Preparation method of high-quality cape jasmine seed oil rich in linoleic acid

A gardenia seed, high-quality technology, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc. The effect of low solvent consumption and no solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

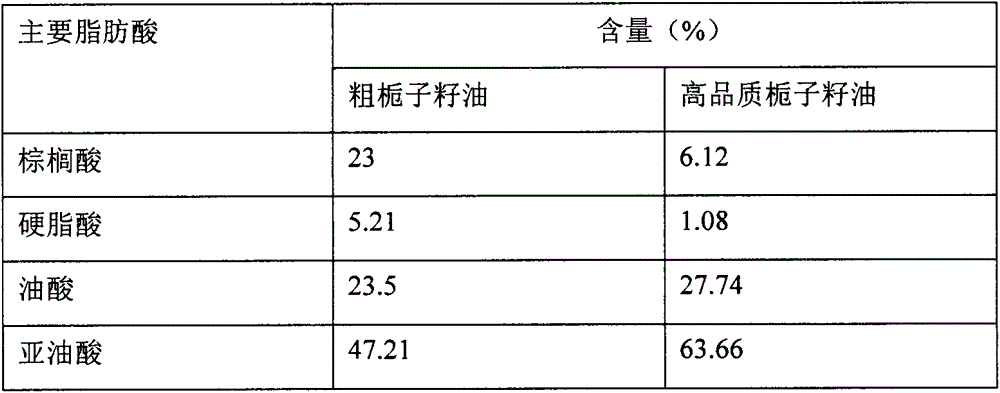

[0024] Dehull the gardenia seeds, dry them in a microwave at a power of 1.2kW, the thickness of the gardenia seeds is 5-10cm, dry for 1.0h, crush the dried gardenia seeds, put them into the extraction kettle, inject propane for extraction The kettle is mixed with gardenia seed raw materials, the mass volume ratio of propane to raw materials is 1:5~1:8 (g:mL), and 2~3 times, each time for 0.5-1.0h, after the extraction is completed, the propane carrying gardenia seed oil is transported to the separation kettle, and then evaporated under reduced pressure to fully vaporize the propane. During the evaporation process, the temperature is controlled at 30-50°C. After the recovery of propane is complete, the extracted crude gardenia seed oil is discharged from the bottom of the separation tank, the yield is 15-20%, the color is orange, and the fatty acid composition is analyzed by GC-MS. The crude gardenia seed oil is used as a raw material, diatomaceous earth and activated carbon ar...

Embodiment 2

[0026] The gardenia seeds are shelled, and the power of microwave drying is 0.1-1.5kW, the thickness of the gardenia seeds is 5-10cm, and the drying time is 0.5-2.0h. The dried gardenia seeds are crushed and put into the extraction kettle. Inject butane into the extraction kettle and mix it with gardenia seed raw materials. The mass volume ratio of butane to raw materials is 1:5~1:8 (g:mL). Under the same conditions, extract 2 to 3 times, each time for 0.5 to 1.0h. After the extraction is completed, the butane carrying the gardenia seed oil is transported to the separation tank, and then evaporated under reduced pressure to fully vaporize the butane. The evaporation process Control the temperature at 30-50°C. After the recovery of butane is complete, release the extracted crude gardenia seed oil from the bottom of the separation tank. The yield is 15-20%, the color is orange, and the fatty acid composition is determined by GC-MS analyze. The crude gardenia seed oil is used as...

Embodiment 3

[0028] The gardenia seeds are shelled, and the power of microwave drying is 0.1-1.5kW, the thickness of the gardenia seeds is 5-10cm, and the drying time is 0.5-2.0h. The dried gardenia seeds are crushed and put into the extraction kettle. Inject dimethyl ether into the extraction kettle and mix it with gardenia seed raw materials. The mass volume ratio of dimethyl ether to raw materials is 1:5-1:8 (g:mL). The extraction temperature is 30-50°C and the extraction pressure is 0.6-0.8 Under the condition of Mpa, extract 2 to 3 times, each time for 0.5 to 1.0h. After the extraction, the dimethyl ether carrying the gardenia seed oil is transported to the separation kettle, and then evaporated under reduced pressure to fully gas the dimethyl ether. During the evaporation process, the temperature is controlled at 30-50°C. After the recovery of dimethyl ether is complete, the extracted crude gardenia seed oil is released from the bottom of the separation kettle. The yield is 15-20%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com