Gasoline Processor for Petrol Station

A processor and gasoline technology, applied in the direction of electric/magnetic refining, etc., can solve the problems of unfavorable popularization, low gasoline magnetization rate, and high price, and achieve the effects of reducing fuel consumption, improving combustion performance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

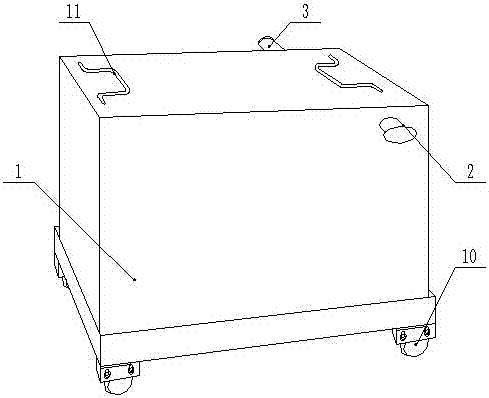

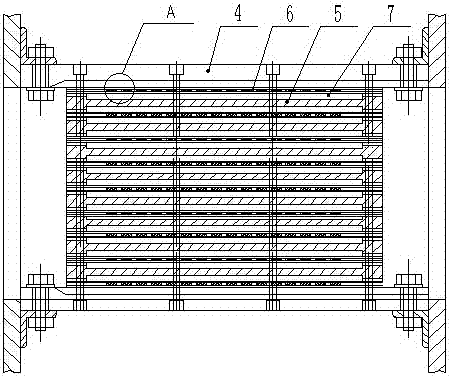

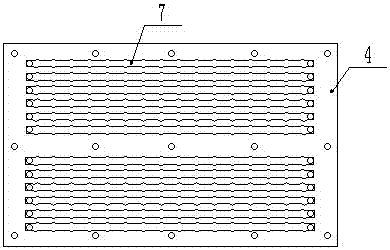

[0022] Such as Figure 1-Figure 8 As shown, the gasoline processor for the oil station includes a closed box body 1, an oil inlet port 2 and an oil outlet port 3 are arranged on the corresponding two sides of the box body body 1, and an oil treatment module is fixedly arranged inside the box body body 1. The oil processing module includes two upper and lower single-sided magnetic guide plates 4, and eight double-sided magnetic guide plates 5 are arranged between the two single-sided magnetic guide plates 4. And between the double-sided magnetic conductive plates 5, plastic partitions 6 are arranged, the single-sided magnetic conductive plates 4, the double-sided magnetic conductive plates 5 and the plastic partitions 6 are fastened and connected by bolts, and the single-sided magnetic conductive plates 4 The inner surface and the two planes of the double-sided magnetic guide plate 5 are all provided with a plurality of longitudinal oil passage grooves 7, one end of the oil pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com