System capable of achieving extending and adjusting of belt body

A technology of belt body and box body, applied in the system field, can solve the problems of conveyor belt jamming, device internal jamming, conveyor belt loosening, etc., and achieve the effect of preventing the conveyor belt from loosening, high accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

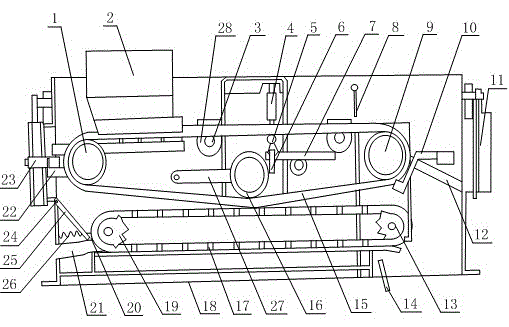

[0013] Such as figure 1As shown, a system capable of realizing belt extension adjustment includes a hollow box 18, and the box 18 is provided with a feed port 2 and a discharge port 11 communicating with the inside of the box 18. The box 18 The driving drum 9, the tensioning drum 1 and the tensioning drum 16 are arranged in the center, the tensioning drum 16 is arranged between the driving drum 9 and the tensioning drum 1, and the tensioning drum 16 is arranged in the connection between the driving drum 9 and the tensioning drum 1. Below the line, the outer wall of the drive drum 9 is provided with a feed belt 15, and the drive drum 9, the tension drum 1 and the tension drum 16 are all in contact with the inner wall of the feed belt 15 and keep the feed belt 15 taut, the feed belt 15 is arranged between the feed port 2 and the discharge port 11, the feed port 2 is in contact with the top of the conveying belt 15, the discharge port 11 is close to the driving drum 9, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com