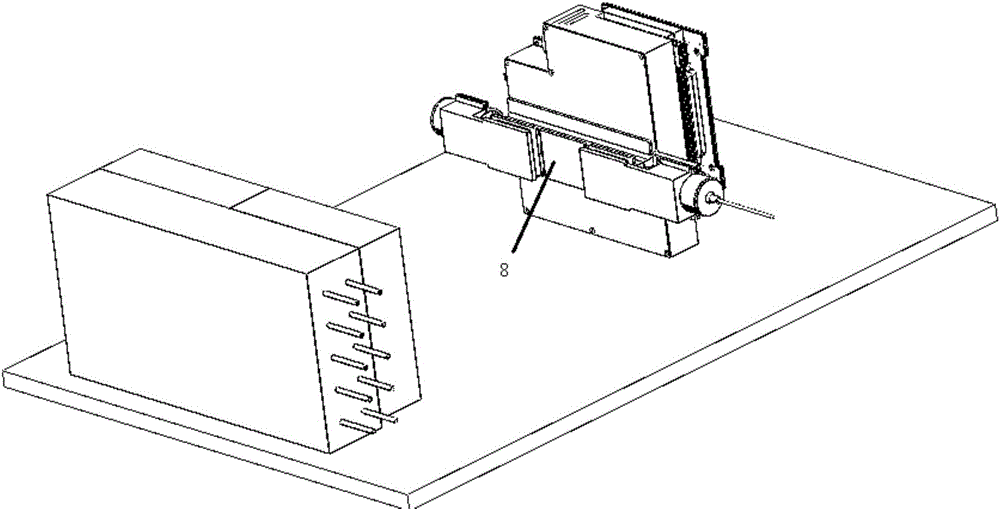

[0017] as attached figure 1 and 2 As shown, the present invention is used to dissipate heat on the power amplifier module and the power module on the phased array antenna, that is, the point heat source; because the volume of the phased array antenna assembly is small and the power is large, multiple heat sources work at the same time, such as the phased array antenna assembly. The total heat consumption of the power amplifier module and power module of the control array antenna has reached 1000W.

[0018] The heat dissipation system of the present invention includes a loop heat pipe capillary pump 1, a steam pipeline, a liquid pipeline, a condensation heat exchanger 2, a first flat evaporator 3, a second flat evaporator 4, a third flat evaporator 5, a fourth Flat plate evaporator 6, fifth flat plate evaporator 7 and auxiliary drive heater 8; peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com