Quick coal mining method used for controlling ground deformation

A coal mining method and surface deformation technology, applied in surface mining, underground mining, earth drilling and mining, etc., can solve problems such as inability to effectively control surface deformation, inability to ensure underground mining safety, inability to ensure ground safety, etc., to achieve control of subsurface The effect of reducing weight, improving the recovery rate of coal resources, and reducing the intensity of mine pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The described rapid coal mining method for controlling surface deformation comprises the following steps:

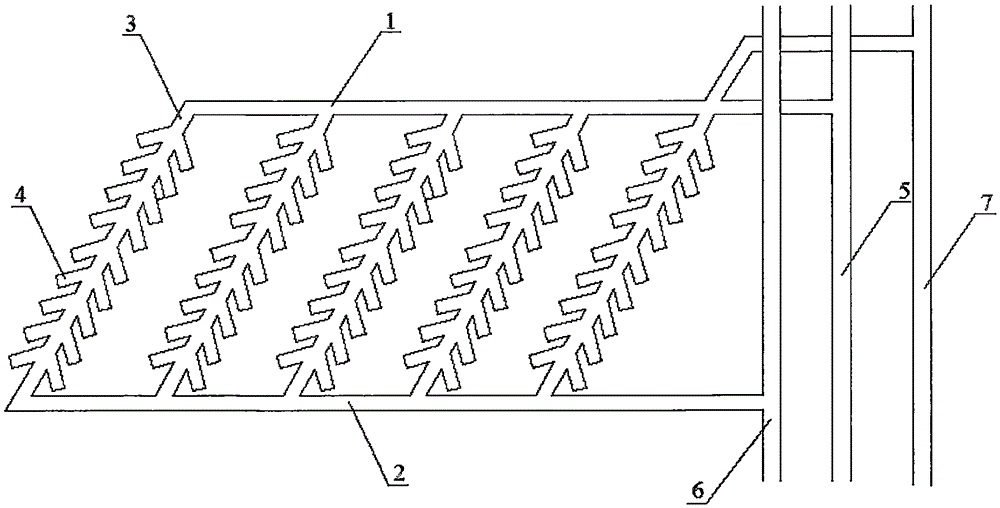

[0038] (a) Excavate the working face transportation lane 1 and the working face return air lane 2 in the pre-mining working face, the working face transportation lane 1 opens at the mine transportation roadway 5, and ends at the predetermined position of the first mining branch roadway 3 , the return air lane 2 of the working face opens in the mine return air main lane 6, and ends at the position of the predetermined first extraction branch lane 3;

[0039] (b) Excavate the mining branch roadway 3 described in the first one, running through the transportation roadway 1 of the working face and the air return roadway 2 of the working face;

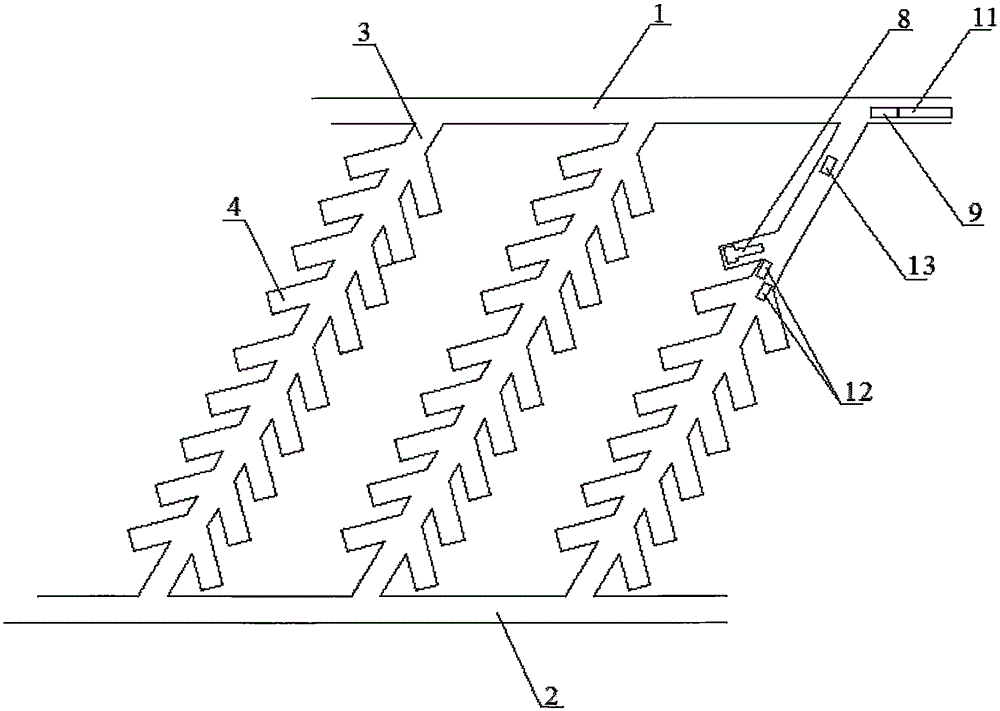

[0040] (c) Coal mining equipment 8, reloading equipment 9, transfer equipment, transportation equipment 11 and support equipment 12 are arranged in the mining branch roadway 3 and the working face transportation roadway 1;

[0...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is:

[0052] In this example, when step (d) is completed, the driving of the next mining branch roadway 3 is carried out at a predetermined interval, and the excavation of the mining tunnel 4 in the previous mining branch roadway 3 is always maintained. The excavation of next described mining branch roadway 3 is carried out simultaneously.

[0053] In this example, the transfer equipment is a coal truck 13, the coal mining equipment 8 is arranged in the mining branch roadway 3, and the transfer equipment 9 and the transportation equipment 11 are arranged in the working face transportation roadway 1 and connected, the coal truck 13 transports the coal mined by the coal mining equipment 8 to the reloading equipment 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com