Hydraulic turnover plow with deep scarification function

A hydraulic flipping and functional technology, applied in the field of agricultural machinery, can solve the problems of wasting resources and low operating efficiency, and achieve the effects of saving resources, high operating efficiency, and ensuring structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

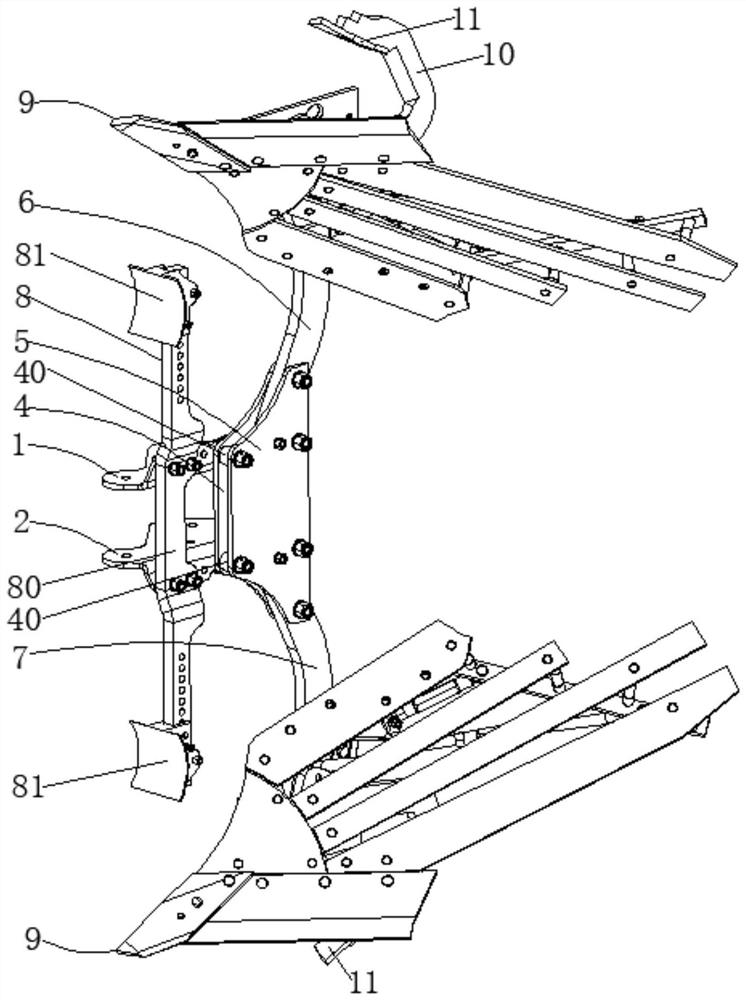

[0049] In the hydraulic reversible plow with deep loosening function, the small plow assembly 8 is fastened to the front ends of the plow seat plate 1 and the plow seat plate 2 2. It is connected with the end of the plow post two 7 to realize the operation of turning the soil; the ends of the first plow post 6 and the two plow post 7 are connected with a subsoiling shovel 10, and the subsoiling shovel 10 is provided with a subsoiling sheet 11.

[0050] First, the tractor operates at one time, that is, the soil is turned over and the straw is buried, and the subsoiling operation of the plow layer is completed, which reduces the number of times the tractor enters the ground at one time, and has high operating efficiency and saves resources.

[0051] Second, the depth of digging is generally 20-30cm. In this way, the depth of digging does not need to be too deep. For example, the depth of digging is 30cm, and then the subsoiling sheet 11 subsoiling operation only needs about 10cm....

Embodiment 2

[0053] On the basis of Example 1, a splint spacing sleeve 40 is provided between the plow column splint one 4 and the plow column splint two 5, which ensures that the plow column splint one 4 and the plow column splint two 5 are fastened to the plow column one 6 And the structural stability of plow post II 7 under force.

[0054] The small plow assembly 8 includes a small plow post 80 and a small plow share 81, the small plow post 80 is fastened to the plow seat plate 1 and the plow seat plate 2 2, and the small plow share 81 is provided with two, and respectively fastened with the ends of the small plow column 80, and the height position of the small plow share 81 on the small plow column 80 is adjusted according to the height of the stalks. In the ditch where the soil is turned over, it is then covered by the plow blade assembly behind to ensure that the straw is completely buried and covered.

