Freezing Shimen Uncovering Coal Method Based on Hydraulic Slit

A technology of hydraulic slitting and coal removal in Shimen, which is applied in hydraulic mining, earthwork drilling, gas discharge, etc., can solve the problems of reduced coal strength in the area where coal is removed, limited diffusion radius of cement slurry, and inability to achieve regional reinforcement. Achieve the effect of reducing the number of gas drainage drilling holes, eliminating the risk of outburst, and reducing the risk of outburst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] The method for uncovering coal in the freezing type stone gate based on hydraulic cutting of the present invention has the following steps:

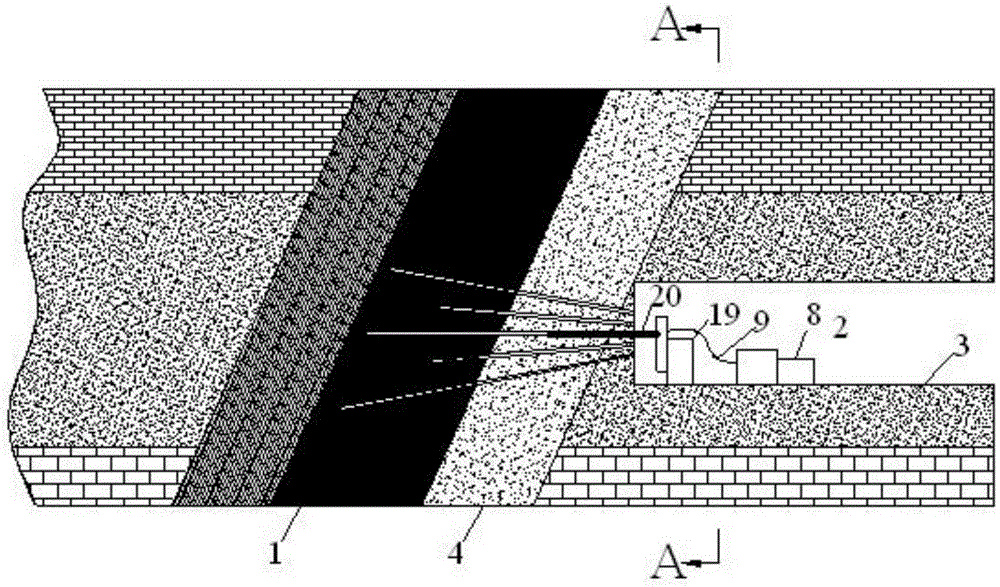

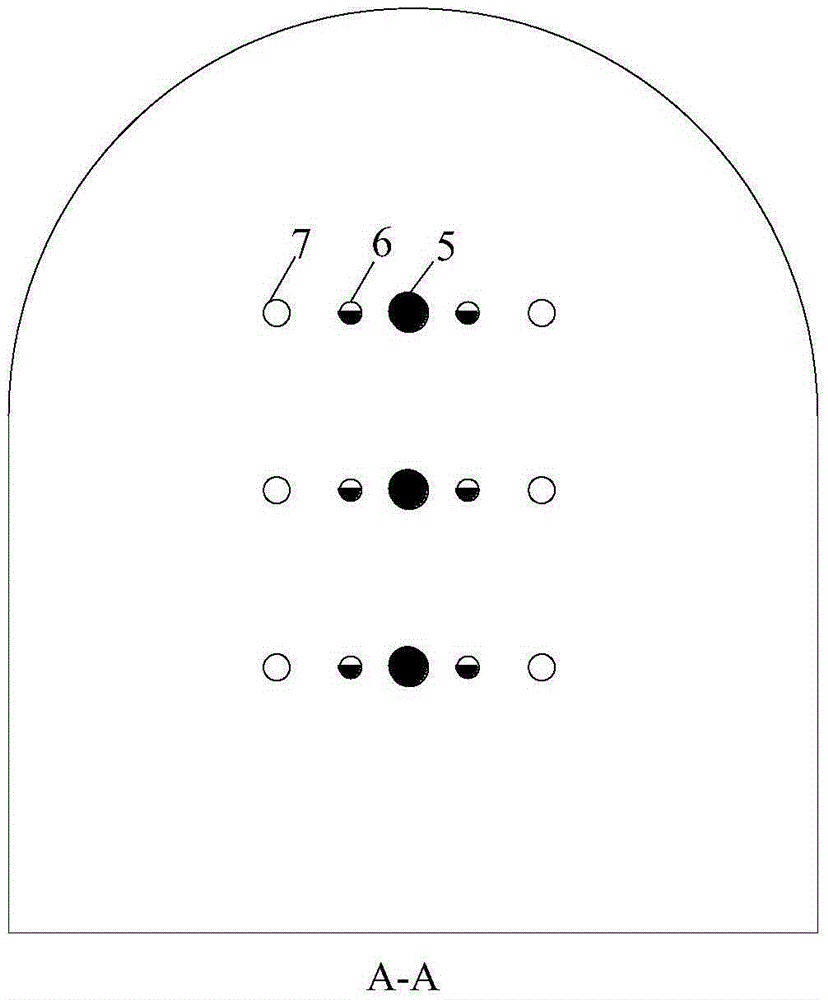

[0023] a. At the position where the minimum normal distance between the working face 2 and the coal seam 1 of the rock roadway 3 is greater than or equal to 7m, pass through the protective rock pillar 4 and construct multiple water injection holes 5 at intervals in the direction of the coal seam 1, completely penetrating the target coal seam 1 , aperture 75 ~ 130mm;

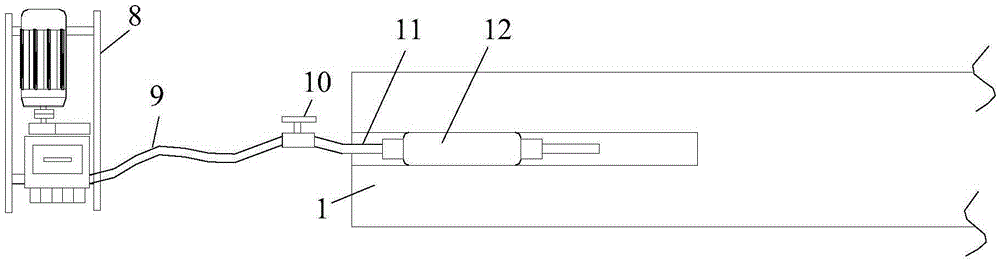

[0024] b. Use the drill rig 19 to drive the through-hole drill pipe 20 with high-pressure seal to the set position of the slotted hole 5, start the drill rig 19 and the high-pressure water injection pump 8 at the same time, and pass the through-hole drill pipe with high-pressure seal in the drill hole 5 20 Cut the coal body around the borehole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com