Method for quickly setting up main ropes of suspension bridge

A technology for suspension bridges and main cables, applied in suspension bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of low cost, achieve the effects of convenient equipment transportation, conducive to selection and cost control, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

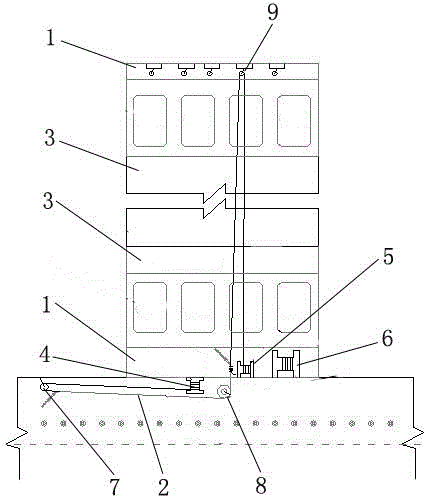

[0035] A method for quickly erecting main cables of a suspension bridge, comprising the following steps:

[0036] In the first step, before pouring the anchorage concrete on the opposite bank, a plurality of ground anchor wire ropes and a plurality of alloy tie rods 13 are pre-embedded in the anchorage rear wall 1, and the No. 2 diverting pulley 9 and the fixed pulley block 10 are fixed by the ground anchor wire ropes.

[0037] In the second step, on the construction bank, the wire rope of the No. 1 winch 4 is connected to the fixed end of the coiled main rope 2 after passing through the No. 1 diverting pulley 7, and the No. 1 winch 4 is started to straighten the main rope 2 on the construction bank. And paste the reflective film at the mid-span position of the main cable 2.

[0038] In the third step, on the construction bank, the wire rope of the No. 2 hoist 5 is pulled to the opposite bank by the working cable, and returns to the construction bank after passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com