Embodiment 3

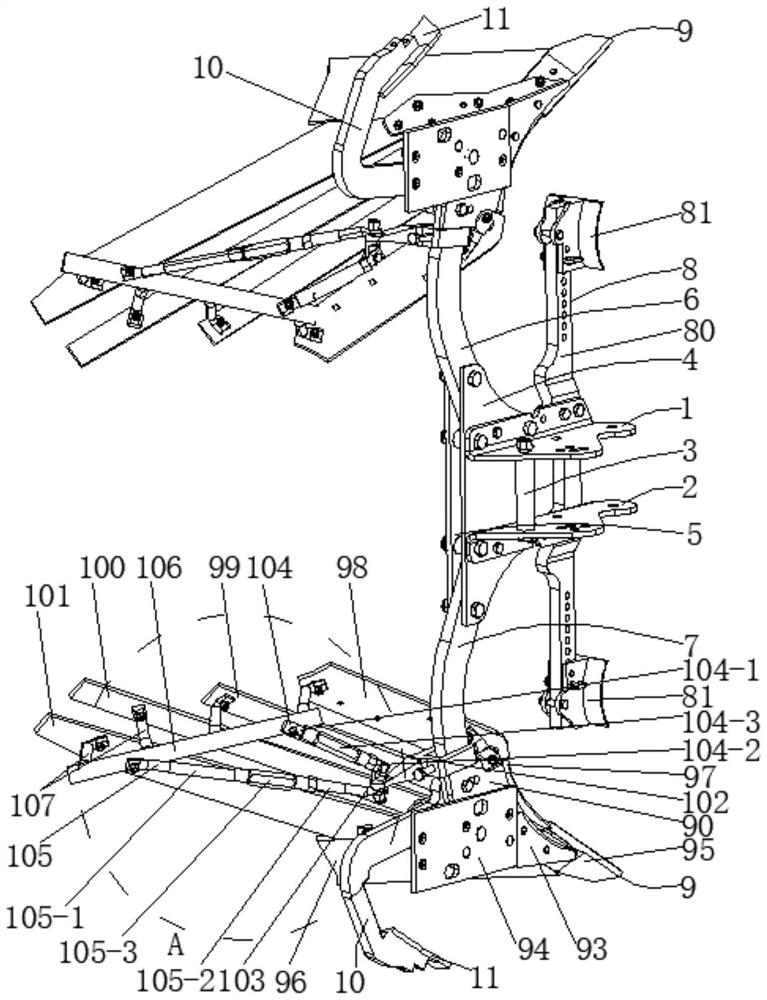

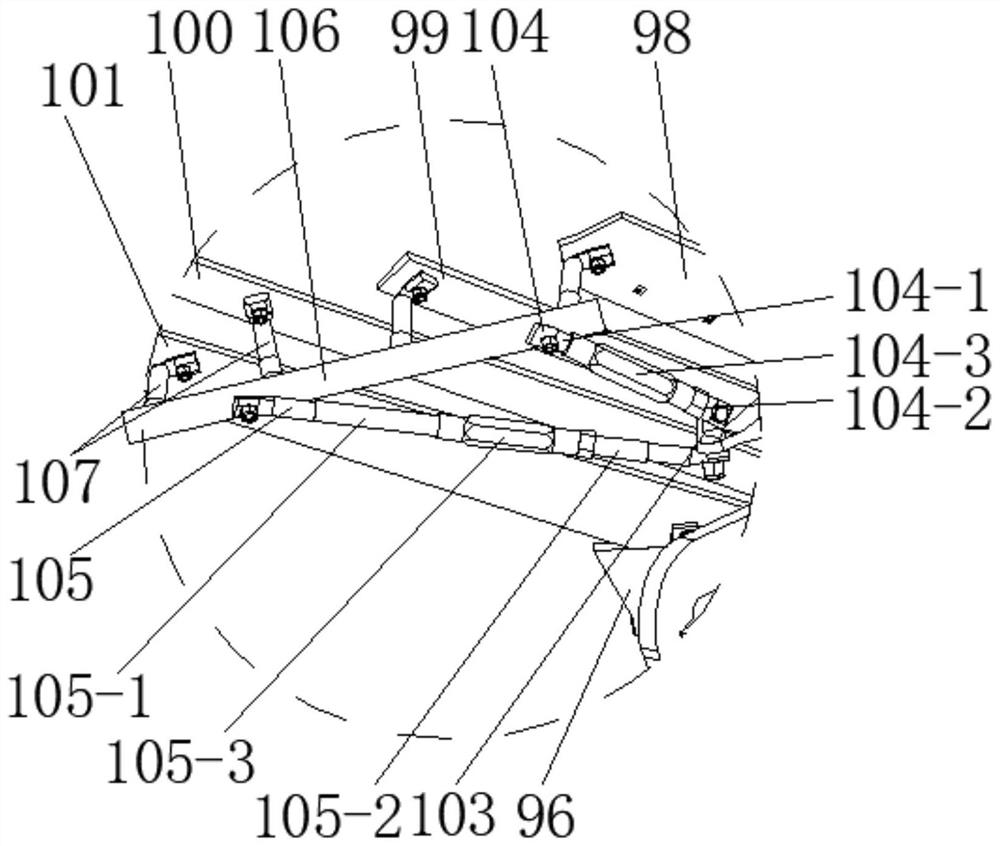

[0056] The plow blade assembly 9 includes a plow point plate 90, a plow support plate 91, a support arc plate 92, a side knife 93, a plow sub-plate 94, a plow point 95, a coulter 96 and an arc plate 97. The plow support plate One end of 91 is fastened to the plow point plate 90, and the other end is fastened to the supporting arc plate 92. The side knife 93 is fastened to the side of the front end of the plow point plate 90. The end side is tightly connected, the plow point 95 is tightly connected to the front end of the arc supporting plate 92, the coulter 96 is tightly connected to the rear end of the arc supporting plate 92, and the arc plate 97 is tightly connected to the arc supporting plate 92 , forming a fixed part for cutting and turning over soil.

[0057] The supporting arc plate 92 is sequentially fastened and connected with the upper plow blade 98, the upper plow blade 99, the upper plow blade 3 100 and the upper plow blade 4 101 from top to bottom. The support ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com