Improved gas extraction structure adopting downward hole drainage and implementation method thereof

A technology of gas drainage and drainage pipes, which is applied in drainage, gas discharge, mining equipment, etc., can solve problems affecting the effect of gas drainage, achieve efficient mining and utilization, reduce gas flow resistance, and reduce gas drainage cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

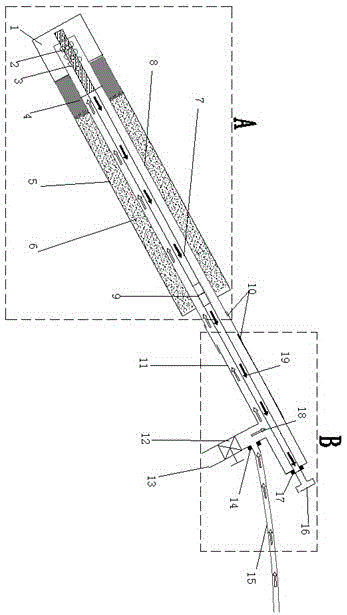

[0020] Such as figure 1 As shown, a structure for improving gas drainage with a vertical hole drainage, which includes the structure in the hole (A) connected with the drainage device (B) outside the hole through the connection part 10 inside and outside the hole, and the structure in the hole (A) includes a gas collection Chamber 1 is in communication with extraction pipe 8. Gas collection chamber 1 is located at the front end of the hole structure (A). Drainage pipe 8 passes through Mali loose cotton yarn plugging section 4 and grouting plugging section in sequence from one end of gas collection chamber 1 to the outside. 6 is fixed; the drainage pipe 7 is set in the extraction pipe 8; the drainage device outside the hole (B) includes the connection pipe 11 of the extraction pipe connected with the extraction pipe 8, and the length of the outer hole of the drainage pipe 7 is the same as that of the connection pipe 11 of the extraction pipe , the outer port of the drain pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com