Rocker type suspension track for spreading machine

A paver and rack-type technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of insufficient response time, low impact frequency of supporting rollers, and small impact force momentum, etc., to improve machine performance Body stability, ensuring the grounding area, and reducing the effect of impact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

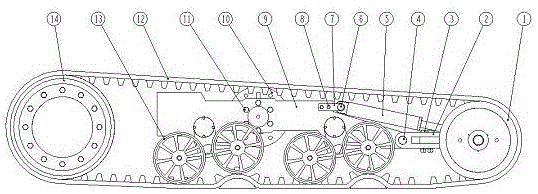

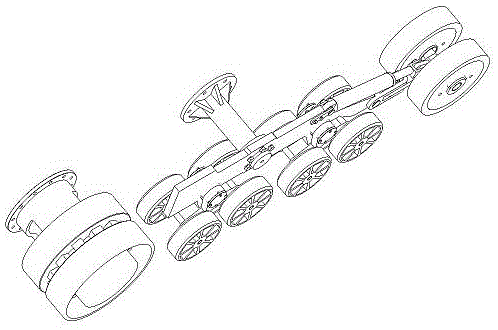

[0028] Such as figure 1 and figure 2 As shown, the present invention mainly consists of rubber track 12, and guide wheel 1 located in rubber track 12, guide wheel bracket system 2, drive wheel system 14, tension spring system 4, track beam 9, and the track beam 9 below Roller pendulum system 13 forms.

[0029] Such as Figure 8 and Figure 9 As shown, the crawler beam 9 plays the role of the overall skeleton and support, and is connected with the fuselage through the connecting frame 10 to support the fuselage.

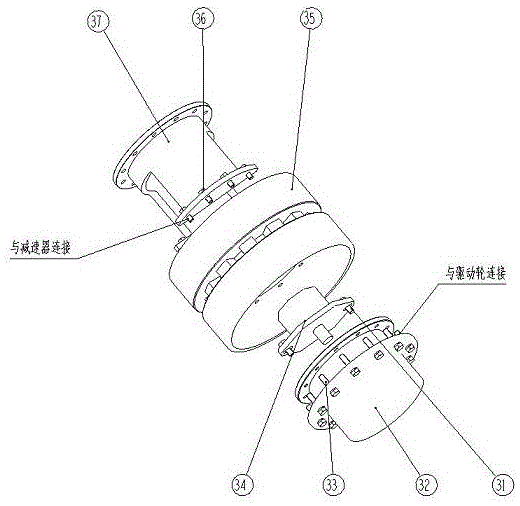

[0030] Such as image 3 As shown, the main function of the driving wheel system 14 is to drive the rubber track 12 to provide power for the whole system by rotating itself. Its main components include a driving wheel 35 , a reducer 34 , and a hydraulic motor 32 . Wherein: the hydraulic motor 32 is connected with the speed reducer 34 through the bolt 31 to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com